Buffer belt wheel and buffer gear train mechanism with same

A buffer belt and buffer wheel technology, which is applied to components with teeth, belts/chains/gears, mechanical equipment, etc., can solve the problem of reduced shock absorption capacity of the power system, reduced durability and reliability, and excessive alignment requirements of the wheel train. Advanced problems, to achieve the effect of convenient impact force transmission, compensation for alignment errors, and remarkable cushioning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The embodiments of the present invention are described in detail below. This embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following implementation example.

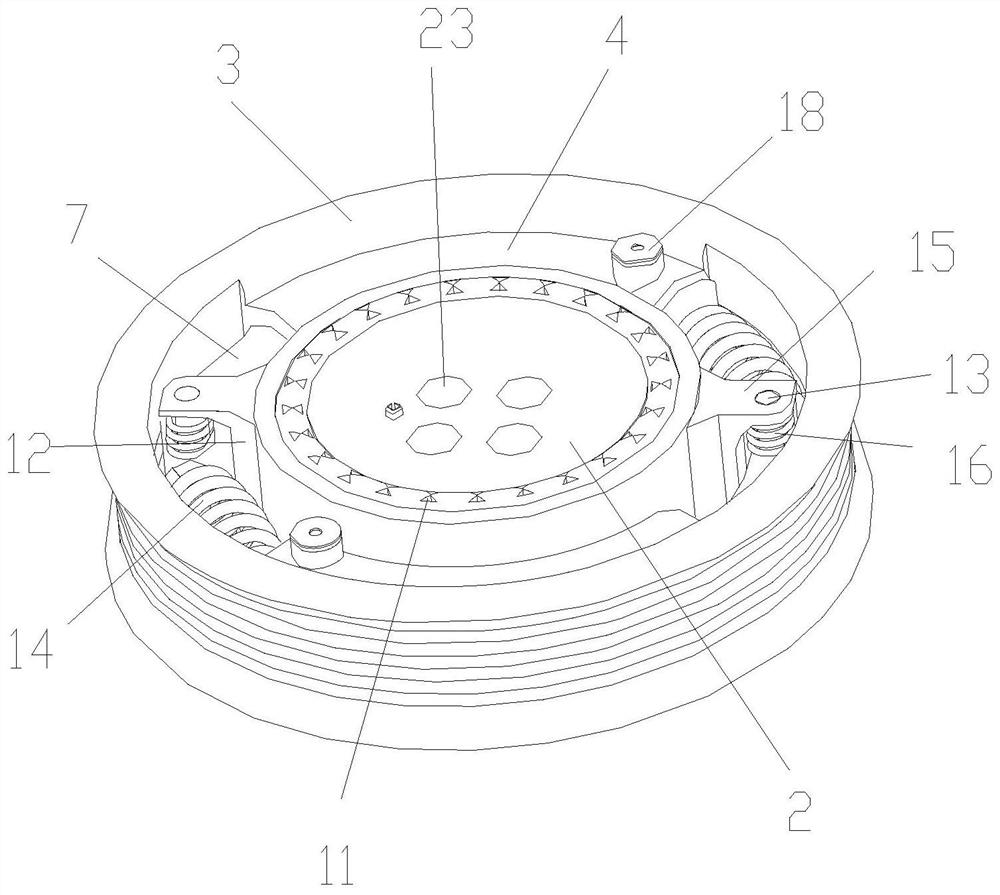

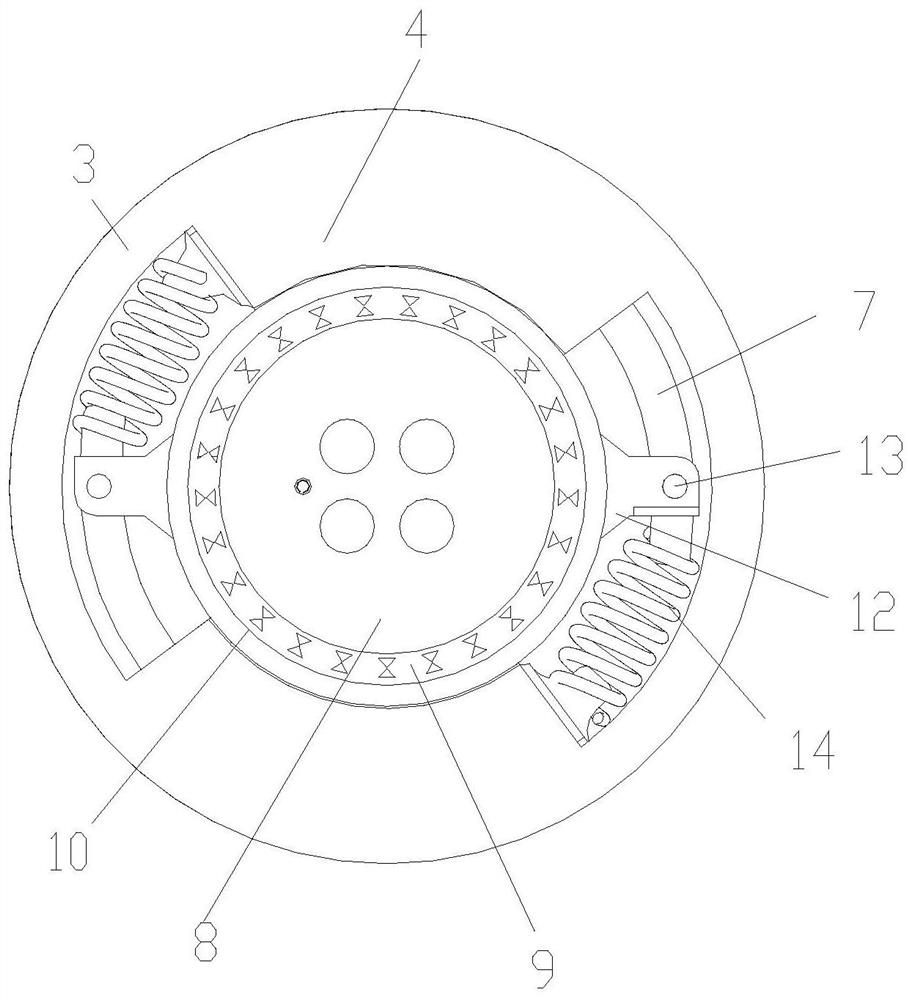

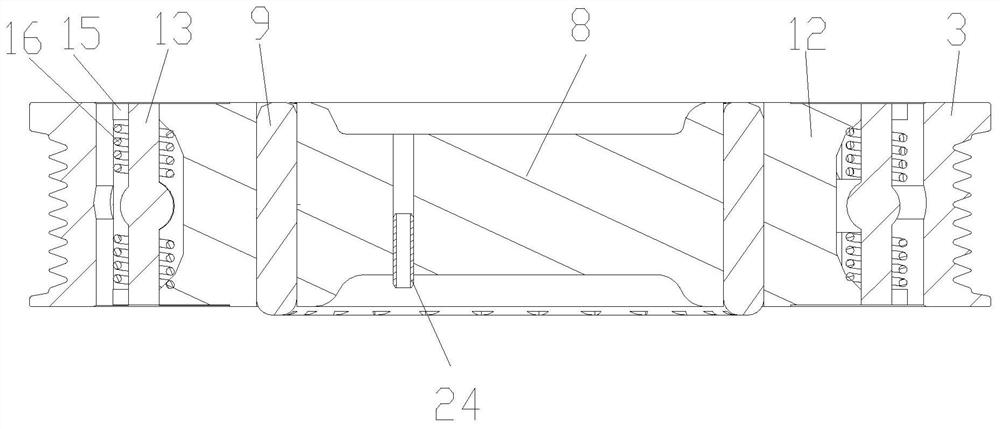

[0032] see Figure 1 to Figure 6 , this embodiment discloses a buffer pulley, comprising a buffer wheel seat 2 coaxially arranged inside and outside and a buffer wheel outer ring 3, an annular gap is formed between the outer ring of the buffer wheel seat 2 and the inner ring of the buffer wheel outer ring 3, and the ring Two cylinders 4 are arranged in the gap, and the two cylinders 4 are center-symmetrically distributed relative to the center point of the buffer pulley 1. The cylinder bodies of the two cylinders 4 are respectively fixed with the buffer wheel outer ring 3, and the cylinder bodies of each cylinder 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com