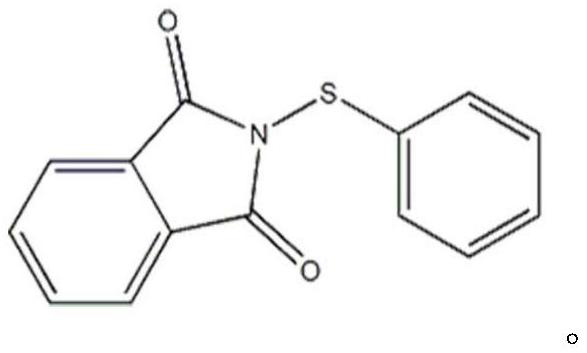

Application of n-(phenylthio)phthalimide in reducing wheat toxin content

A kind of phthalimide, phenylthio-based technology, applied in the field of wheat B-type trichothecenes toxin prevention and control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

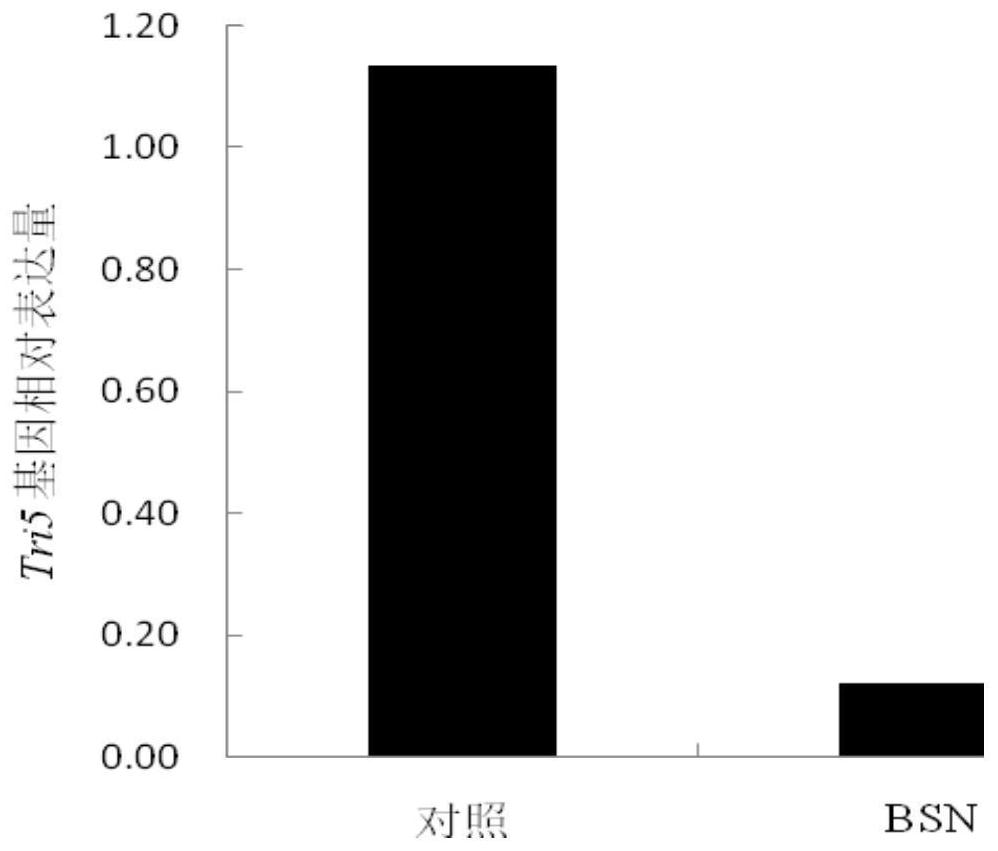

Problems solved by technology

Method used

Image

Examples

preparation Embodiment 1

[0093] Preparation of 20% N-(phenylthio)phthalimide WP:

[0094] In terms of mass percentage, the distribution ratio of each component of the wettable powder is: 20% N-(phenylthio) phthalimide, 5% sodium lignosulfonate (dispersant), 5% pull-off powder (moisturizer) Wet agent), 0.3% penetrant T (penetrant), 0.2% ethylene glycol (stabilizer), 0.5% calcium carbonate (stabilizer), kaolin (filler) to make up 100%.

[0095] Preparation:

[0096] Prepare raw materials according to the above-mentioned proportions, and prepare 20% N-(phenylthio)phthalimide WP through conventional wettable powder processing and preparation methods.

preparation Embodiment 2

[0098] Preparation of 30% N-(phenylthio)phthalimide WG:

[0099] In terms of mass percentage, the distribution ratio of each component of the water dispersible granule is: 30% N-(phenylthio) phthalimide, 8% sodium lauryl sulfate (wetting agent), 8% polyethylene Alcohol (dispersant), 1% fatty alcohol polyoxyethylene ether (penetrant), 1% polyvinyl alcohol (stabilizer), 0.5% calcium carbonate (stabilizer), talcum powder (filler) to make up 100%.

[0100] Preparation:

[0101] Prepare raw materials according to the above-mentioned proportions and process and prepare 30% N-(phenylthio)phthalimide WG through conventional water-dispersible granule processing and preparation methods.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com