Production method and device of nickel sulfate solution

A production method and technology of a production device are applied in the field of production methods and devices of nickel sulfate solution, can solve the problems of high energy consumption and cost, low dissolution rate of nickel raw materials, etc., reduce energy consumption and production cost, and have no impact on product quality , the effect of increasing the dissolution rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

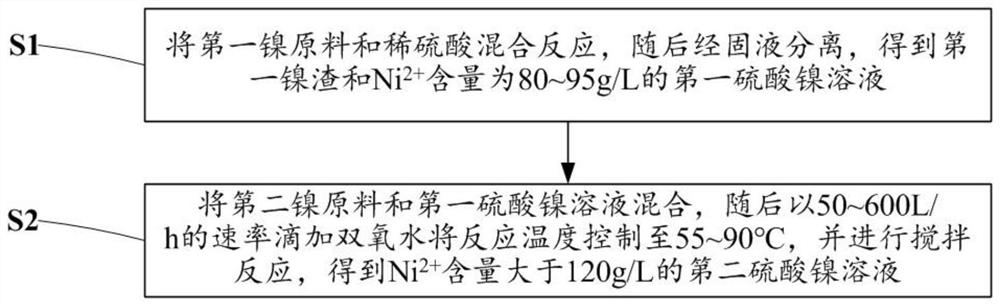

Method used

Image

Examples

Embodiment 1

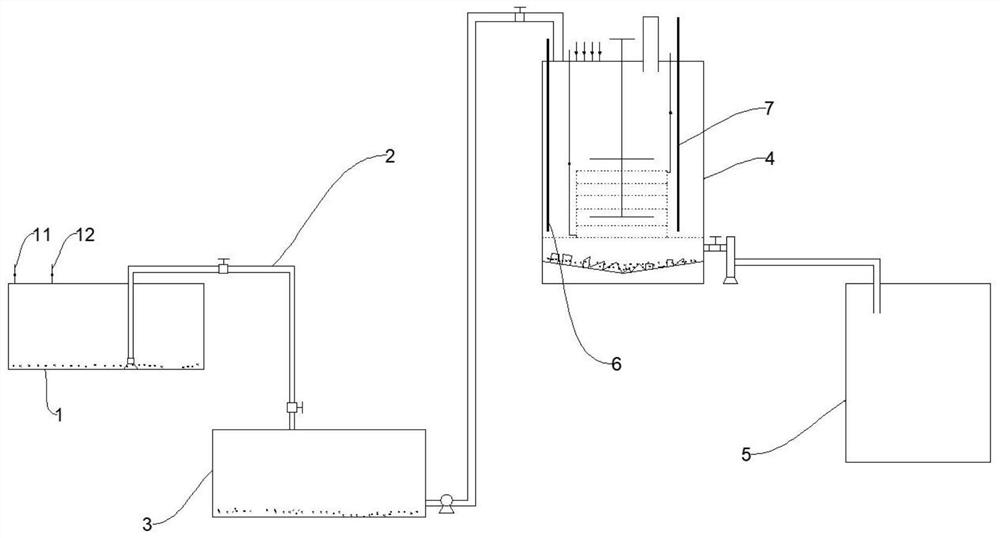

[0046] Add 2t nickel powder and 3m 3 Concentration is the dilute sulfuric acid of 2.5mol / L, after reaction 8 days, obtain the first nickel sulfate solution; Nickel ion content is 91.8g / L in the first nickel sulfate solution of gained, H + The content is 1.6mol / L. Subsequently, use the siphon to transport the first nickel sulfate solution in the upper tank to the lower tank for standby. After conveying, add 0.3t nickel powder and 3m 3 Concentration is 2.5mol / L dilute sulfuric acid, repeat the above-mentioned preparation process of the first nickel sulfate solution.

[0047] Add 2t nickel powder, 12m 3 The first nickel sulfate solution; start stirring, and add mass fraction of 27.5% hydrogen peroxide at a rate of 200-600 L / h, the catalytic reaction proceeds, and a large amount of heat is generated during the reaction to heat up the solution. After 12 hours of reaction, the first solution is obtained. Nickel disulfate solution. The pH of the obtained second nickel sulfate so...

Embodiment 2

[0051] Add 2t nickel powder and 3m 3 Concentration is the dilute sulfuric acid of 2.5mol / L, after reaction 8 days, obtain the first nickel sulfate solution; Nickel ion content is 83.7g / L in the first nickel sulfate solution of gained, H + The content is 1.7mol / L. Subsequently, use the siphon to transport the first nickel sulfate solution in the upper tank to the lower tank for standby. After conveying, add 0.3t nickel powder and 3m 3 Concentration is 2.5mol / L dilute sulfuric acid, repeat the above-mentioned preparation process of the first nickel sulfate solution.

[0052] Add 2t nickel powder, 12m 3 The first nickel sulfate solution; start stirring, and add mass fraction of 27.5% hydrogen peroxide at a rate of 200-600 L / h, the catalytic reaction proceeds, and a large amount of heat is generated during the reaction to heat up the solution. After 12 hours of reaction, the first solution is obtained. Nickel disulfate solution. The pH of the obtained second nickel sulfate so...

Embodiment 3

[0056] Add 2t nickel powder and 3m 3 Concentration is the dilute sulfuric acid of 2.5mol / L, after reaction 8 days, obtain the first nickel sulfate solution; Nickel ion content is 87.5g / L in the first nickel sulfate solution of gained, H + The content is 1.6mol / L. Subsequently, use the siphon to transport the first nickel sulfate solution in the upper tank to the lower tank for standby. After conveying, add 0.3t nickel powder and 3m 3 Concentration is 2.5mol / L dilute sulfuric acid, repeat the above-mentioned preparation process of the first nickel sulfate solution.

[0057] Add 2t nickel powder, 12m 3 The first nickel sulfate solution; start stirring, and add mass fraction of 27.5% hydrogen peroxide at a rate of 50-200 L / h, the catalytic reaction proceeds, and a large amount of heat is generated during the reaction to heat up the solution. After 33 hours of reaction, the first solution is obtained. Nickel disulfate solution. The pH of the obtained second nickel sulfate sol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com