Plastic particle conveyor

A technology of plastic granules and conveyors, which is applied in the field of conveyors, which can solve the problems of the safety and health of workers, the vulnerability to moisture, and the inefficiency of plastic granules, and achieve the effect of improving the efficiency of dust removal and dehumidification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

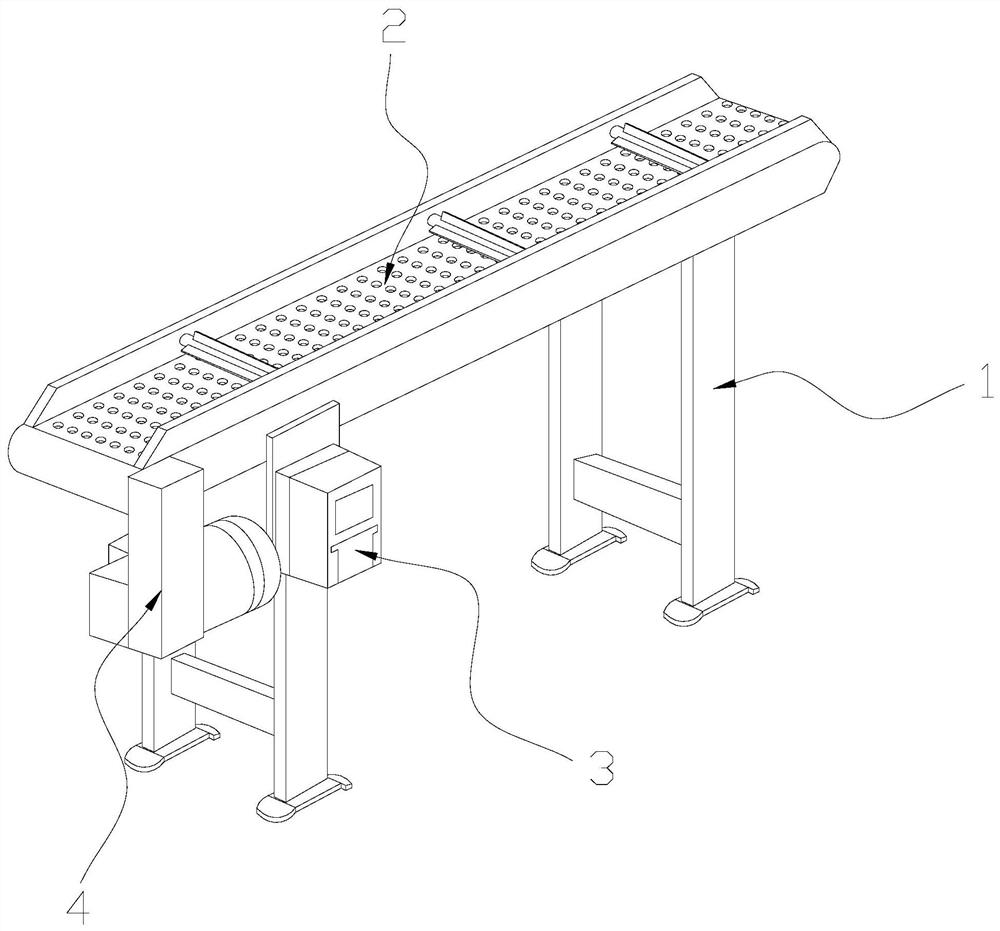

[0028] see Figure 1-Figure 4 , the present invention provides a plastic particle conveyor, the structure of which includes a frame 1, a particle conveyor 2, an electric controller 3, and a driving device 4, the top of the frame 1 is provided with a particle conveyor 2, and the The frame 1 and the particle conveyor 2 are welded by electric welding, the surface of the particle conveyor 2 is provided with a drive device 4, the particle conveyor 2 and the drive device 4 are connected by transmission, and the surface of the frame 1 is installed There is an electric controller 3, and the electric controller 3 is electrically connected to the driving device 4;

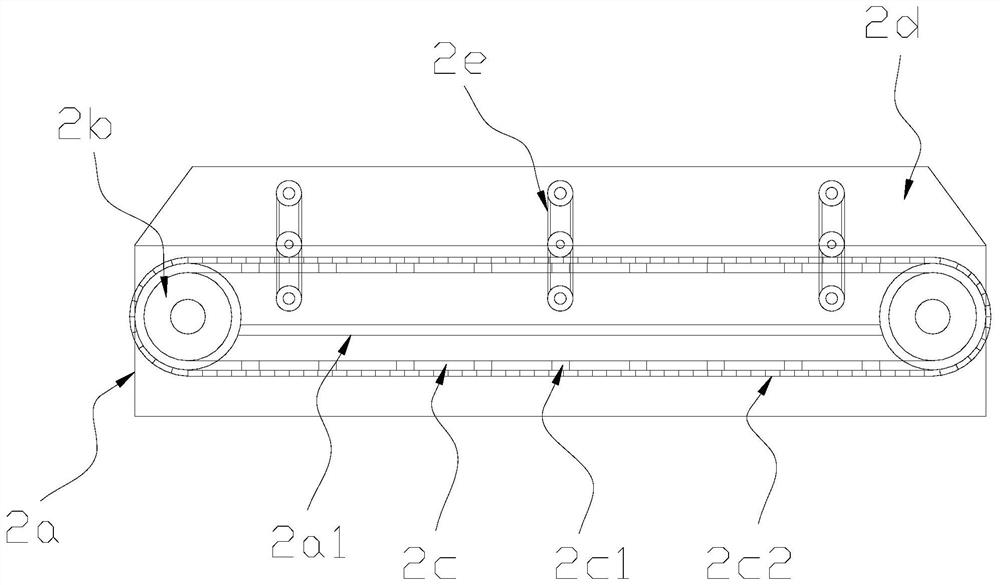

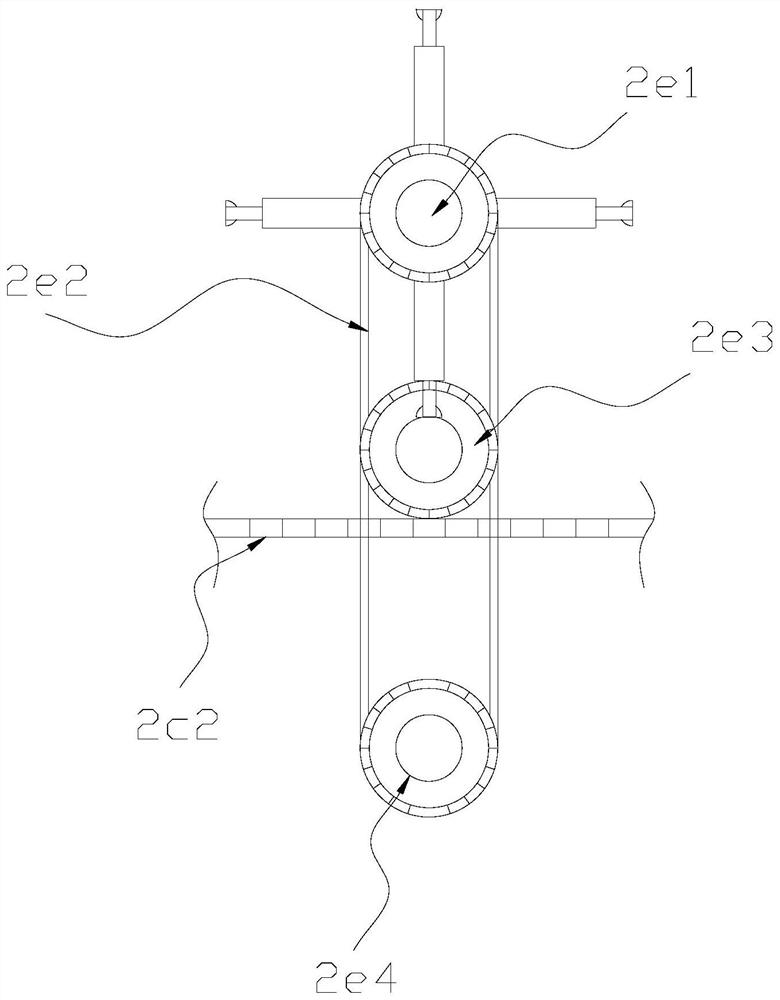

[0029] The particle conveyor 2 is composed of a body 2a, a roller 2b, a conveyor belt 2c, a baffle 2d, and an interlocking stirring device 2e. The top of the body 2a is provided with a baffle 2d, and the body 2a and the baffle 2d are Fixedly connected, two rollers 2b are arranged on the inner side of the body 2a, the body 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com