Combined inhibitor for zinc sulfide ore and application thereof

A combination inhibitor and zinc sulfide ore technology, applied in chemical instruments and methods, magnetic separation, solid separation, etc., can solve the problems of high zinc content, low recovery rate of zinc metal, large dosage of chemicals, etc., to achieve low risk and low investment The effect of small size and low drug cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

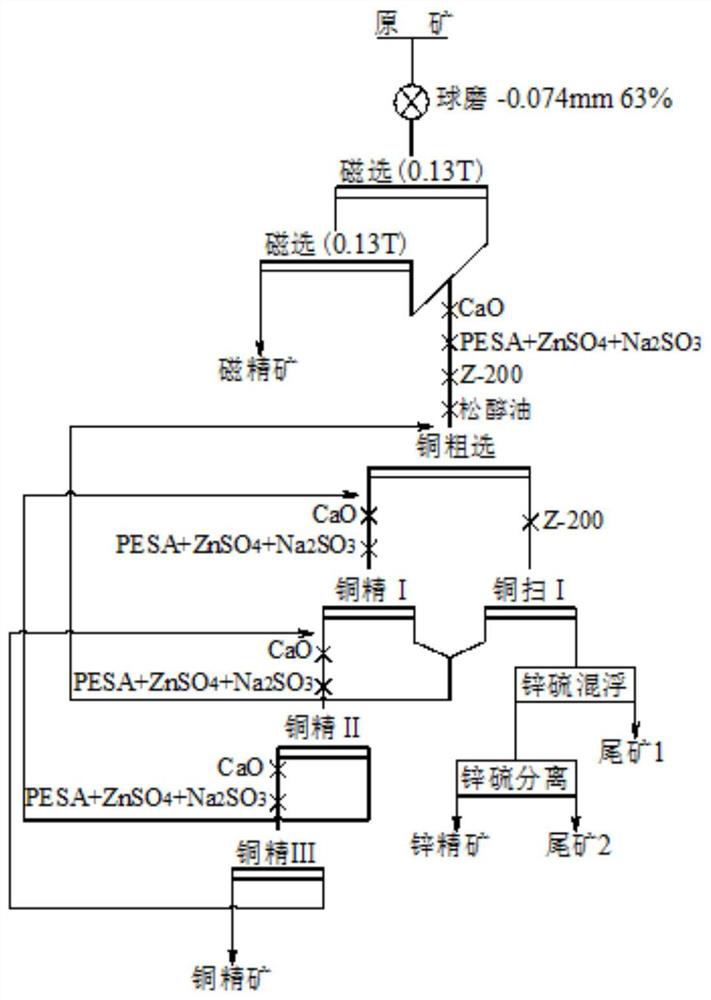

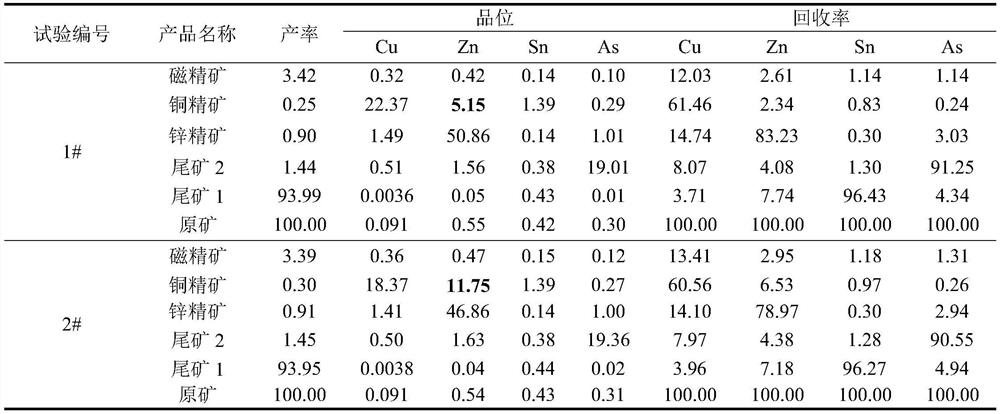

[0024] A tin-copper-zinc polymetallic mine in Yunnan, the grade of tin in the ore is 0.42%, the grade of copper is 0.090%, and the grade of zinc is 0.53%. %. Phase analysis shows that copper and zinc in the ore mainly exist in the form of primary copper sulfide and zinc sulfide. The mineral composition of the mine is relatively complex. The metal minerals are mainly cassiterite, chalcopyrite and pyrrhotite, followed by arsenopyrite, sphalerite and a small amount of pyrite. Gangue minerals are mainly quartz, mica, feldspar, oblique zoisite and so on. Useful minerals are interbedded with medium and fine grains, and the intercalation relationship between minerals is extremely complicated. Chalcopyrite aggregates are rarely seen, mostly disseminated or fine-grained, while sphalerite is mostly wrapped with fine grains and microfine grains. Chalcopyrite. The raw ore contains a certain amount of mica and screen stone minerals, which have good buoyancy, seriously interfere with the...

Embodiment 2

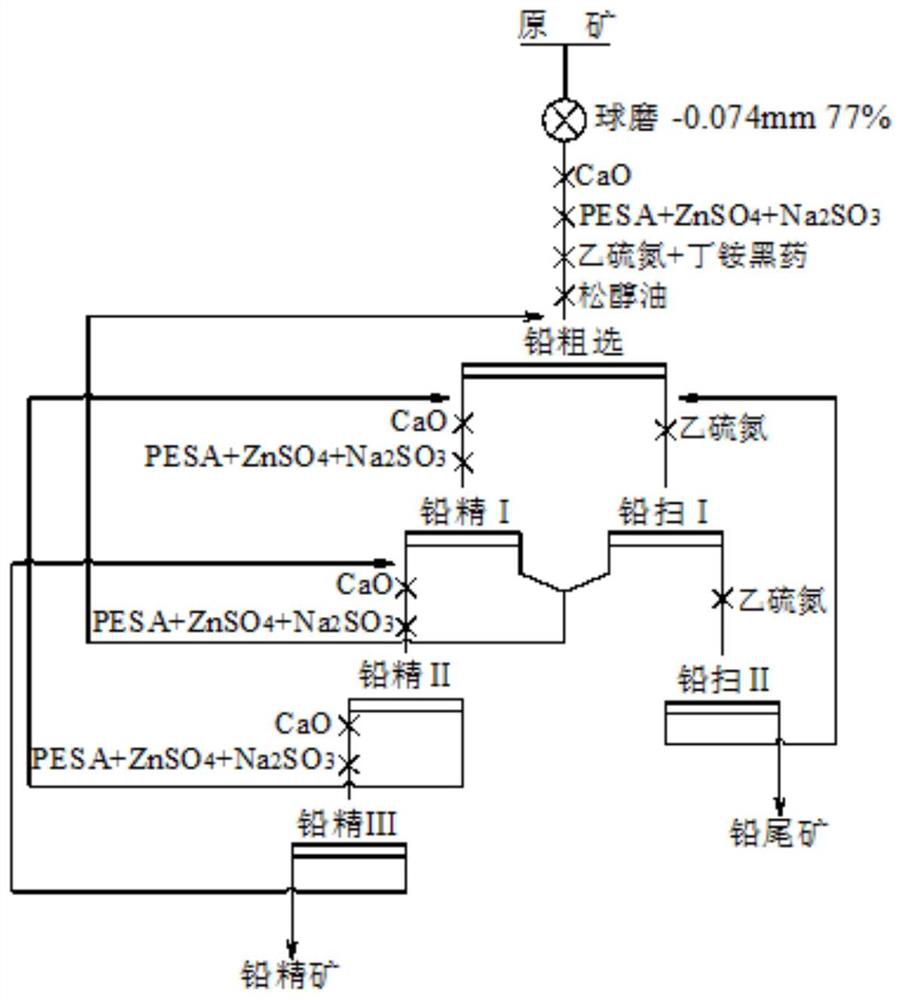

[0044] In a silver-lead-zinc polymetallic sulfide mine in Sichuan, the main valuable metals available for recovery in the raw ore are silver, lead, and zinc, with grades of 60.12g / t, 1.31% and 5.44%, respectively, and the grade ratio of lead and zinc is 1: 4.2, containing 5.31% sulfur. The mineral composition is complex, the intercalation relationship is close, and the useful minerals are in medium and fine distribution. The main metal minerals are galena, sphalerite, pyrite, trace chalcopyrite, and the main gangue minerals are calcite, quartz barite and sericite. According to the phase analysis, lead mainly occurs in galena (92.04%), zinc mainly occurs in sphalerite (96.54%); silver mainly occurs in sulfide (51.59%) ), followed by silver, silver sulfide and elemental silver in silicate.

[0045] The inhibitory effect of the combined inhibitor on sphalerite in the lead priority flotation operation, the test process and the reagent system are as follows: figure 2 , the flot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com