Recombinant corynebacterium crenatum capable of producing agmatine, and application thereof

A technology of Corynebacterium bluff and agmatine, applied in the biological field, can solve the problems of hindering the industrialization process of agmatine and high cost, and achieve the effects of low cost, few by-products and high output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

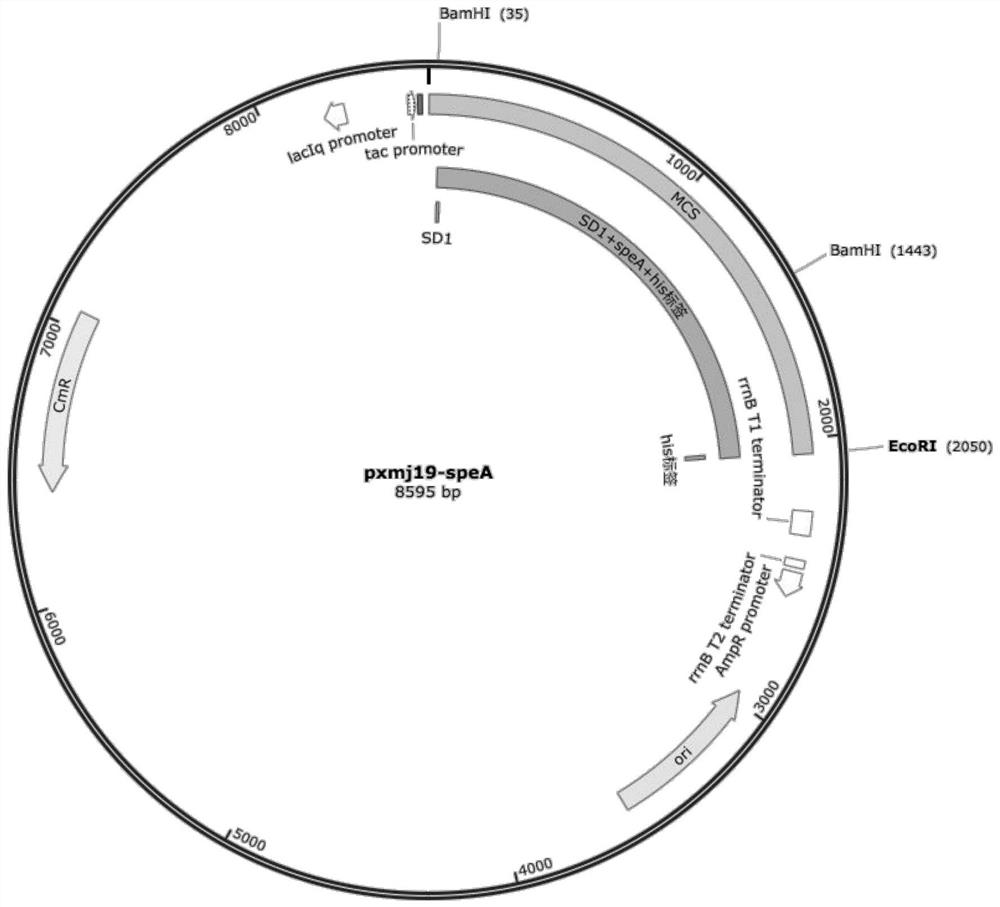

[0035] Embodiment 1: Construction of recombinant Corynebacterium blunt tooth

[0036] Specific steps are as follows:

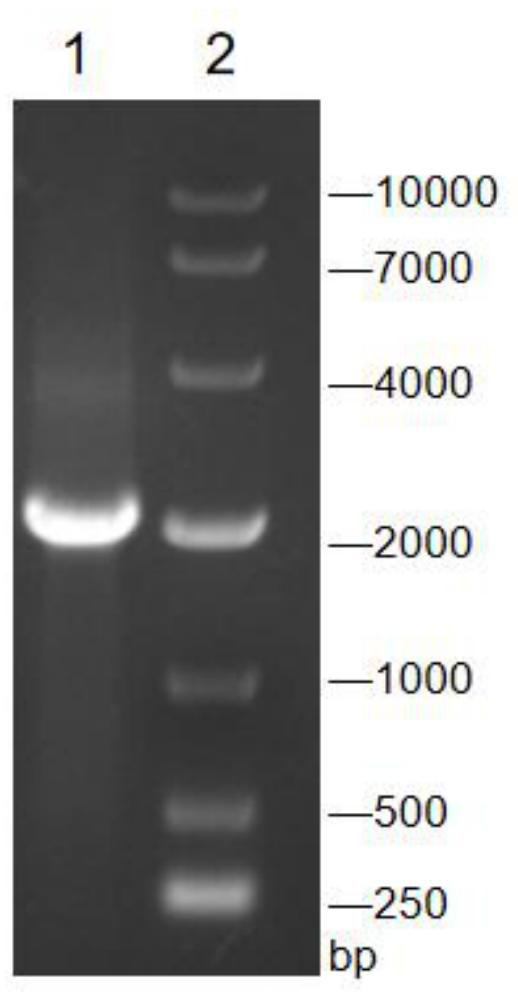

[0037] (1) Use the genome of Escherichia coli (Escherichia coli) BL21 as a template, and use F and R as primers to carry out PCR amplification to obtain the gene speA encoding arginine decarboxylase as shown in SEQ ID No.2. ;

[0038] Wherein, the PCR amplification primers are:

[0039] F: 5'-ggtcgactctagaggatccAAAGGAGGAAAATCatgtctgacgacatgtctatg-3' (BamHI) (SEQ ID No. 3);

[0040] R: 5'-gccaaaacagccaagctgaattcttaGTGGTGGTGGTGGTGGTGctcatcttcaagataagtataaccgtacaaacctgcctcg-3' (EcoR 1) (SEQ ID No. 4);

[0041] PCR amplification conditions are: 95°C pre-denaturation, 5min; 95°C denaturation, 30s, 55°C annealing, 30s, 72°C extension, 90s, 30 cycles; 72°C final extension 5min;

[0042] The PCR amplification system is: template 1 μL, upstream and downstream primers 1 μL, sterilized double distilled water 22 μL, 2×Phanta MaxMaster Mix 25 μL.

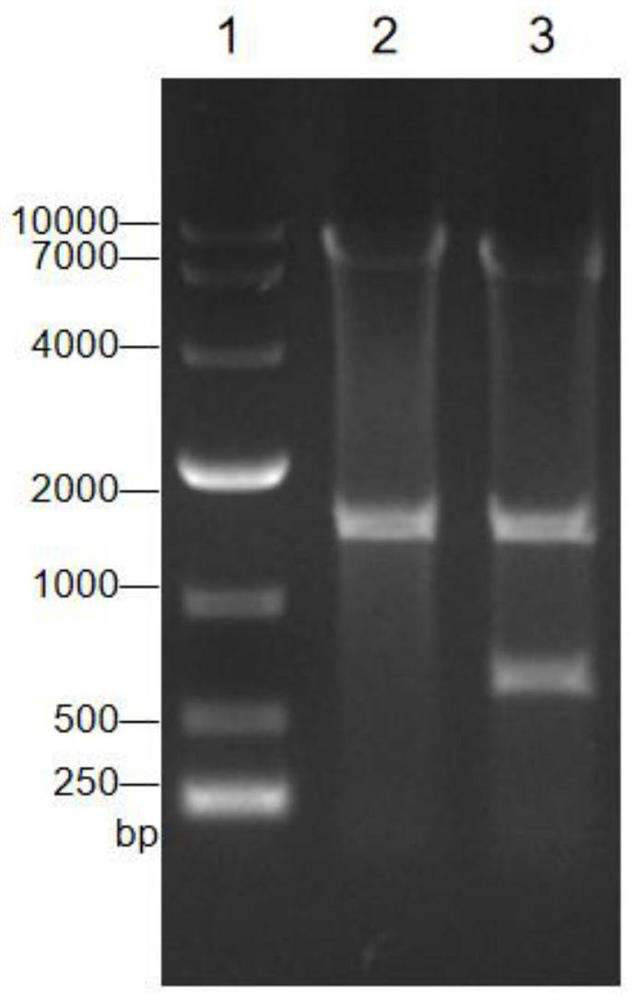

[0043] (2) the gene...

Embodiment 2

[0045] Embodiment 2: the production of agmatine (whole cell transformation method)

[0046] Specific steps are as follows:

[0047] (1) With Corynebacterium crenatum SYPA5-5 as a control, a single colony of Corynebacterium crenatum SYPA5-5 was picked and inoculated into BHI liquid medium, and the recombinant blunt bacteria obtained in Example 1 A single colony of C. crenatum SYPA5-5 / pXMJ19-speA was inoculated to contain 10 μg·mL -1 In the BHI liquid medium of chloramphenicol, the temperature was 30°C and the rotation speed was 180rpm, and the shaker was cultured for 24 hours to obtain seed solutions 1-2; the seed solution 1 was inoculated with 2% (v / v) inoculum Into the BHI liquid medium, inoculate the seed liquid 2 with a 2% (v / v) inoculation amount to contain 10 μg·mL -1 In the BHI liquid medium of chloramphenicol, cultured on a shaker at a temperature of 30°C and a rotation speed of 180rpm for 10h, then added IPTG with a final concentration of 0.1mM to the culture medium,...

Embodiment 3

[0050] Embodiment 3: the production of agmatine (biological fermentation method+shaking flask)

[0051] Specific steps are as follows:

[0052] A single colony of the recombinant Corynebacterium crenatum SYPA5-5 / pXMJ19-speA obtained in Example 1 was picked and inoculated into the seed medium, and cultured on a shaker at a temperature of 30°C and a rotation speed of 180rpm for 24h to obtain Seed liquid: inoculate the seed liquid into the fermentation medium with a 10% (v / v) inoculum amount, and after cultivating on a shaker at a temperature of 30°C and a rotation speed of 220rpm for 24h, add a final concentration of 0.1 to the medium. mM IPTG was used to induce fermentation for 72 hours at a temperature of 30° C. and a rotation speed of 220 rpm to obtain a fermentation broth.

[0053] Detect the contents of L-arginine and agmatine in the fermentation broth, and the test results are: the content of agmatine in the fermentation broth obtained by C.crenatum SYPA5-5 / pXMJ19-speA fe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com