Porcelain archaized brick with golden glittering effect and preparation method of porcelain archaized brick

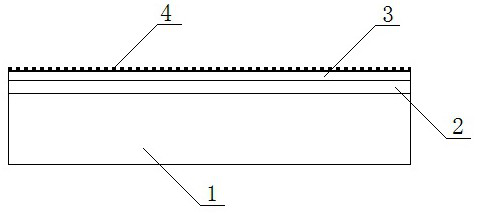

An antique brick and gold technology, applied in the field of porcelain antique brick and its preparation, can solve the problems of not having transparent polishing glaze and flashing gold material fired at one time and completely fused, no three-dimensional sense, not durable, etc. Rich texture expressive, transparent three-dimensional three-dimensional effect, strong three-dimensional effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Example 1 (taking the production of 600*600mm products as an example)

[0042] A porcelain antique brick with golden glitter effect, the golden glitter glaze used in the porcelain antique brick with golden glitter effect is composed of the following raw materials in parts by weight: 880 ink: 45 parts, glitter material A: 40 parts, And flashing material B: 8 parts; the flow rate of the 880 ink is 18 seconds; the 880 ink is composed of the following raw materials in parts by weight: 83 parts of water; 5.0 parts of sodium carboxymethyl cellulose; ethylene glycol: 5 parts; acrylic acid Copolymer: 0.5 parts; Polyurethane: 1 part; Isothiazolinone: 1 part; Sodium polycarboxylate: 2 parts;

[0043] The flashing material A is used to adjust the flashing effect of the golden flashing glaze; the flashing material A includes the following chemical components by weight percentage: loss on ignition: 1.00%; SiO 2 : 0.2%; Al 2 o 3 : 0.01%; CaO: 0.01%; P 2 o 5 : 0.2%; SO 3 : 0.2%;...

Embodiment 2

[0050] Example 2 (taking the production of 600*600mm products as an example)

[0051] A porcelain antique brick with golden glitter effect, the golden glitter glaze used in the porcelain antique brick with golden glitter effect is composed of the following raw materials in parts by weight: 880 ink: 50 parts, glitter material A: 45 parts, And flashing material B: 15 parts; the flow rate of the 880 ink is 25 seconds; the 880 ink is composed of the following raw materials in parts by weight: 86 parts of water; 8.0 parts of sodium carboxymethyl cellulose; ethylene glycol: 8 parts; acrylic acid Copolymer: 1.5 parts; Polyurethane: 2 parts; Isothiazolinone: 2 parts; Sodium polycarboxylate: 3 parts;

[0052] The flashing material A is used to adjust the flashing effect of the golden flashing glaze; the flashing material A includes the following chemical components by weight percentage: loss on ignition: 1.00%; SiO 2 : 0.2%; Al 2 o 3 : 0.01%; CaO: 0.01%; P 2 o 5 : 0.15%; SO 3 : 0...

Embodiment 3

[0059] Example 3 (taking 600*600mm product production as an example)

[0060] A porcelain antique brick with golden glitter effect, the golden glitter glaze used in the porcelain antique brick with golden glitter effect is composed of the following raw materials in parts by weight: 880 ink: 47 parts, glitter material A: 42 parts, And flashing material B: 10 parts; the flow rate of the 880 ink is 22 seconds; the 880 ink is composed of the following raw materials in parts by weight: 84 parts of water; 6.0 parts of sodium carboxymethyl cellulose; ethylene glycol: 6 parts; acrylic acid Copolymer: 0.8 parts; Polyurethane: 1.2 parts; Isothiazolinone: 1.5 parts; Sodium polycarboxylate: 2.5 parts;

[0061] The flashing material A is used to adjust the flashing effect of the golden flashing glaze; the flashing material A includes the following chemical components by weight percentage: loss on ignition: 1.00%; SiO 2 : 0.15%; Al 2 o 3 : 0.01%; CaO: 0.01%; P 2 o 5 : 0.2%; SO 3 : 0.2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com