Charge-controllable polymer material as well as preparation method and application thereof

A technology of polymer materials and charges, which is applied in the direction of non-active ingredient medical preparations, medical preparations containing active ingredients, drug combinations, etc., can solve the problems of low immunogenicity, hindering clinical transformation, cytotoxicity, etc., and achieve Excellent biocompatibility, prolonged circulation time, and reduced toxic and side effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Investigate the ability of polymer materials to form coatings on the surface of different materials.

[0047] The polymer material coating of this embodiment is prepared by the following method:

[0048] Mix absolute ethanol, ammonia water, and deionized water at a ratio of 0.5:0.03:1, add Tween 80 solution (final concentration: 10 mM) and stir evenly. Disperse the pre-prepared macroscopic materials glass, plastic, tin foil, or microscopic materials Au NPs, ZnONPs and MSN NPs in the above mixed system, and then add DA and 5-HT in the ratio of 2:3 to the above reaction system in sequence, room temperature Stir in the dark for 24h, then stop stirring. After removing the supernatant, the precipitate was washed 3 times with deionized water to form a PDH coating on the surface of the material.

experiment example

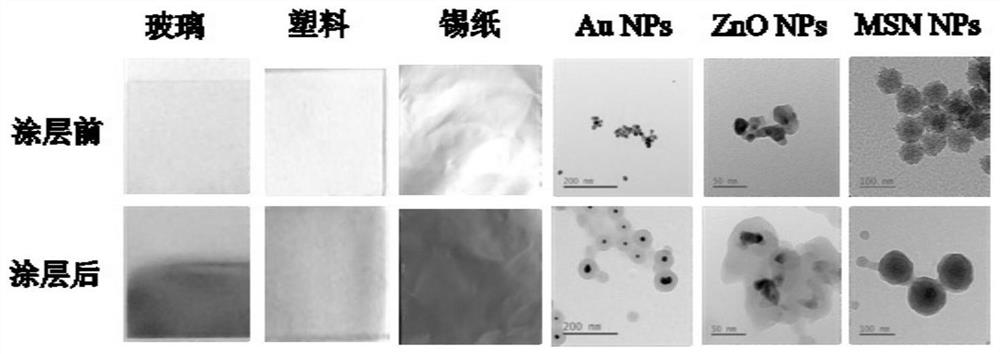

[0050]1. Appearance of macroscopic materials: photographic records of macroscopic materials such as glass, plastic, and tin foil before and after coating with polymer materials. figure 1 Appearance of PDH coating formed on the surface of glass, plastic and tinfoil. It can be seen from the figure that the PDH prepared by the present invention can form a coating on the surface of macroscopic materials such as glass, plastic, and tin foil.

[0051] 2. Microscopic material morphology: observe the morphological changes of Au NPs, ZnO NPs, and MSN NPs before and after coating with PDH. The detection method of the morphology: the sample is dropped on a 400-mesh copper grid covered with a carbon film, placed in a desiccator, and waited for After natural drying, observe under a transmission electron microscope Titan G2-F20. figure 1 It is a transmission electron microscope image of Au, Au / PDH; ZnO, ZnO / PDH; MSN, MSN / PDH NPs. It can be seen from the figure that the PDH prepared by the ...

Embodiment 2

[0054] The PDH coating self-aggregated to form NPs.

[0055] The polymer nanoparticles of this embodiment are prepared by the following method:

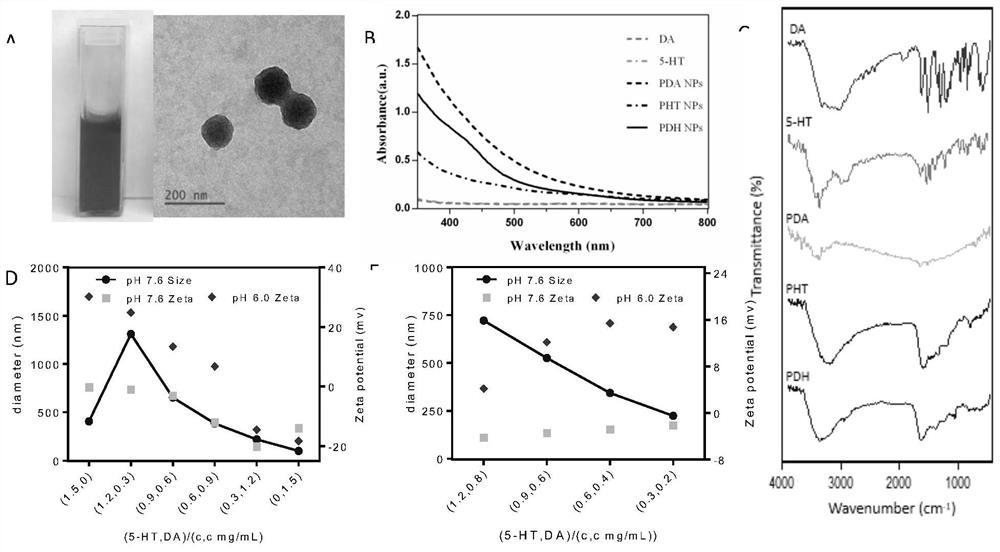

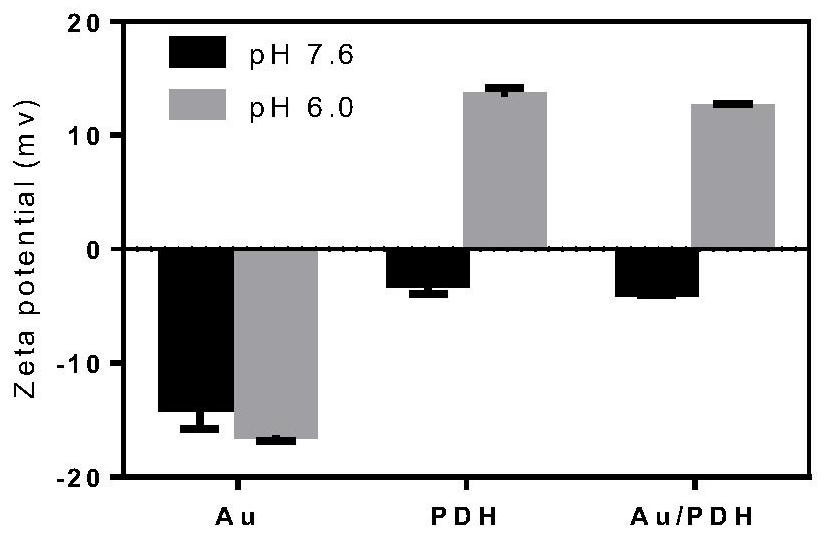

[0056] Mix absolute ethanol, ammonia water, and deionized water at a ratio of 0.5:0.03:1, add Tween 80 solution (final concentration is 10mM) and stir evenly; mix different ratios (5-HT:DA 5:0, 4 :1, 3:2, 2:3, 1:4, 0:5, the total monomer concentration is 1.5mg〃mL -1 ) of DA and 5-HT hydrochloride solution were added to the above reaction system, and stirred at room temperature in the dark for 24 hours until the color deepened (such as figure 2 A), stop stirring; centrifuge at 20000rpm for 30min to remove the supernatant, and wash the precipitate with deionized water for 3 times to obtain PDH NPs; characterize the particle size and potential of NPs in different pH environments, and select a suitable 5-HT :DA ratio to further investigate the correlation between the particle size potential of NPs and the total concentration of monome...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com