Rotary dobby, weaving loom equipped with such a dobby and driving element for such a dobby

A technology for driving elements and actuating elements, applied in the direction of dobby, textile, textile and paper making, etc., can solve the problems of breaking, limiting the performance of the dobby, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

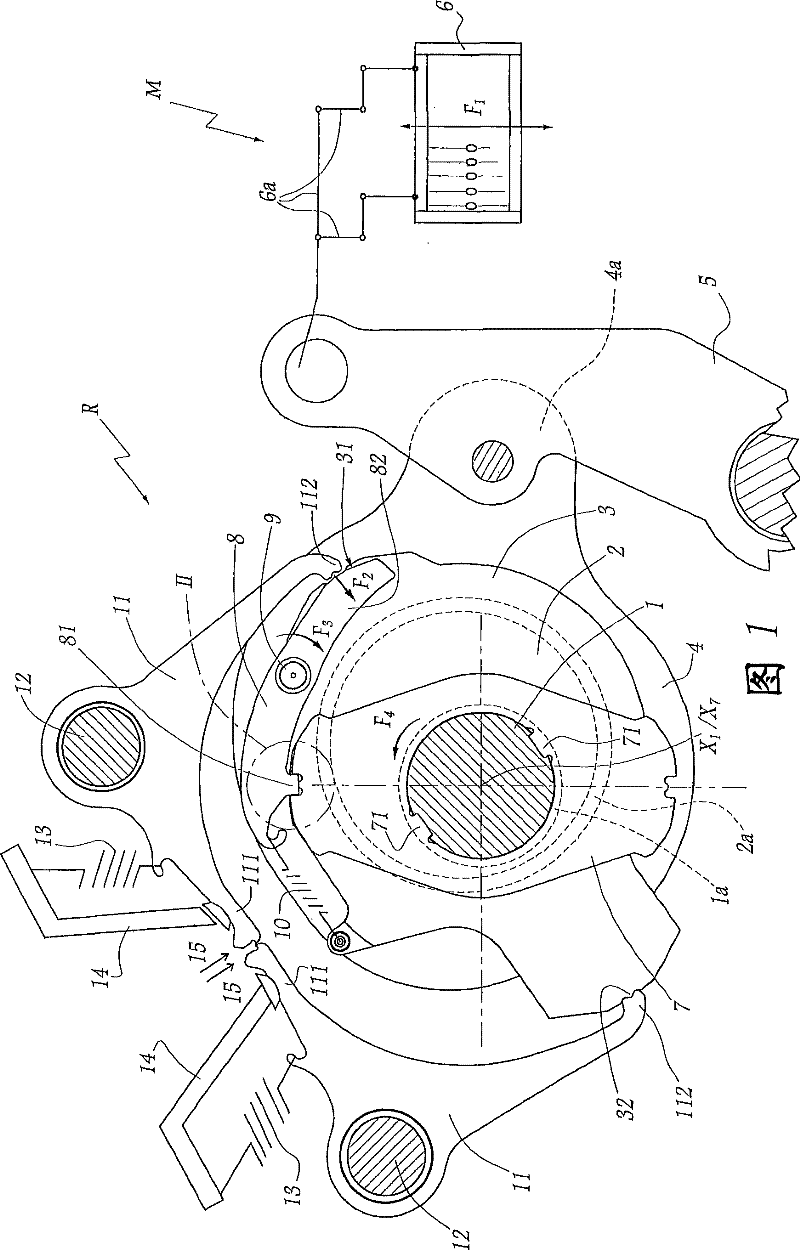

[0028] exist Figure 1-3 The dobby R shown in includes an intermittently rotating main shaft 1 that stops every half revolution. The bushing has bearings 1a equal in number to the number of heald frames or lifting units of the loom. An eccentric 2 fixed laterally to the plate 3 is idly mounted on each bearing 1a. Around each eccentric 2 there is provided a bearing 2a, a connecting piece 4, the free end 4a of which is coupled to a pivot arm 5 which causes the heald frame or lifting unit 6 to move through the link formed by the connecting piece 6a. vertical movement. The heald frame is in figure 1 shown schematically.

[0029] Thus, the loom M is included in figure 1 Shown on the left is a dobby R with a plurality of heald frames such as 6, each heald frame 6 is vertically oscillated by means of a rod 5, as indicated by the double arrow F1, which is itself connected by a connecting piece 4. move.

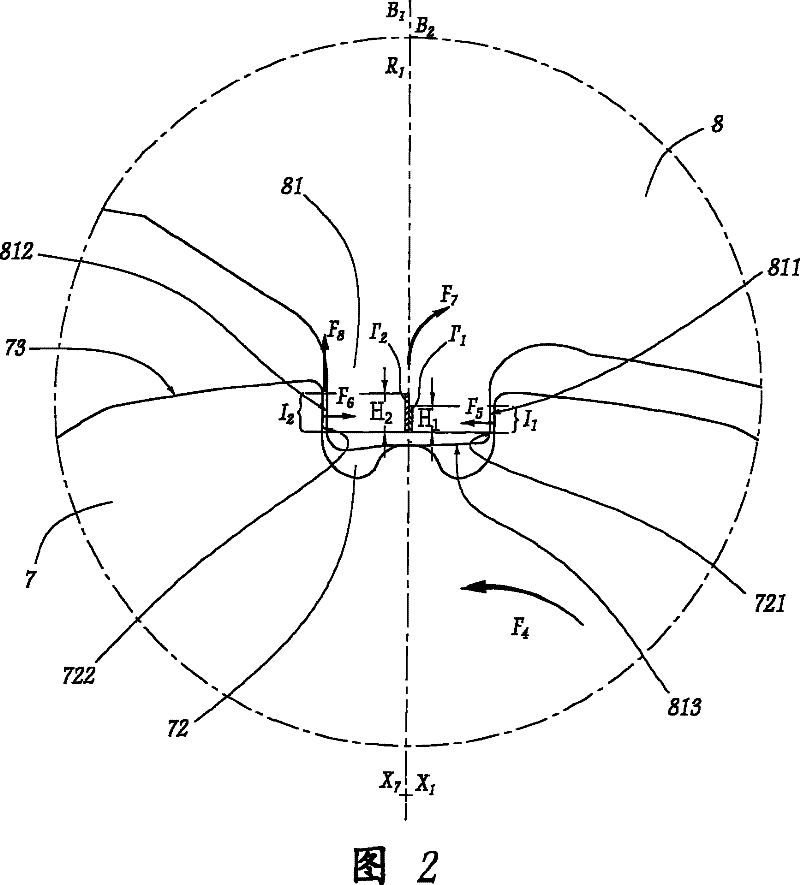

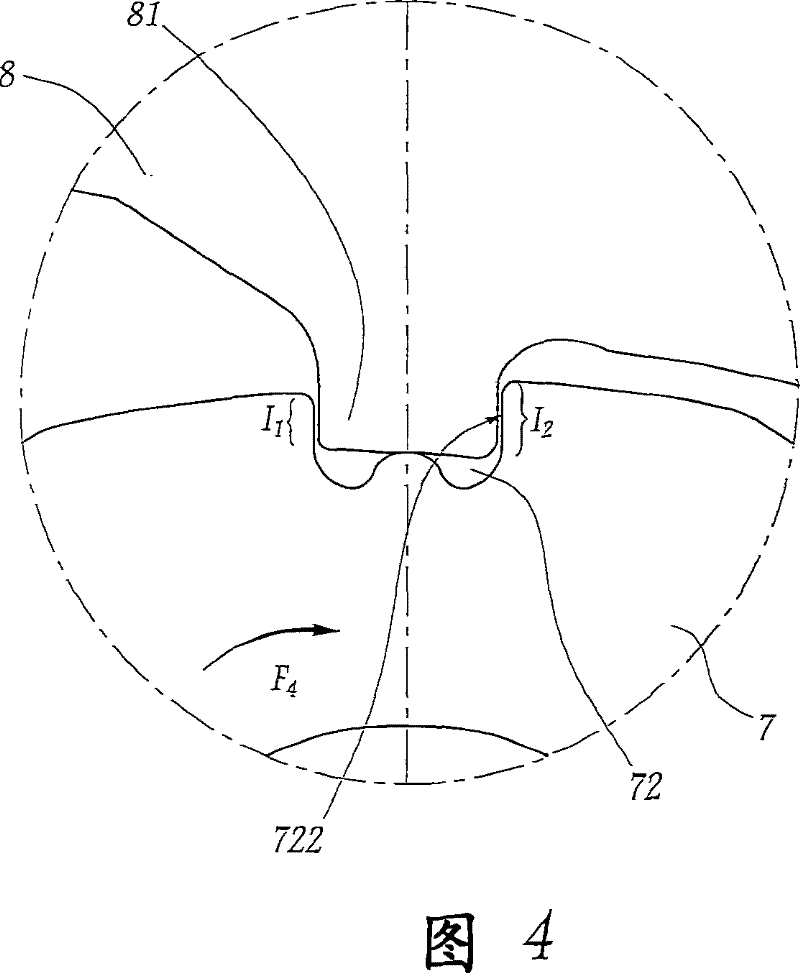

[0030] The longitudinal geometric axis of axis 1 is defined by the X 1 me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com