A corrosion-resistant aluminum alloy profile

A corrosion-resistant aluminum alloy and aluminum alloy technology, applied in metal material coating process, coating, melt spraying and other directions, can solve the problems of difficult to apply corrosion phenomenon, restrict the wide application of aluminum alloy profiles, etc., to enhance the impact resistance effect , avoid staggered, improve the effect of corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

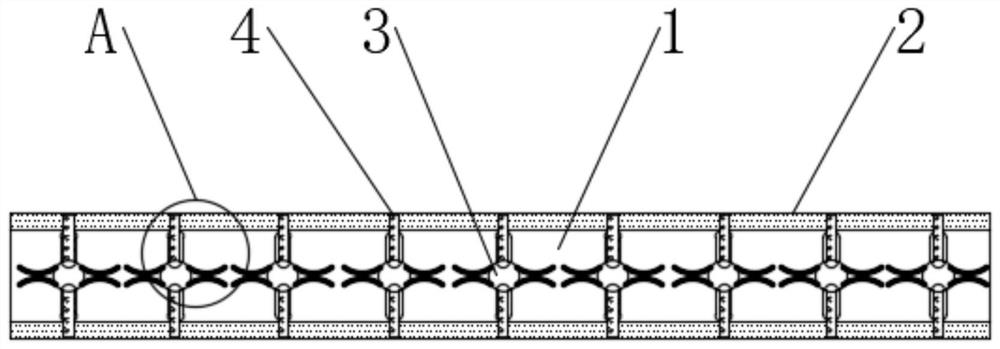

[0044] see Figure 1-3 , a corrosion-resistant aluminum alloy profile, comprising an aluminum alloy base body 1 and a nano-ceramic coating 2 covering the outer surface of the aluminum alloy base body 1, the aluminum alloy base body 1 is inlaid and connected with a plurality of evenly distributed embedded repair rods 3, The built-in repair rod 3 includes an alumina hollow repair ball 31 and an alumina hollow bollard 32 symmetrically connected to the upper and lower ends of the alumina hollow repair ball 31, and the alumina hollow repair ball 31 and the alumina hollow bollard 32 are integrally connected, and oxidized. The upper and lower ends of the aluminum hollow repair ball 31 are inlaid and connected with a fast corrosion isolation layer 33, and the alumina hollow bollard 32 is inlaid and connected with a fast corrosion mandrel 4, and the fast corrosion mandrel 4 penetrates the aluminum alloy base 1 and extends to the nano-ceramic in coating 2.

[0045] The cross-sectional ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com