Green body for high-strength thin ceramic plate, high-strength thin ceramic plate and preparation method thereof

A high-strength, ceramic plate technology, applied in applications, household appliances, clay products, etc., can solve the problem of low mechanical strength of thin ceramic plates, achieve the effect of improving the modulus of rupture and bulk density, and broadening the application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

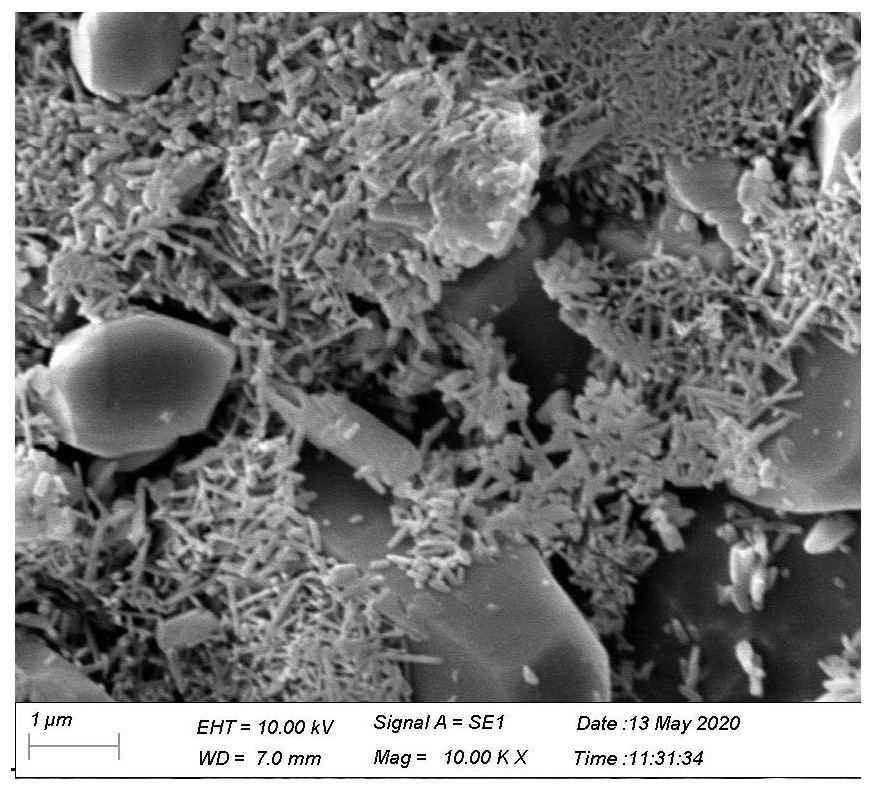

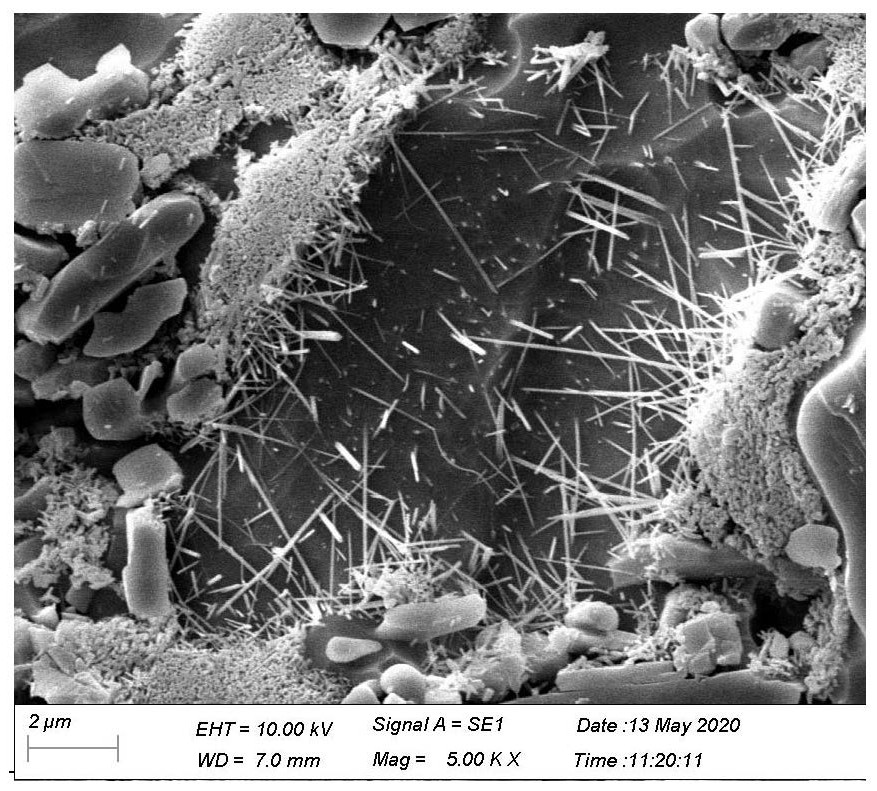

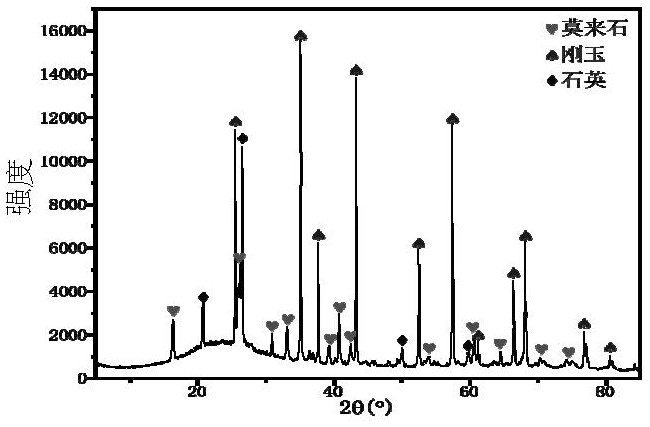

[0048] Step 1: Prepare green body powder according to the proportion. The raw material composition of the green body powder includes: in terms of mass percentage, potassium feldspar 11.0%, albite 5.0%, illite: 20.0%, calcined alumina 31.0%, talc mud: 3.0%, acicular kaolin: 27.0%, bentonite: 3.0%. The chemical composition of the green body powder is: by mass percentage, SiO 2 : 40.24%, Al 2 o 3 : 48.79%, Fe 2 o 3 : 0.37%, TiO 2 : 0.26%, CaO: 0.30%, MgO: 1.02%, K 2 O: 3.09%, Na 2 O: 1.71%, loss on ignition: 4.11%. The mineral composition of the green body after burning is: in terms of mass percentage, glass phase: 39.62%, mullite: 25.72%, corundum: 24.80%, quartz: 9.86% (such as image 3 shown).

[0049] Step 2: pressing and molding the green body powder to obtain bricks. The brick adobe is dried, and the drying time is 15-30 minutes, and the moisture content of the dried adobe is controlled within 0.5wt%.

[0050] Step 3: Use a digital spray glaze machine to apply a...

Embodiment 2

[0058] Step 1: Prepare green body powder according to the proportion. The raw material composition of the green body powder includes: by mass percentage, potassium feldspar 18.0%, albite 2.0%, illite: 16.0%, calcined alumina 28.0%, talc mud: 2.0%, acicular kaolin: 30.0%, bentonite: 4.0%. The chemical composition of the green body powder is: by mass percentage, SiO 2 : 42.52%, Al 2 o 3 : 46.30%, Fe 2 o 3 : 0.39%, TiO 2 : 0.22%, CaO: 0.31%, MgO: 0.77%, K 2 O: 3.56%, Na 2 O: 1.54%, loss on ignition: 4.26%. The mineral composition of the green body after sintering is: in terms of mass percentage, glass phase: 36.38%, mullite: 29.68%, corundum: 22.41%, quartz: 11.53%.

[0059] Step 2: pressing and molding the green body powder to obtain bricks. The brick adobe is dried, and the drying time is 15-30 minutes, and the moisture content of the dried adobe is controlled within 0.5wt%.

[0060] Step 3: Use a digital spray glaze machine to apply a digital surface glaze on the dr...

Embodiment 3

[0068] Step 1: Prepare green body powder according to the proportion. The raw material composition of the green body powder includes: by mass percentage, potassium feldspar 4.0%, albite 8.0%, illite: 24.0%, calcined alumina 34.0%, talc mud: 4.0%, acicular kaolin: 24.0%, bentonite: 2.0%. The chemical composition of the green body powder is: by mass percentage, SiO 2 : 37.97%, Al 2 o 3 : 51.28%, Fe 2 o 3 : 0.35%, TiO 2 : 0.30%, CaO: 0.28%, MgO: 1.27%, K 2 O: 2.62%, Na 2 O: 1.87%, loss on ignition: 3.95%. The mineral composition of the green body after sintering is: in terms of mass percentage, glass phase: 43.68%, mullite: 21.35%, corundum: 26.25%, quartz: 8.72%.

[0069] Step 2: pressing and molding the green body powder to obtain bricks. The brick adobe is dried, and the drying time is 15-30 minutes, and the moisture content of the dried adobe is controlled within 0.5wt%.

[0070] Step 3: Use a digital spray glaze machine to apply a digital surface glaze on the drie...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com