Method for taking out heat-treated bar for manufacturing copper-clad aluminum busbar cable

A technology of copper-clad aluminum bars and copper-clad aluminum, applied in heat treatment furnaces, heat treatment equipment, manufacturing tools, etc., can solve problems such as restricting development and increasing production costs, and achieve the effect of preventing the loss of heat and nitrogen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

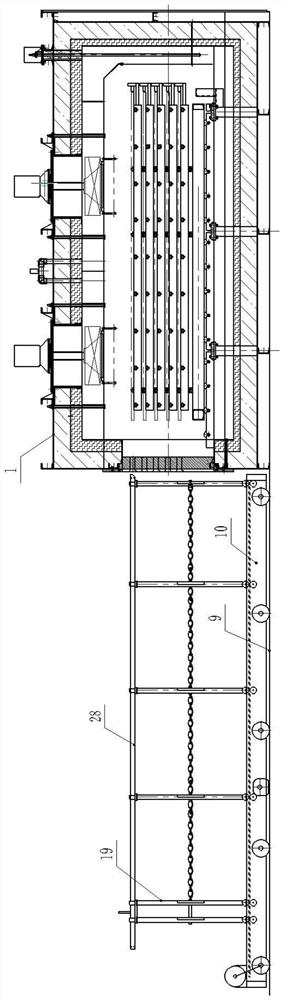

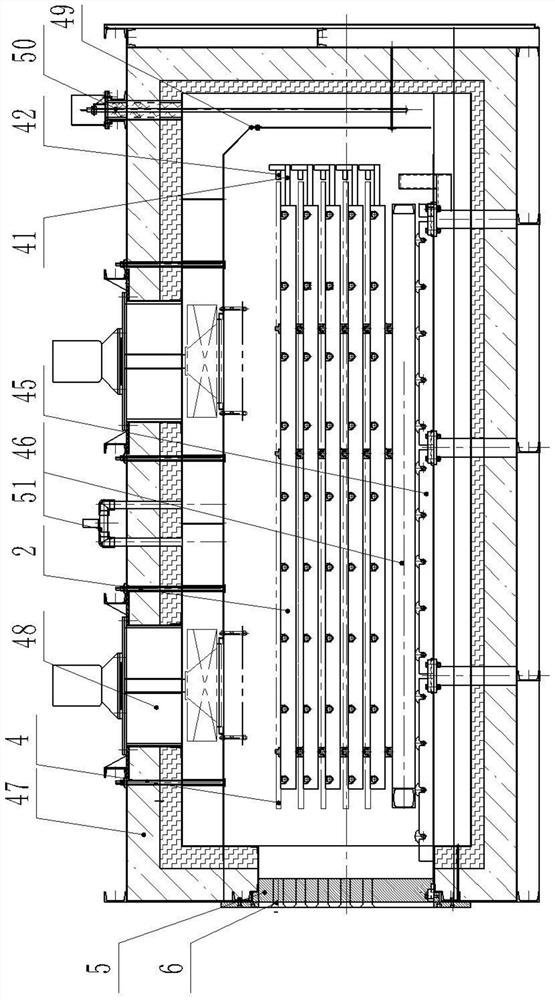

[0039] Such as Figure 1-8 Shown, the present invention 1, make the method for taking out after the bar stock heat treatment of copper-clad aluminum row cable, comprise steps:

[0040] Step 1. A multi-layer copper-clad aluminum bar rack 2 is provided in the nitrogen-protected heating box furnace 1, and a plurality of bar stock stations 3 are arranged on each layer of copper-clad aluminum bar stock rack 1, and each bar stock station 3 corresponds to place a copper-clad aluminum rod 4; the nitrogen-protected heating box furnace 1 is provided with a lifting furnace door 5, and when the lifting furnace door 5 is closed, each copper-clad aluminum rod 4 corresponds to a lifting furnace door 5 is provided with a bar material take-out port 6, and each bar stock take-out port 6 is provided with a sealing plug 7;

[0041] Step 2, a guide rail 9 is provided on the ground corresponding to the furnace door 8 of the nitrogen-protected heating box furnace 1, and an electric cart 10 is provi...

Embodiment 2

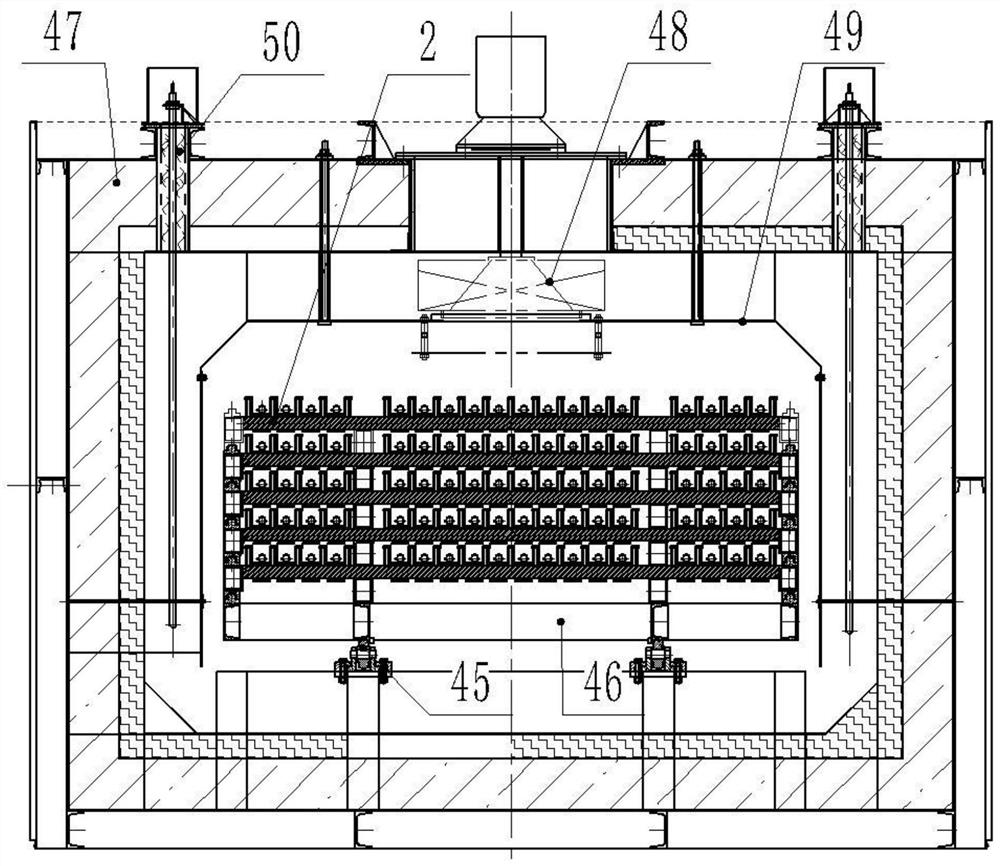

[0054] Such as Figure 1-8As shown, the present invention is made into a copper-clad aluminum row cable bar material heat treatment method for taking out, the copper-clad aluminum bar rack 2 includes a side support frame 33, a horizontal support frame 34 and a vertical support frame 35, two side support frames 33 are connected by a plurality of cross braces 34, and a plurality of cross braces 34 are connected in series through more than one vertical brace 35. A protruding butt joint 36 is provided on the top surface of the side support frame 33, and on the bottom surface of the side support frame 33 A concave butt joint 37 is provided. The concave butt joint 37 of each layer of copper-clad aluminum bar stock rack 2 is butted on the raised butt joint 36 of the lower layer of copper-clad aluminum bar stock rack 2 to be superimposed.

[0055] A plurality of bar stock stations 3 are arranged on the cross brace 34, and the bar stock stations 3 on each cross brace 34 are correspond...

Embodiment 3

[0059] Such as Figure 1-8 As shown, the present invention is made into a copper-clad aluminum row cable rod stock heat treatment method for taking out, the fetching pipe 28 is a square pipe, and the fetching pipe 28 can be a square pipe or a round pipe, and the square pipe is better to use. The lower side of the front end of the retrieving pipe 28 is provided with a wedge-shaped surface. When the retrieving pipe 28 enters and exits the furnace from the bar stock outlet 6, the copper-clad aluminum bar 4 is basically in the center of the retrieving pipe 28, so when the retrieving Pipe 28 stretches out in the hearth constantly, and the front end of material fetching pipe 28 will be against on the cross brace 34 of copper-clad aluminum rod rack 2, by being provided with wedge-shaped surface under the front end of taking material pipe 28, so just can The pick tube 28 is slid into the cross brace 34 .

[0060] The method for taking out the bar material of the copper-clad aluminum ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com