Lightweight and high-performance electromagnetic shielding coating and its preparation technology and construction technology

An electromagnetic shielding coating and construction technology technology, applied in conductive coatings, fire-retardant coatings, coatings, etc., can solve the problems of unavailability, insufficient shielding efficiency, and poor low temperature cold brittleness resistance, and achieves increased electromagnetic wave reflection attenuation, Taking into account the mechanical properties of the coating and enhancing the effect of shielding effectiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

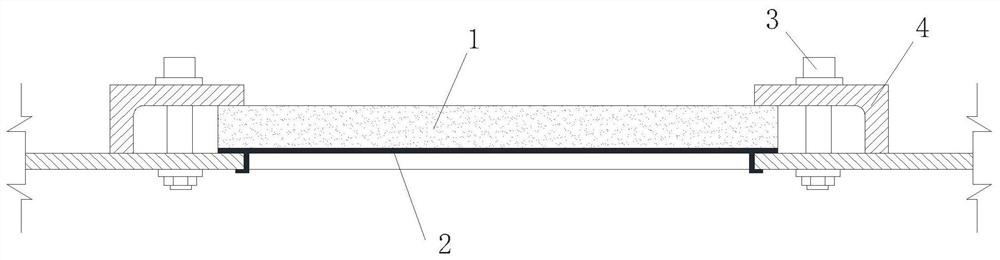

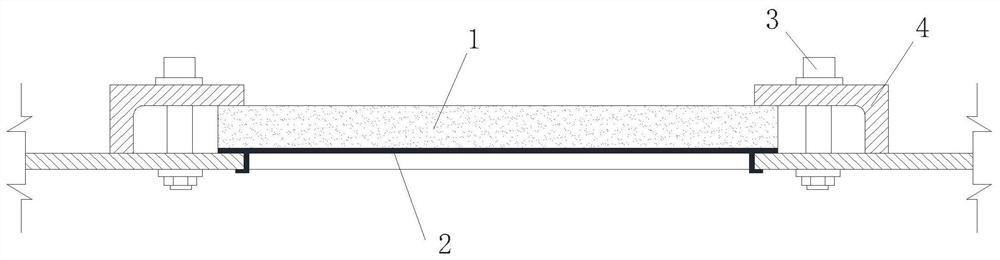

Image

Examples

Embodiment 1

[0040] A preparation process of a lightweight high-performance electromagnetic shielding coating, comprising the steps of:

[0041] Put 15% of the hollow silver fiber, 5% of absolute ethanol, and 5% of butanol in a magnetic stirring tank and stir evenly, control the speed not to exceed 50 rpm, slowly add 0.3% of the dispersant dropwise, and mix well;

[0042] Pour the remaining 5% absolute ethanol and 10% butanol into the above-mentioned hollow silver fiber slurry, ultrasonically vibrate, and slowly add the resin mixture while oscillating for 15 minutes;

[0043] Finally, 0.1% of the anti-sedimentation wax slurry is added, stirred and mixed to obtain a light-weight high-performance electromagnetic shielding coating.

[0044] Its performance parameters are as follows:

[0045] Conductivity 10 4 Siemens, 1G electromagnetic shielding 65db.

[0046] Bending 1mm round rod, resistant to low temperature -40℃.

Embodiment 2

[0048] A preparation process of a lightweight high-performance electromagnetic shielding coating, comprising the steps of:

[0049] Put 20% of the hollow silver fiber, 7% of absolute ethanol, and 10% of butanol in a magnetic stirring tank and stir evenly, control the speed not to exceed 50 rpm, slowly add 0.4% of the dispersant dropwise, and mix well;

[0050] Pour the remaining 5% absolute ethanol and 5% butanol into the above-mentioned hollow silver fiber slurry, ultrasonically vibrate, and slowly add the resin mixture while oscillating for 15 minutes;

[0051] Finally, 0.2% of the anti-sedimentation wax slurry is added, stirred and mixed to obtain a light-weight high-performance electromagnetic shielding coating.

[0052] Its performance parameters are as follows:

[0053] 1GHz shielding effectiveness is 65db, 3GHz shielding effectiveness is 67db, and 10GHz shielding effectiveness is 70db.

Embodiment 3

[0055] A preparation process of a lightweight high-performance electromagnetic shielding coating, comprising the steps of:

[0056] Put 24% of the hollow silver fiber, 5% of absolute ethanol, and 7% of butanol in a magnetic stirring tank and stir evenly, control the speed not to exceed 50 rpm, slowly add 0.8% of the dispersant dropwise, and mix well;

[0057] Pour the remaining 5% absolute ethanol and 7% butanol into the above-mentioned hollow silver fiber slurry, oscillate ultrasonically, and slowly add the resin mixture while oscillating for 15 minutes;

[0058] Finally, 0.2% of the anti-sedimentation wax slurry is added, stirred and mixed to obtain a light-weight high-performance electromagnetic shielding coating.

[0059] Its performance parameters are as follows:

[0060] 1GHz shielding effectiveness is 67db, 3GHz shielding effectiveness is 70db, and 10GHz shielding effectiveness is 75%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com