Buck-boost inverter and control method thereof

A technology of inverter and buck-boost, which is applied in the field of buck-boost inverter and its control, which can solve the problems of reducing system safety and efficiency, so as to improve safety and efficiency, reduce components and reduce circuit cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

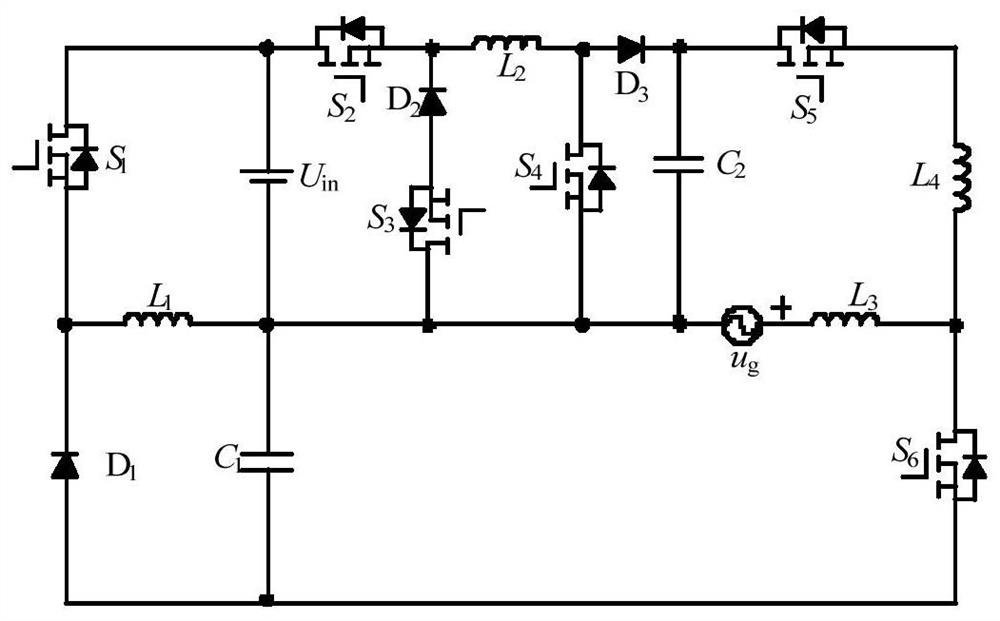

[0048] Such as figure 1 As shown, this embodiment proposes a buck-boost inverter, including a first filter inductor L 1 , the second filter inductance L 2 , the third filter inductance L 3 , the fourth filter inductor L 4 , the first switch tube S 1 , the second switch tube S 2 , the third switch tube S 3 , the fourth switch tube S 4 , the fifth switch tube S 5 , the sixth switch tube S 6 , the first filter capacitor C 1 , the second filter capacitor C 2 , the first diode D 1 , the second diode D 2 , the third diode D 3 ;in,

[0049] The second switch tube S 2 The first end and the input power U in One end and the first switch tube S 1 The first end is connected, the second switching tube S 2 The second terminal and the second diode D 2 Cathode and second filter inductor L 2 One end connection;

[0050] second diode D 2 Anode and the third switch tube S 3 the second end connection;

[0051] The third switch tube S 3 The first end and the input power U ...

Embodiment 2

[0062] On the basis of the buck-boost inverter described in Embodiment 1, this embodiment provides a control method for the buck-boost inverter:

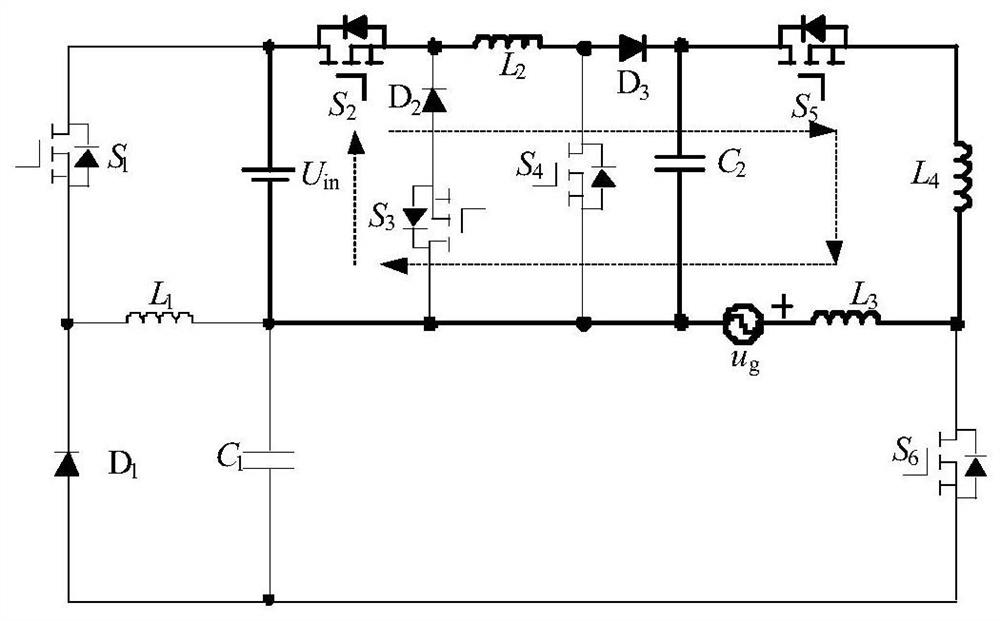

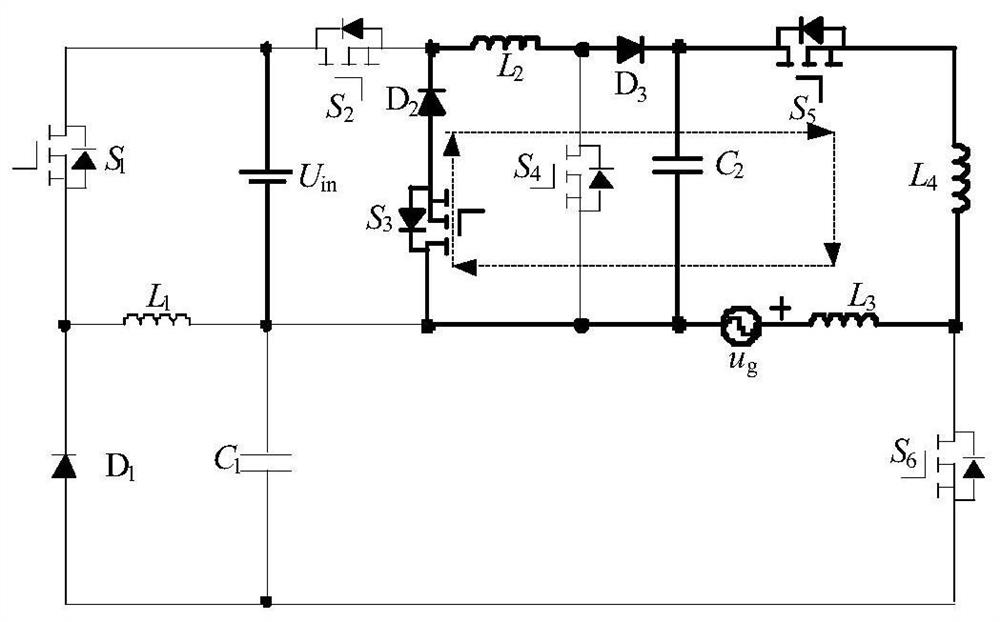

[0063] When input power U in >Output side voltage u g , output side voltage u g In the positive half cycle, the first switching tube S 1 , the fourth switch tube S 4 , the sixth switch tube S 6 Normally off, the third switch tube S 3 , the fifth switch tube S 5 Normally open, the second switch tube S 2 switching high frequency, such as figure 2 and image 3 shown. It can be adjusted by adjusting the second switch tube S 2 The duty cycle to adjust the grid current i g The size of the guarantee grid current i g and grid voltage u g Same frequency and same phase.

[0064] When input power U in >Output side voltage u g , output side voltage u g In the negative half cycle, the second switching tube S 2 , the third switch tube S 3 , the fourth switch tube S 4 , the fifth switch tube S 5 Normally off, the sixth switch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com