Air heat load recovery system of dry type oil-free air compressor

An air compressor and recovery system technology, which is applied in the direction of mechanical equipment, machines/engines, liquid fuel engines, etc., can solve the problems of impurities, air heat load recovery system blockage, unfavorable recovery water recycling, etc., to prevent excessive temperature , Conducive to recycling, to avoid the effect of air heat resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

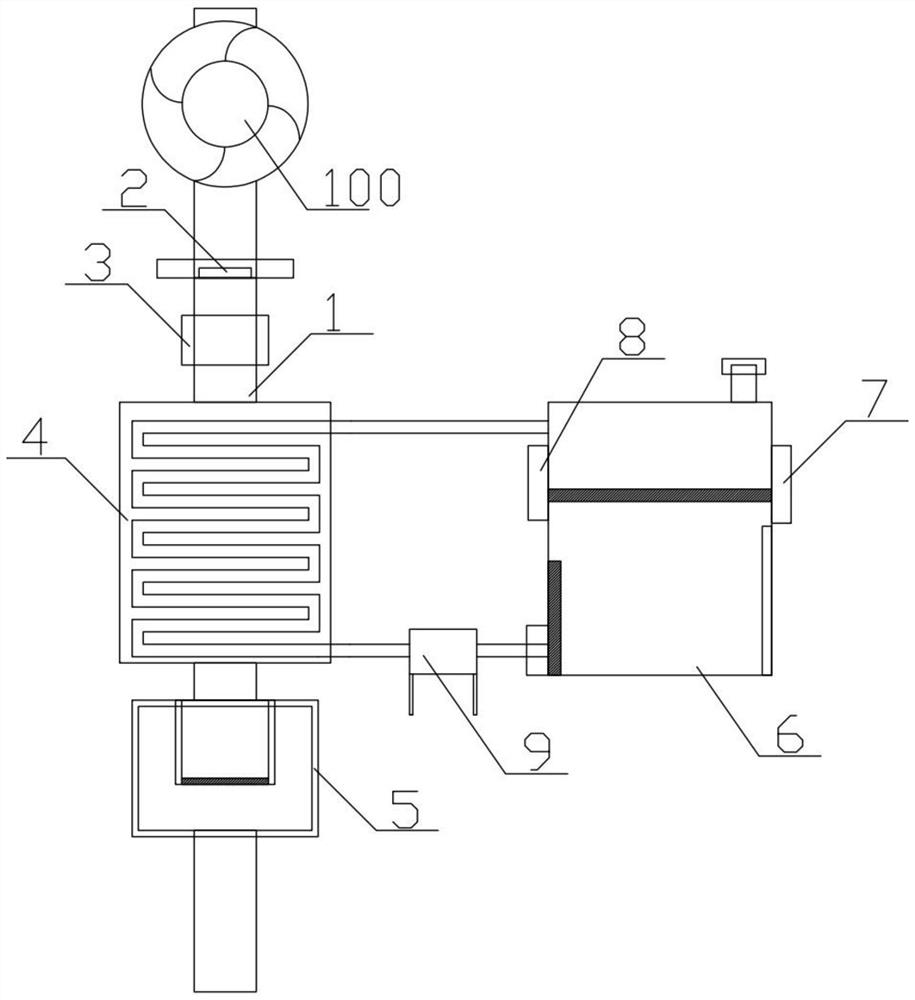

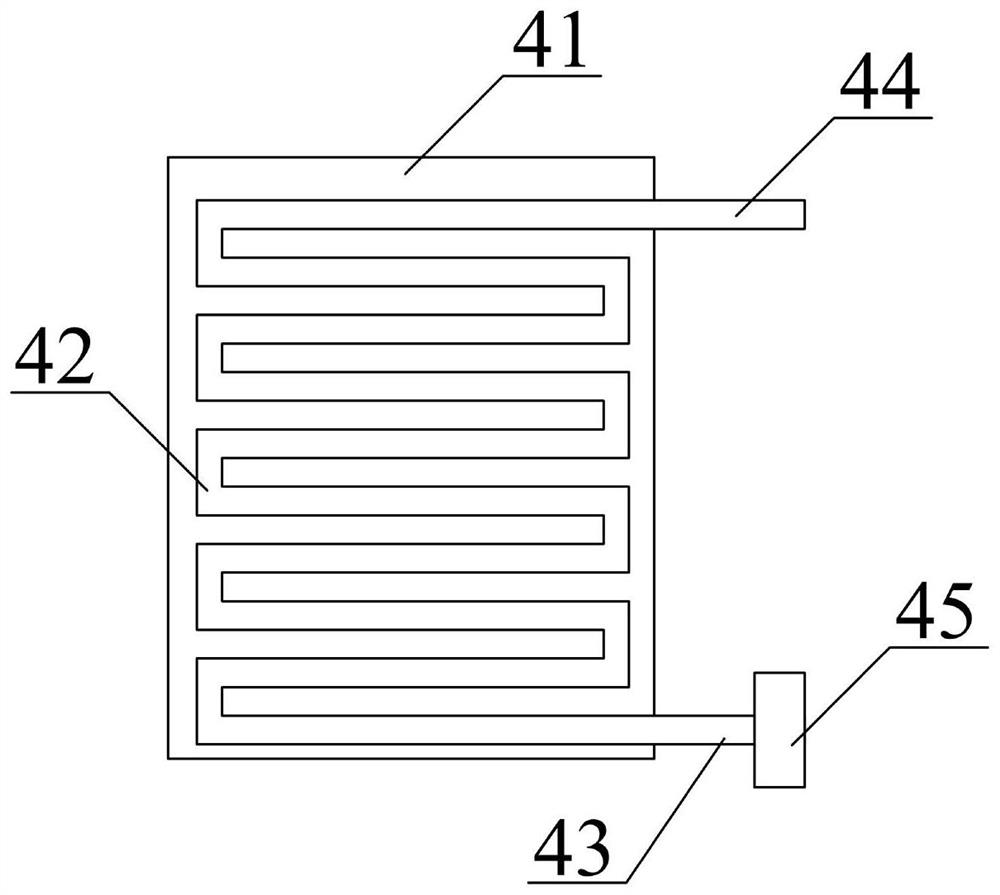

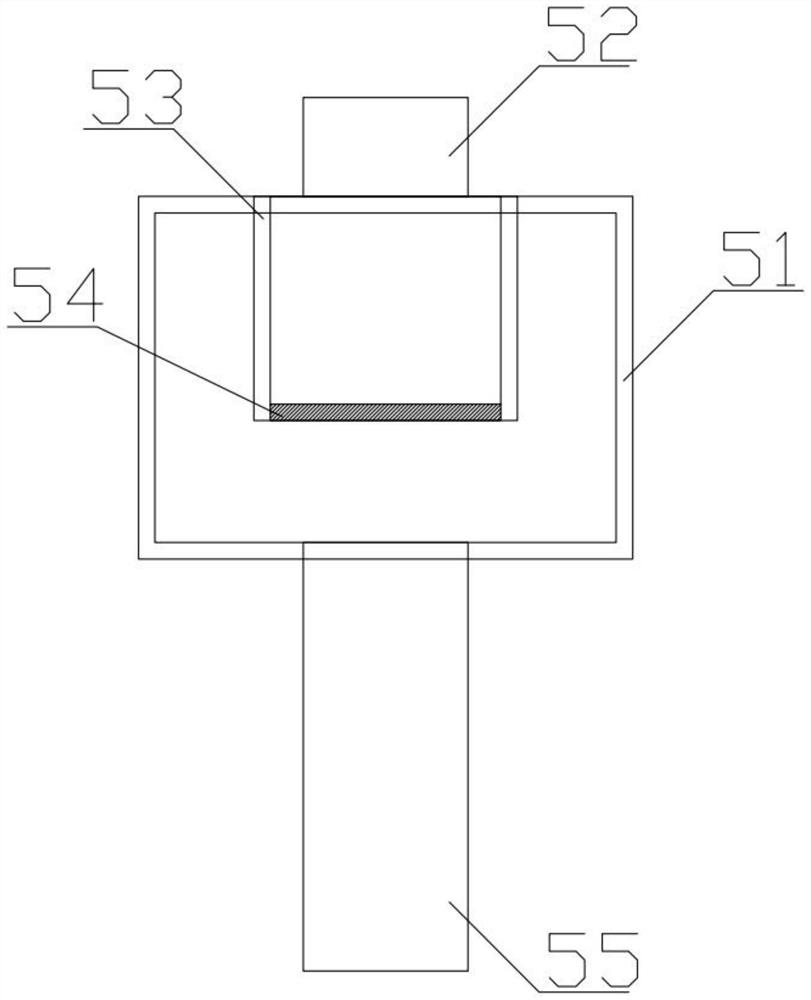

[0040] refer to Figure 1-4 , an air heat load recovery system for a dry oil-free air compressor, comprising an air intake pipe 1 and an air heat recovery assembly 4, the upper end of the air intake pipe 1 is connected to the outlet end of an oil-free air compressor 100; the air intake pipe 1 The lower end is fixedly connected to the middle position of the upper end of the air heat recovery assembly 4, the air intake pipe 1 is equipped with a solenoid valve 3, the upper part of the air intake pipe 1 is installed with a temperature sensor 2, and the lower end of the air heat recovery assembly 4 is installed with a purification assembly 5. A water supply assembly 6 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com