Functional 3D printing photosensitive resin and preparation method thereof

A 3D printing and photosensitive resin technology, applied in the direction of additive processing, etc., can solve the problems of material performance limitations and insufficient application scenarios, and achieve the effect of changing physical and chemical properties, wide application scenarios, and fast leveling speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] Another aspect of the present invention provides the preparation method of the functional 3D printing photosensitive resin, comprising the following steps:

[0033] Step A: adding the acrylate resin, acrylate monomer, leveling agent, dyestuff of formula quantity, functional nanoparticles to obtain the primary mixture;

[0034] Step B: heating and stirring the primary mixture, then adding a free radical initiator, an ultraviolet absorber, and a small molecule alcohol, and reacting to obtain the 3D printing photosensitive resin.

[0035] Specifically, the formula in step A follows the formula of the functional 3D printing photosensitive resin.

[0036] In the specific step B, the heating temperature is 40°C-50°C; the reaction at low temperature will be slower, and the temperature will be uncontrollable at high temperature, so the temperature needs to be limited to this range.

[0037] Specifically in the step B, the stirring speed is 800-1000 rpm, and the stirring time i...

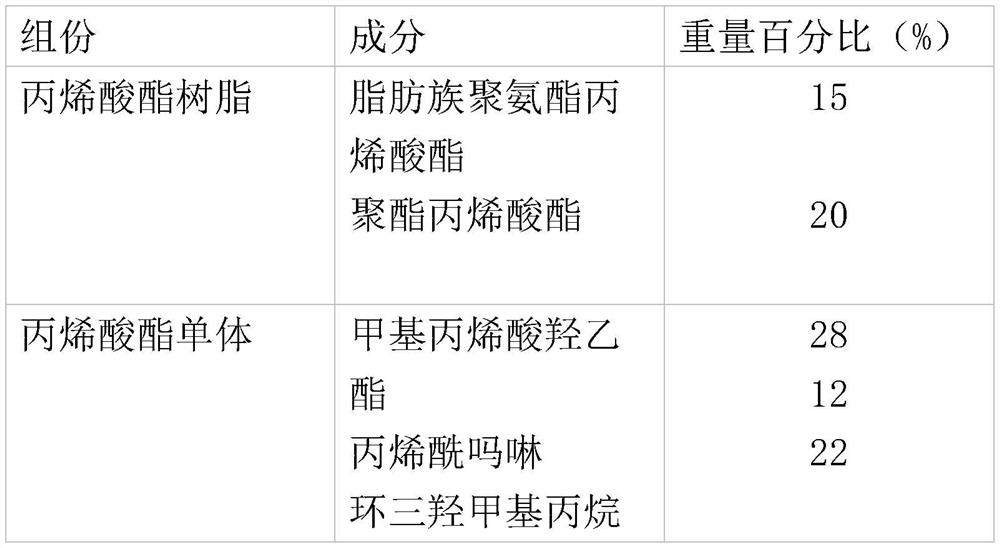

Embodiment 1

[0042] 1. Prepare photosensitive resin raw materials according to the ratio in Table 1

[0043] Table 1

[0044]

[0045]

[0046] 2. Preparation method

[0047] Step A: Add 15 parts of aliphatic urethane acrylate, 20 parts of polyester acrylate, 28 parts of hydroxyethyl methacrylate, 12 parts of acryloyl morpholine, cyclic 22 parts of trimethylolpropane formal acrylate, 10.5 parts of DC5, 0.2 part of oil-soluble black, 0.1 part of ethylene glycol, and 2 parts of carbon nanoparticles to obtain the first mixture.

[0048] Step B: Heat the first mixture obtained in step A to 40°C, adjust the speed of the agitator to 800 rpm, add 2 parts of TPO and 0.3 part of TINUVIN 400, and continue to stir evenly for 1 hour to obtain a light yellow uniform liquid, which is sealed and stored .

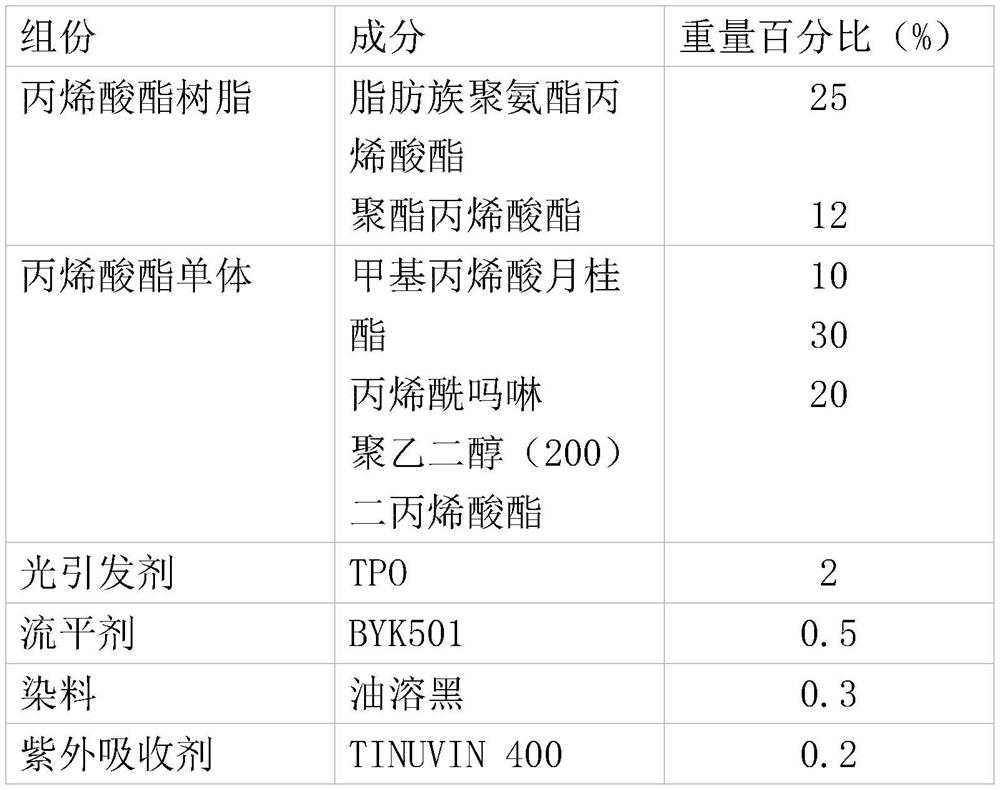

Embodiment 2

[0050] 1. Prepare photosensitive resin raw materials according to the ratio in Table 2

[0051] Table 2

[0052]

[0053]

[0054] 2. Preparation method

[0055] Step A: Add 25 parts of aliphatic urethane acrylate, 12 parts of polyester acrylate, 10 parts of lauryl methacrylate, 30 parts of acryloyl morpholine, polyethylene 20 parts of diol (200) diacrylate, 0.5 parts of BYK501, 0.3 parts of oil-soluble black, 0.2 parts of propylene glycol, and 3 parts of silica nanoparticles to obtain the first mixture.

[0056] Step B: Heat the first mixture obtained in Step A to 40°C, adjust the speed of the agitator to 800 rpm, add 2 parts of TPO and 0.2 parts of TINUVIN 400, and continue to stir evenly for 1 hour to obtain a light yellow uniform liquid, which is sealed and stored .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com