High-aluminizing-fastness BOPP base film for low-temperature laser mold pressing and preparation method thereof

A molding and laser technology, applied in the direction of chemical instruments and methods, applications, flat products, etc., can solve the problems of low production efficiency, achieve the effect of improving stiffness, improving molding performance, and improving compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

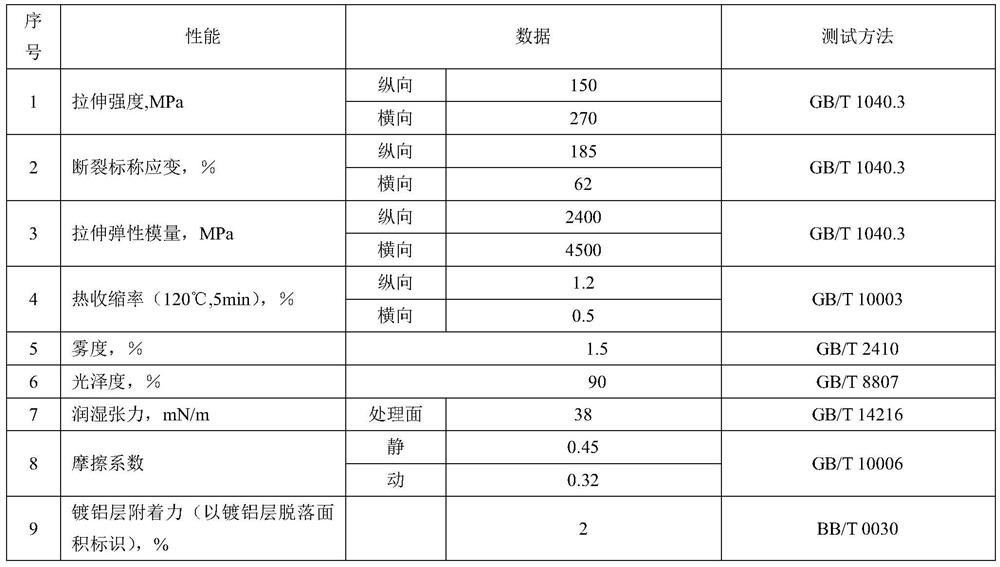

Embodiment 1

[0034] The BOPP base film with high aluminized fastness for low temperature laser molding is composed of an outer layer, a middle layer and an inner layer. The inner layer is a molded layer, and the thickness of the inner layer is 2.5 μm. It is made of the following raw materials in mass percentage: anti-adhesion matrix Material 3%, maleic anhydride graft modified polypropylene 15%, modified molding masterbatch 82%, wherein the modified molding masterbatch is composed of propylene-butadiene-ethylene terpolymer, α-olefin, metallocene linear Low-density polyethylene is made by blending at a mass ratio of 40:30:30, and the propylene-butadiene-ethylene terpolymer is made by copolymerizing propylene, butadiene, and ethylene at a mass ratio of 60:20:20; Adhesion masterbatch is made by blending component 1 and component 2 at a mass ratio of 1:1, wherein component 1 includes the following mass percentages of raw materials: 5% of spherical glass beads with an average particle size of 3 ...

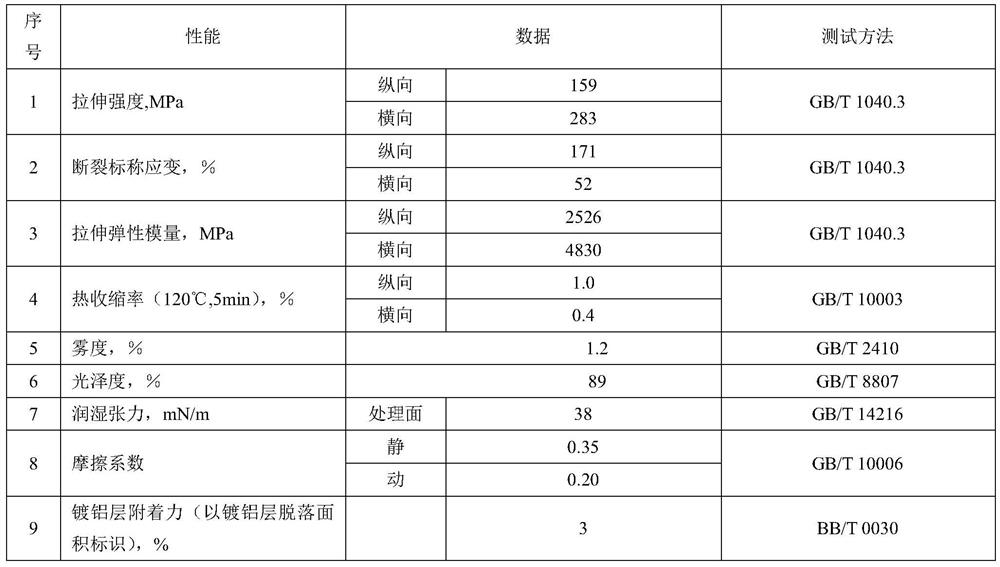

Embodiment 2

[0046] The BOPP base film with high aluminized fastness for low temperature laser molding is composed of an outer layer, a middle layer and an inner layer. The inner layer is a molded layer, and the thickness of the inner layer is 2.5 μm. It is made of the following raw materials in mass percentage: anti-adhesion matrix Material 5%, maleic anhydride graft modified polypropylene 18%, modified molding masterbatch 77%, wherein the modified molding masterbatch is composed of propylene-butadiene-ethylene terpolymer, α-olefin, metallocene linear Low-density polyethylene is made by blending at a mass ratio of 50:25:25, and propylene-butadiene-ethylene terpolymer is made by copolymerizing propylene, butadiene, and ethylene at a mass ratio of 70:15:15; Adhesion masterbatch is made by blending component 1 and component 2 at a mass ratio of 1:1, wherein component 1 includes the following mass percentages of raw materials: 5% of spherical glass beads with an average particle size of 3 μm, ...

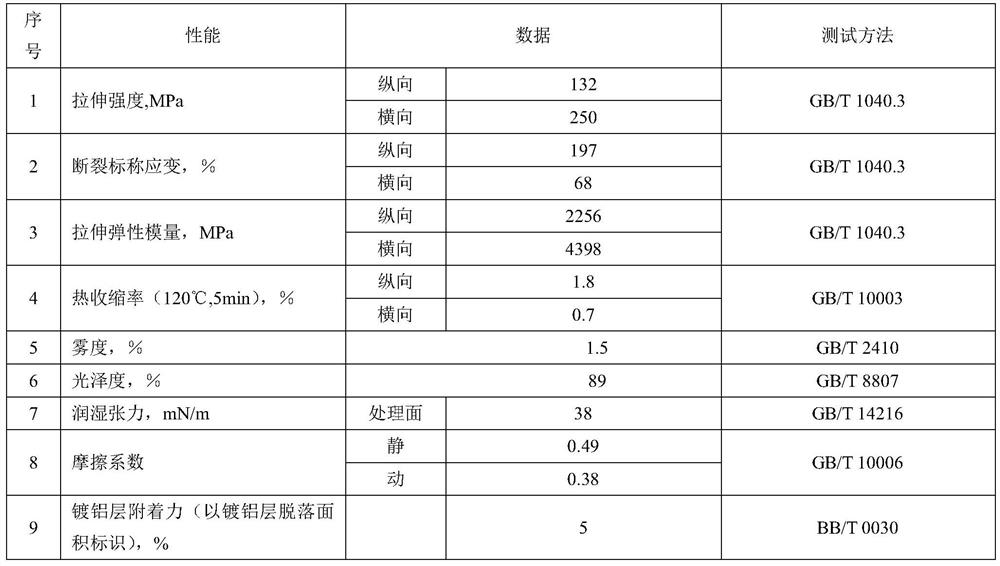

Embodiment 3

[0058] The BOPP base film with high aluminized fastness for low temperature laser molding is composed of an outer layer, a middle layer and an inner layer. The inner layer is a molded layer, and the thickness of the inner layer is 1.8 μm. Material 1%, maleic anhydride graft modified polypropylene 10%, modified molding masterbatch 89%, wherein the modified molding masterbatch is composed of propylene-butadiene-ethylene terpolymer, α-olefin, metallocene linear Low-density polyethylene is made by blending at a mass ratio of 40:20:20, and propylene-butadiene-ethylene terpolymer is made by copolymerizing propylene, butadiene, and ethylene at a mass ratio of 50:10:10; Adhesion masterbatch is made by blending component 1 and component 2 at a mass ratio of 1:0.9, wherein component 1 includes the following mass percentages of raw materials: 4% of spherical glass beads with an average particle size of 2 μm, and the balance is Metallocene linear low-density polyethylene, component two in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com