Brewing technology of sesame-flavor and Maotai-flavor composite liquor

A compound wine and process technology, applied in the field of liquor brewing, can solve the problems of low wine yield and high production cost, and achieve the effects of improving wine yield, harmonizing wine body and flavor, and accelerating enzymatic reaction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

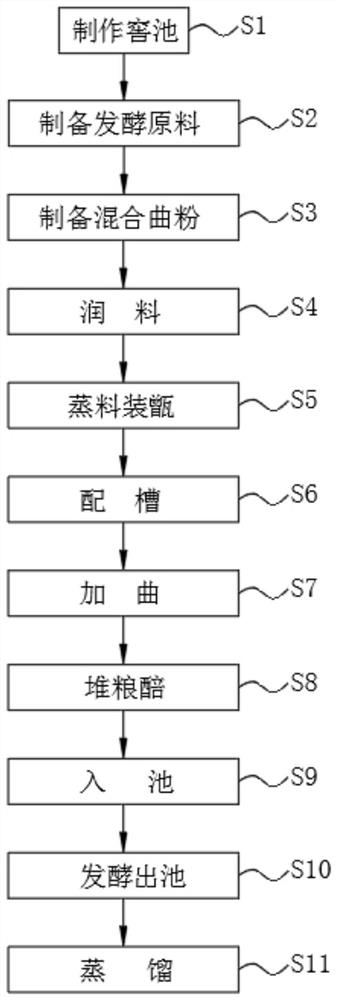

[0033] see figure 1 , the present invention provides a kind of technical scheme: a kind of brewing process of sesame sauce compound wine, comprises the following steps:

[0034] S1. Making cellar pools: Add an insulation layer to the pool wall first, then build it with red bricks, fill the gaps between the bricks with yellow mud, and lay a layer of 15cm deep yellow clay on the bottom of the pool. After laying, add high-temperature Daqu Powder 45kg, add appropriate amount of wine tail, stir evenly, let the water content reach 40%, lay it at a position 10cm higher than the upper surface of the yellow water pit, and set aside;

[0035] S2, preparation of fermentation raw materials: according to a certain ratio, prepare sorghum, wheat and bran of a certain weight ratio, sorghum and wheat are broken into 4 petals, and avoid producing fine powder, sorghum, wheat and bran are fully Mix well;

[0036] S3. Preparation of mixed koji powder: according to a certain proportion, prepare h...

Embodiment 2

[0052] see figure 1 , the present invention provides a kind of technical scheme: a kind of brewing process of sesame sauce compound wine, comprises the following steps:

[0053] S1. Making cellar pools: Add an insulation layer to the pool wall first, then build it with red bricks, fill the gaps between the bricks with yellow mud, and lay a layer of 20cm deep yellow clay on the bottom of the pool. After laying, add high-temperature Daqu Powder 55kg, add appropriate amount of wine tail, stir evenly, let the water content reach 43%, lay it at a position 12cm higher than the upper surface of the yellow water pit, and set aside;

[0054] S2, preparation of fermentation raw materials: according to a certain ratio, prepare sorghum, wheat and bran of a certain weight ratio, the number of petals broken into sorghum and wheat is 8 petals, and avoid producing fine powder, the sorghum, wheat and bran are fully Mix well;

[0055] S3. Preparation of mixed koji powder: according to a certa...

Embodiment 3

[0071] see figure 1 , the present invention provides a kind of technical scheme: a kind of brewing process of sesame sauce compound wine, comprises the following steps:

[0072] S1. Making cellar pools: Add an insulation layer to the pool wall first, then build it with red bricks, fill the joints with yellow mud between the bricks, and lay a layer of 18cm deep yellow clay on the bottom of the pool. After laying, add high-temperature Daqu Powder 50kg, add appropriate amount of wine tail, stir evenly, let the water content reach 42%, lay it at a position 11cm higher than the upper surface of the yellow water pit, and set aside;

[0073] S2, preparation of fermentation raw materials: according to a certain ratio, prepare sorghum, wheat and bran of a certain weight ratio, the number of petals that sorghum and wheat are broken into is 6 petals, and avoid producing fine powder, fully mix sorghum, wheat and bran Mix well;

[0074] S3. Preparation of mixed koji powder: according to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com