Film for a tyre inner liner and a production method therefor

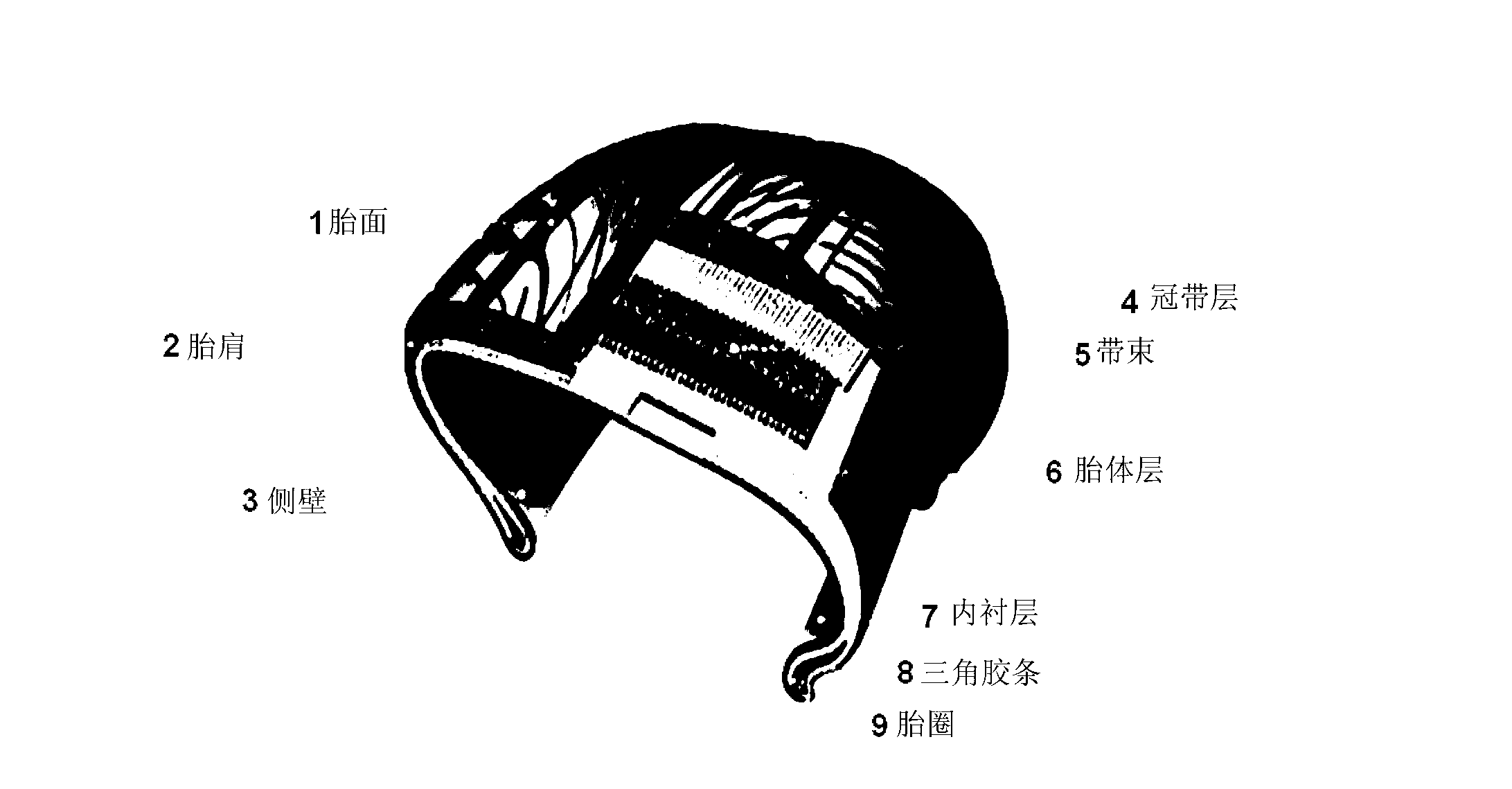

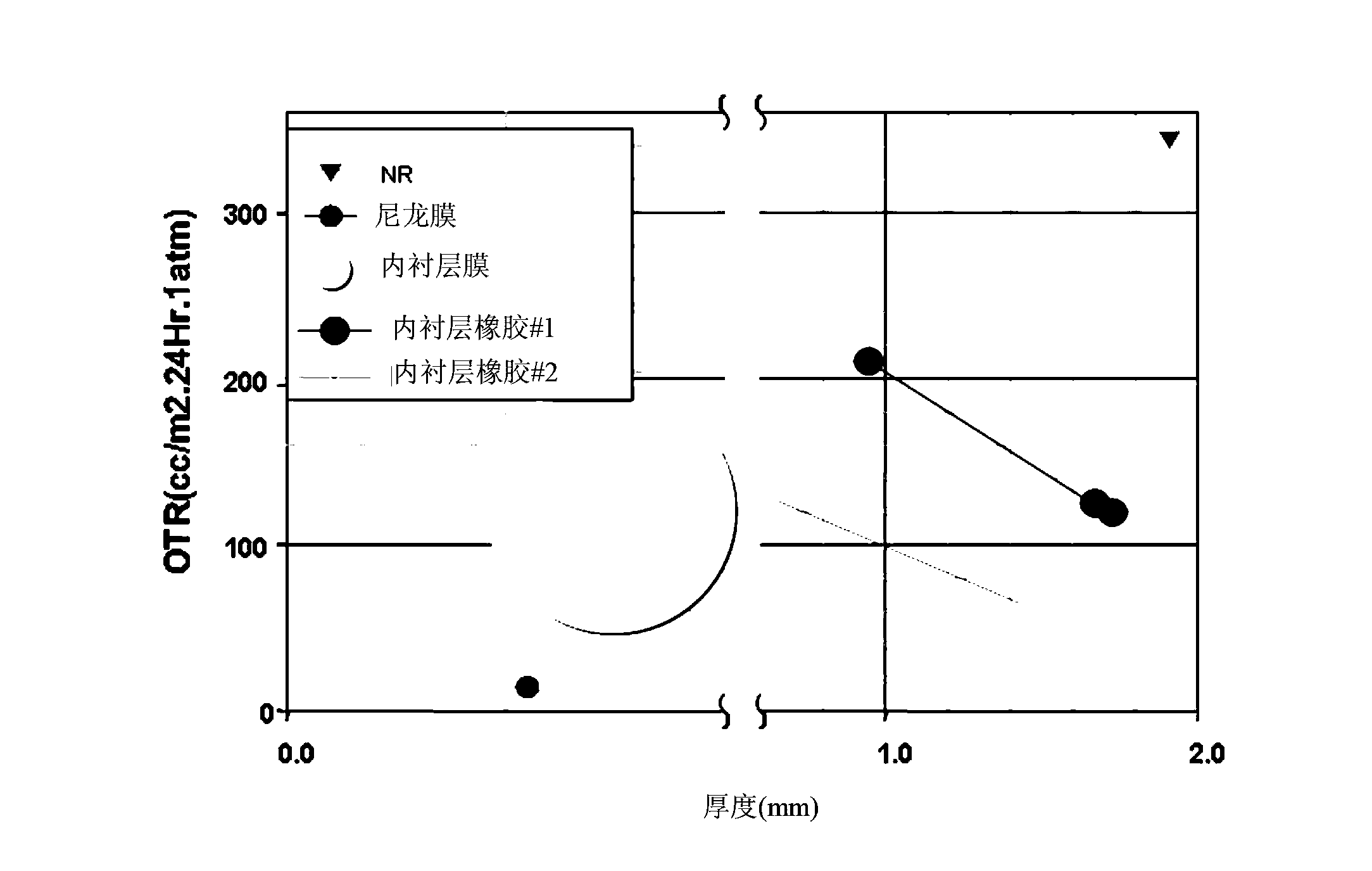

An inner liner and tire technology, applied in special tires, tire parts, tires, etc., can solve the problem of not being able to fully maintain the air permeability of tire molding performance, reducing the thickness and weight of the inner liner, and low fatigue resistance, etc. problems, to achieve the effect of preventing low fuel efficiency and rollover accidents, excellent performance, and improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment and

[0093]

Embodiment 1

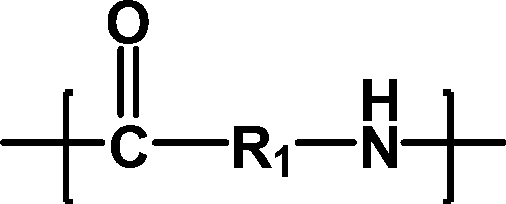

[0095]In order to polymerize the resin used for the inner liner film, a mixture containing 70wt% of ε-caprolactam and 30wt% of polyoxyethylene diamine (Mw. The acids were mixed, and the resulting mixture was melted at 100° C. for 30 minutes under a nitrogen atmosphere. Heat the molten solution at 250°C for 3 hours and pressurize to 8kg / cm 2 , kept at this pressure, and then decompressed to 1kg / cm over 1 hour 2 .

[0096] The product melted under reduced pressure was prepared into chips, and then the chips were extruded through a circular die at 260° C., thereby obtaining a 70 μm thick unstretched film for tire innerliners without performing a 30 m thick unstretched film. / min rate of stretching and heat treatment.

[0097] On the film for the inner liner, a resorcinol-formalin-latex (RFL)-based adhesive was applied to a thickness of 5 μm using a gravure coater, and dried at 150 °C for 1 min and reaction, thereby forming an adhesive layer.

[0098] The thickness of the fil...

Embodiment 2

[0100] A 70 μm thick unstretched film for a tire innerliner was prepared in the same manner as in Example 1 except that 60 wt % of ε-caprolactam and 40 wt % of polyoxyethylene diamine were mixed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com