A kind of hydrogenation treatment catalyst and preparation method thereof

A hydrogenation treatment and catalyst technology, applied in the direction of physical/chemical process catalysts, chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problem of expensive active metal components and active components Problems such as low utilization rate and reduced selectivity of the catalyst can achieve the effect of reasonable component distribution, high utilization rate and improved selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

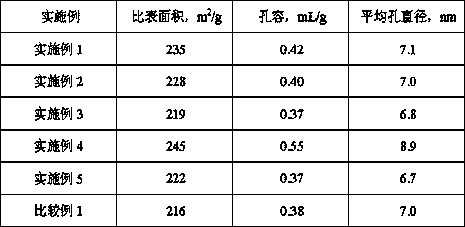

Examples

Embodiment 1

[0033] (1) Preparation of Mo-Ni-P aqueous solution:

[0034] 5.3g phosphoric acid H 3 PO 4 (concentration 85 wt%) was dissolved in 80mL water, then added 18.6g molybdenum trioxide and 6.8g basic nickel carbonate, heated to 100°C and stirred and refluxed for 2.0h, filtered and set to 100mL to obtain Mo-Ni-P aqueous solution. where MoO 3The concentration of NiO is 0.18g / mL, the concentration of NiO is 0.037g / mL, and the concentration of P is 0.014g / mL.

[0035] (2) Preparation of catalyst:

[0036] Measure 49mL of Mo-Ni-P aqueous solution and dilute it to 100mL, add to 75.2g of alumina support (pore volume is 0.65mL / g, specific surface area is 295m 2 / g, cylinder, diameter 0.8mm), stirred at 70°C until the solution was evaporated to dryness, dried the obtained solid at 110°C for 8.0h, and then calcined at 450°C for 3.0h to prepare catalyst precursor A; then added In the high-pressure reactor, heat up to 450°C under a hydrogen atmosphere, treat at 0.3 MPa for 4 hours, drop ...

Embodiment 2

[0042] (1) Preparation of Mo-Ni-P aqueous solution:

[0043] 6.1g phosphoric acid H 3 PO 4 (concentration 85 wt%) was dissolved in 80mL of water, then added 20.9g of molybdenum trioxide and 7.6g of basic nickel carbonate, heated to 100°C, stirred and refluxed for 2.0h, and filtered to 100mL to obtain Mo-Ni-P aqueous solution. where MoO 3 The concentration of NiO was 0.21 g / mL, that of NiO was 0.041 g / mL, and that of P was 0.017 g / mL.

[0044] (2) Preparation of catalyst:

[0045] Measure 32 mL of Mo-Ni-P aqueous solution and dilute it to 100 mL, add to 72.3 g of alumina carrier (pore volume is 0.65 mL / g, specific surface area is 295 m 2 / g, cylinder, diameter 0.8mm), stirred at 70°C until the solution was evaporated to dryness, dried the obtained solid at 110°C for 8.0h, and then calcined at 450°C for 3.0h to prepare catalyst precursor A; then added In the high-pressure reactor, heat up to 450°C under a hydrogen atmosphere, treat at 0.3 MPa for 4 hours, drop to the react...

Embodiment 3

[0051] (1) Preparation of Mo-Ni-P aqueous solution:

[0052] 7.0g phosphoric acid H 3 PO 4 (concentration 85 wt%) was dissolved in 80mL of water, then added 23.0g of molybdenum trioxide and 8.5g of basic nickel carbonate, heated to 100°C, stirred and refluxed for 2.0h, and filtered to 100mL to obtain Mo-Ni-P aqueous solution. where MoO 3 The concentration of NiO was 0.23 g / mL, that of NiO was 0.046 g / mL, and that of P was 0.019 g / mL.

[0053] (2) Preparation of catalyst:

[0054] Measure 24 mL of Mo-Ni-P aqueous solution and dilute it to 100 mL, add to 69.5 g of alumina carrier (pore volume is 0.65mL / g, specific surface area is 295m 2 / g, cylinder, diameter 0.8mm), stirred at 70°C until the solution was evaporated to dryness, dried the obtained solid at 110°C for 8.0h, and then calcined at 450°C for 3.0h to prepare catalyst precursor A; then added In the high-pressure reactor, heat up to 450°C under a hydrogen atmosphere, treat at 0.3 MPa for 4 hours, drop to the reactio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com