Colorful paint and spraying method thereof

A technology of magic color and paint, applied in the field of magic color paint and its spraying, which can solve the problems of easy yellowing, weak adhesion, washing with alcohol, detergent and water, etc., to achieve simple processing and improve visual perception , The effect of simple processing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

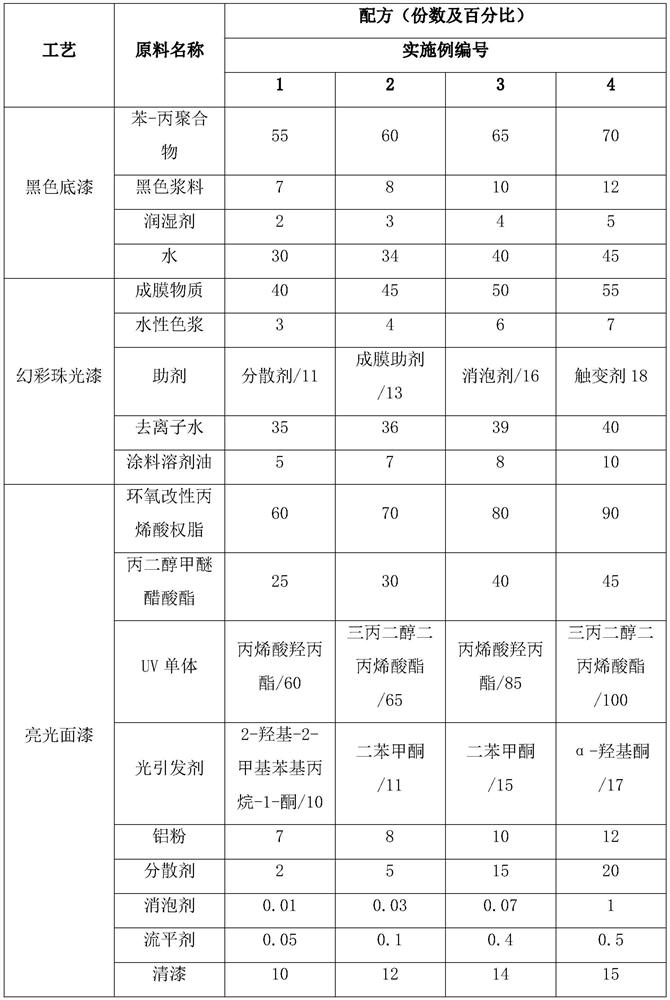

Embodiment 1

[0045] The illusion paint that present embodiment provides is:

[0046] The black primer is mixed by the following raw material components and their parts by weight: 55 parts of styrene-acrylic polymer, 7 parts of black slurry, 2 parts of wetting agent, and 30 parts of water;

[0047] The magic color pearlescent paint comprises components and the mass percentages of components are: 40% of film-forming substance, 3% of water-based color paste, 11% of dispersant, 35% of deionized water, and 5% of solvent oil for paint;

[0048] The bright finish paint is made by mixing the following raw material components and their parts by weight: 60 parts of epoxy modified acrylate, 25 parts of propylene glycol methyl ether acetate, 60 parts of hydroxypropyl acrylate, 2-hydroxy-2-methylbenzene 10 parts of propane-1-one, 7 parts of aluminum powder, 2 parts of dispersant, 0.01 part of defoamer, 0.05 part of leveling agent, and 10 parts of varnish.

[0049] The spraying method of its illusion p...

Embodiment 2

[0056] The illusion paint that present embodiment provides is:

[0057] The black primer is mixed by the following raw material components and parts by weight: 60 parts of styrene-acrylic polymer, 8 parts of black slurry, 3 parts of wetting agent, and 34 parts of water;

[0058] The magic color pearlescent paint comprises components and the mass percentages of components are: 45% of film-forming substance, 4% of water-based color paste, 13% of film-forming aid, 36% of deionized water, and 7% of paint solvent oil;

[0059] The bright finish paint is mixed by the following raw material components and their parts by weight: 70 parts of epoxy modified acrylate, 30 parts of propylene glycol methyl ether acetate, 65 parts of tripropylene glycol diacrylate, 11 parts of benzophenone, aluminum 8 parts of powder, 5 parts of dispersant, 0.03 parts of defoamer, 0.1 part of leveling agent, 12 parts of varnish.

[0060] The spraying method of its illusion paint is identical with embodiment...

Embodiment 3

[0062] The black primer is mixed by the following raw material components and parts by weight thereof: 65 parts of benzene-propylene polymerization, 10 parts of black slurry, 4 parts of wetting agent, 40 parts of water;

[0063] The magic color pearlescent paint comprises components and the mass percentages of components are: 50% film-forming substance, 6% water-based color paste, 16% defoamer, 39% deionized water, and 8% solvent oil for paint;

[0064] The bright finish paint is made by mixing the following raw material components and their parts by weight: 80 parts of epoxy modified acrylate, 40 parts of propylene glycol methyl ether acetate, 85 parts of hydroxypropyl acrylate, 15 parts of benzophenone, aluminum powder 10 parts, dispersant 15 parts, defoamer 0.07 parts, leveling agent 0.4 parts, varnish 14 parts.

[0065] The spraying method of its illusion paint is identical with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com