Friction lining

A friction lining and body technology, applied in the field of clutches or brakes, friction components, can solve the problems of high energy load and temperature load, affecting the friction lining load, limiting the structural size of the clutch, etc., to achieve improved temperature performance and improved temperature durability The effect of improving the compatibility of materials

Pending Publication Date: 2020-09-22

MIBA FRICTEC

View PDF11 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The structural dimensions of the clutch are also strictly limited due to the need to keep the vehicle weight as low as possible

This in turn strongly affects the load on the friction linings, since the smaller installation space of the clutch means smaller lining surfaces, which leads to higher energy and temperature loads on the friction material

[0007] In contrast to this, the currently known metallic friction linings are all energy and thermally loadable, have a high coefficient of friction and low wear, but are also very prone to frictional vibrations, which can spread over the entire drive train and are therefore very Adversely affect the driving comfort of the vehicle

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment a

[0089] 2 to 6% SnS + 1% to 5% SnS 2 , such as 4% SnS+3% SnS 2

Embodiment b

[0091] 0.5% to 1.5% SnS + 1% and 3% SnS 2 +0.5% and 3% Sn2S3+3.5% and 7.5% hexagonal boron nitride, such as 1% SnS+2SnS 2 +1.5% Sn 2 S 3 +5.5% hexagonal boron nitride

Embodiment c

[0093] 6% to 10% SnS + 2% and 6% FeS, eg 8% SnS + 4% FeS

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

Login to View More

Abstract

Embodiments of the disclosure relate to a binder-free, sintered friction lining, for a friction component of a friction assembly, having a friction lining body, which comprises a metallic matrix, at least one abrasive, solid lubricants, and optionally at least one filling material, wherein the solid lubricants are formed by at least two different solid lubricants, which are selected from a group consisting of hexagonal boron nitride and metal sulfides with at least one metal from the group of tungsten, iron, tin, copper, bismuth, antimony, chromium, zinc, silver, manganese, molybdenum.

Description

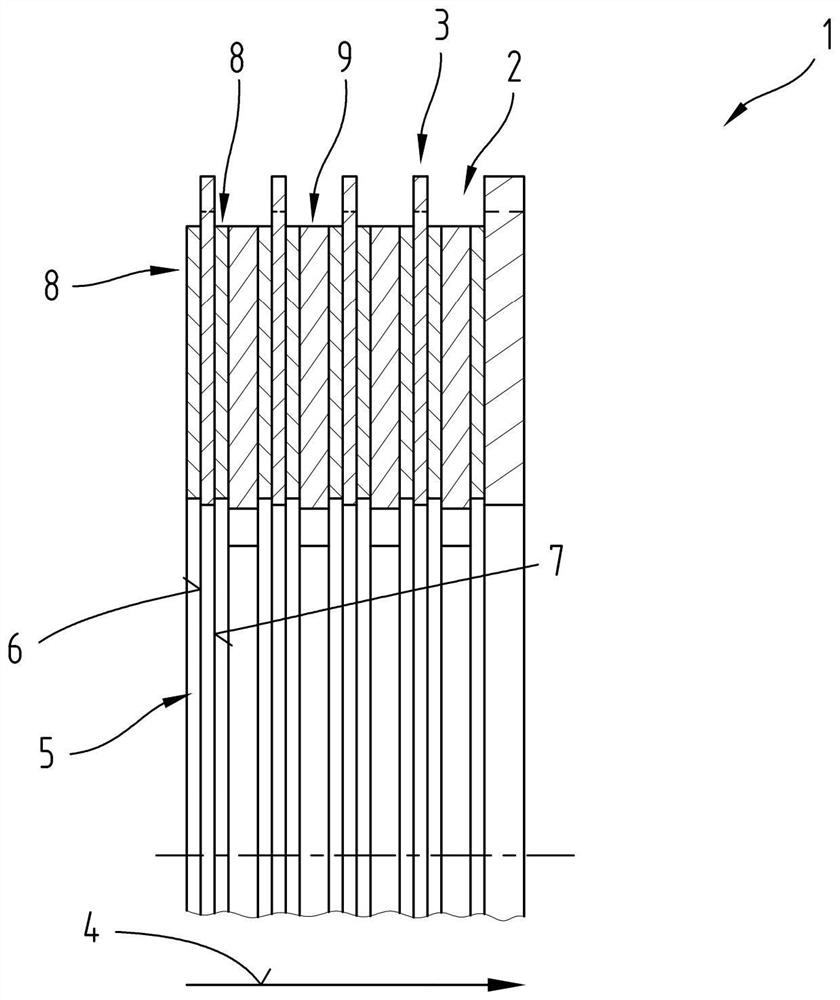

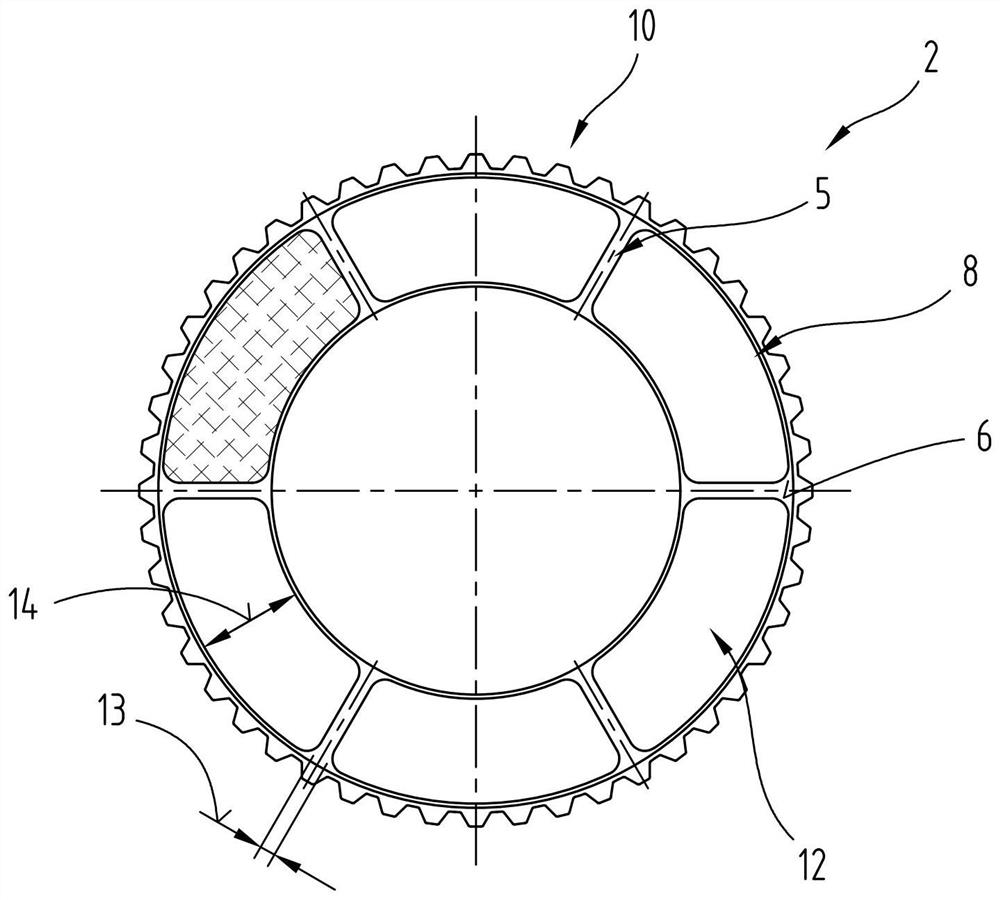

technical field [0001] The present application relates to a binder-free, sintered friction lining having a friction lining body comprising a metal matrix, at least one abrasive, a solid lubricant and optionally at least one filler. [0002] The invention also relates to a friction component having a support on which a friction lining is arranged. [0003] Furthermore, the invention relates to a friction assembly, in particular a clutch or brake, which has at least one friction component. Background technique [0004] Resin-bonded friction linings are used in conventional dry-running drive trains of motor vehicles. For example, DE 2924 540 A describes products for the production of structural elements having a metal composition, which are formed from at least one fine steel fiber powder. This fibrous powder is used in the friction linings of brakes in proportions of 30 to 85% by weight. The friction lining contains between 10 and 20% of a polymerizable phenolic binder. ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): F16D69/02F16N15/00C10M125/00C10N30/06B22F1/10

CPCB22F5/00B22F7/008C22C1/05C22C29/14C22C32/00F16D13/00F16D69/02B22F1/10F16D69/027F16N15/00C10M125/00F16D2200/0073C10M2201/061C10M2201/065C10M2201/066B22F7/08C22C32/0089C22C1/0425C22C32/0084F16D13/648C22C32/0068F16D2200/0052

Inventor M·穆勒格尔

Owner MIBA FRICTEC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com