A method for active discharge control of motor windings based on DC voltage feedback control

A feedback control, motor winding technology, applied in motors, electric vehicles, electrical devices, etc., can solve the problems of severe capacitor voltage fluctuations, jumping rises, and unsatisfactory voltage response, to improve safety and voltage pumping. inhibiting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in detail below with reference to the accompanying drawings and specific embodiments. This embodiment is implemented on the premise of the technical solution of the present invention, and provides a detailed implementation manner and a specific operation process, but the protection scope of the present invention is not limited to the following embodiments.

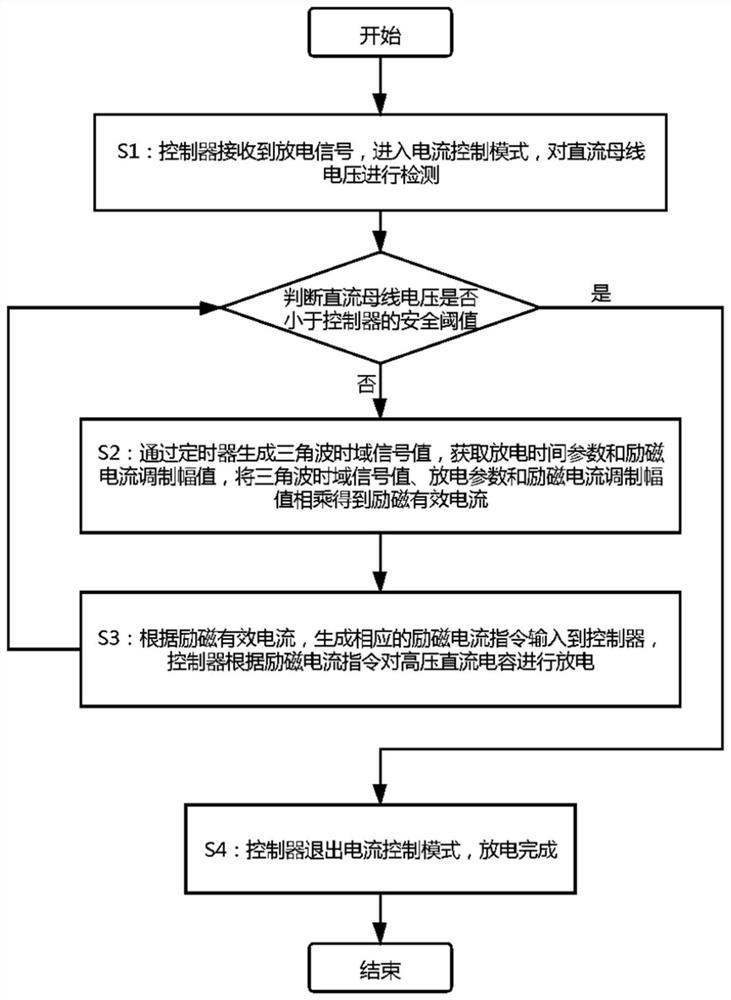

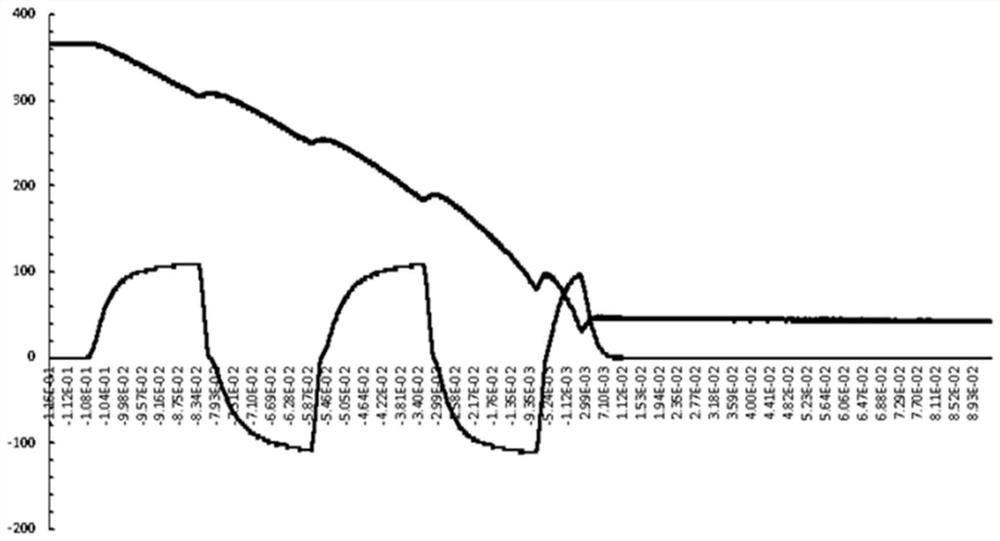

[0034] like figure 2 As shown in the figure, an active discharge control method of a motor winding based on DC voltage feedback control, the discharge is controllable, and there is no danger of voltage jump during the inverter process, which specifically includes the following steps:

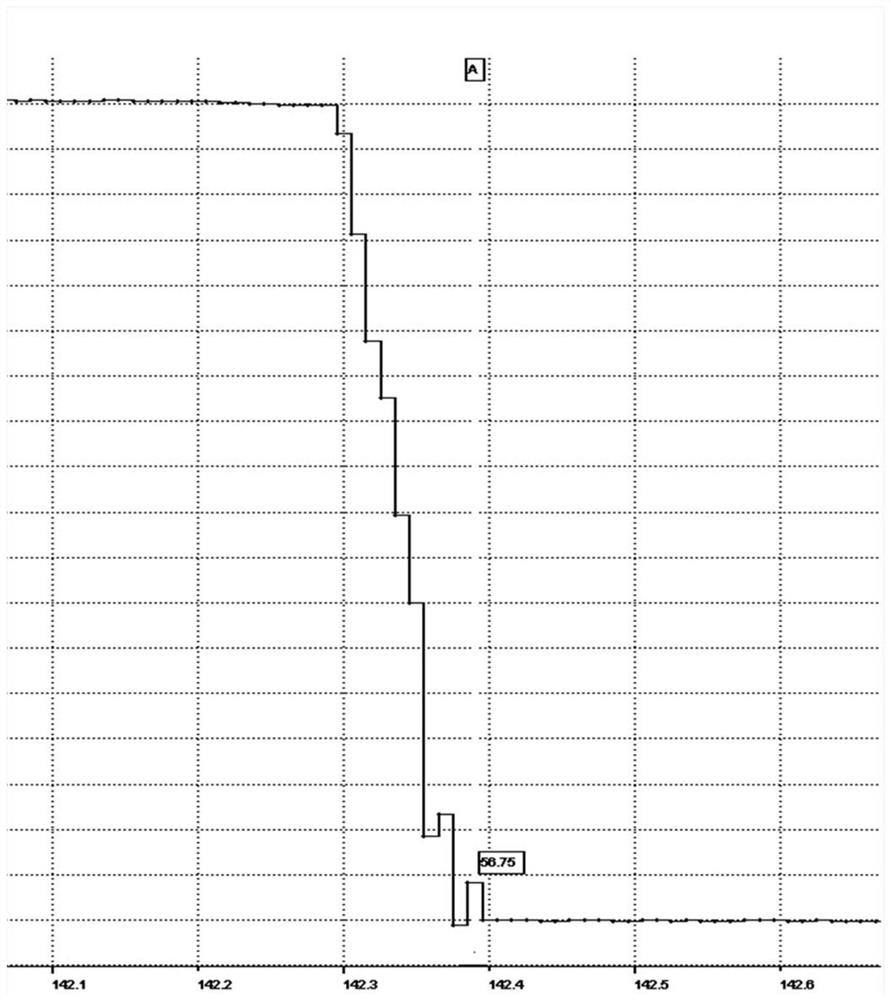

[0035] Step S1: the controller receives the discharge signal, enters the current control mode, and detects the DC bus voltage. If the DC bus voltage is less than the safety threshold of the controller, go to step S4, otherwise go to step S2;

[0036] Step S2: generating the triangular wave tim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com