Airflow portable type powdery material conveying device and method

A powdery material and conveying device technology, which is applied in the direction of conveyors, transportation and packaging, and conveying bulk materials, etc., can solve the problems of poor use effect, poor material circulation effect, and inability to uniformly feed materials, etc., to achieve low design and use costs , easy to adjust, avoid the effect of hard contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

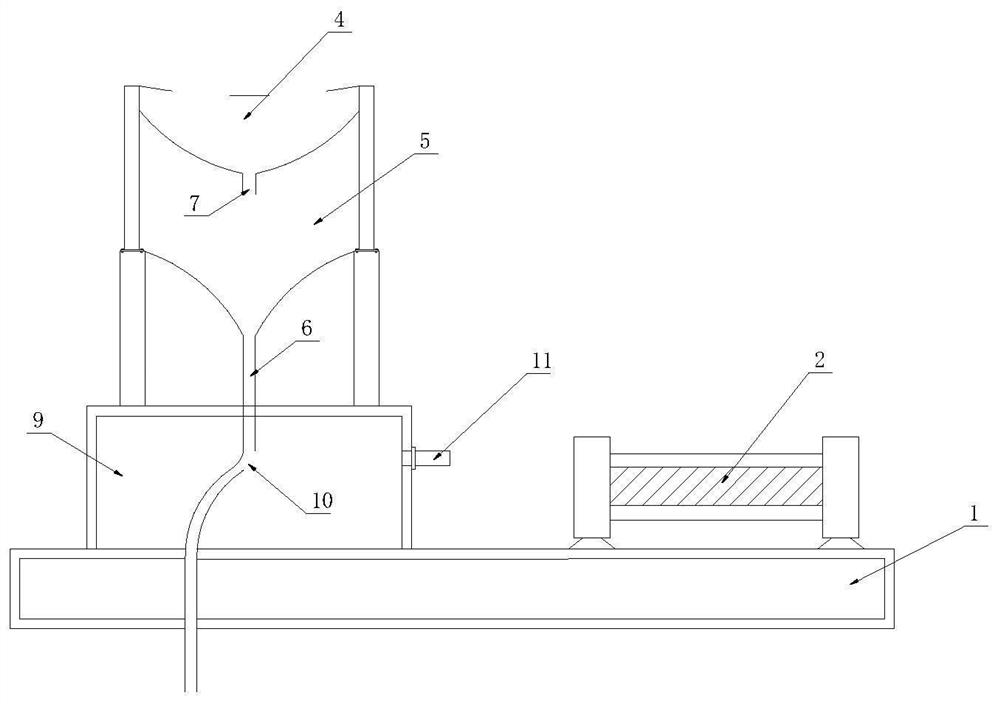

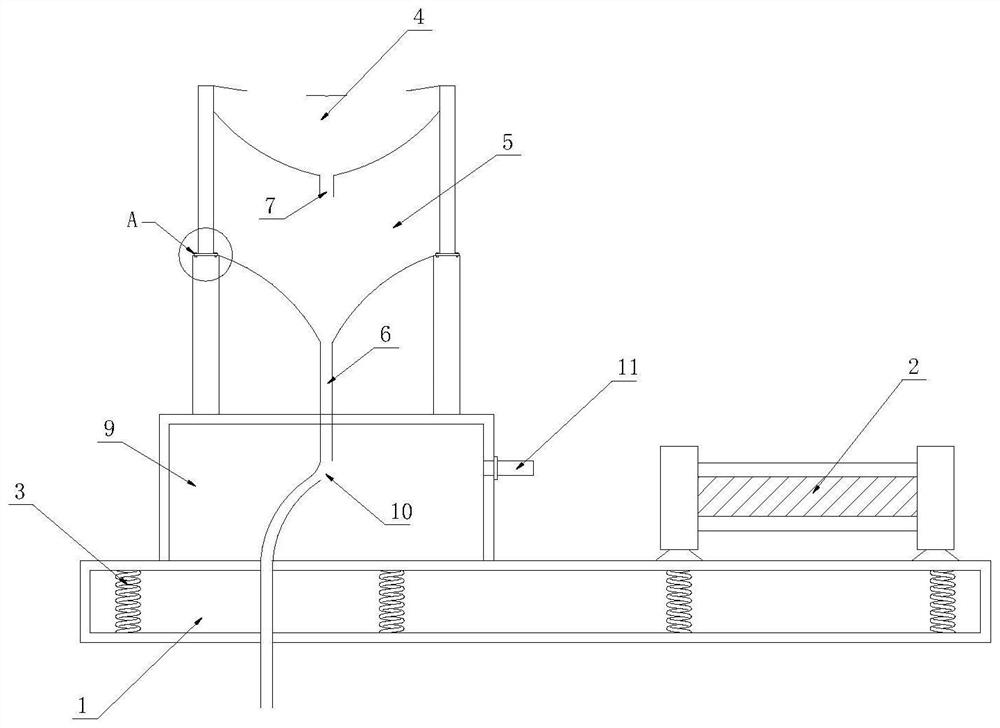

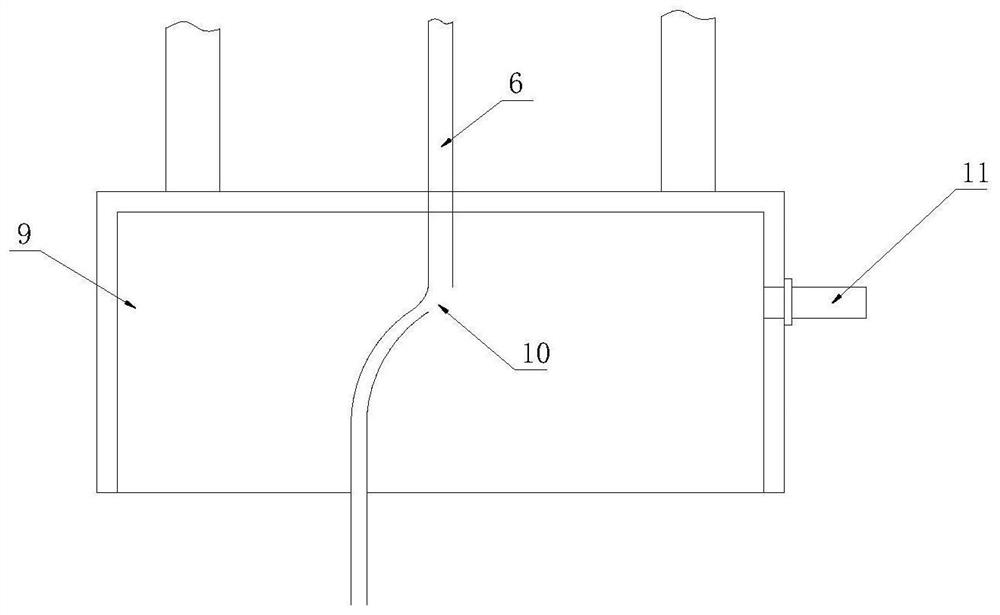

[0030] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

[0031] The invention is mainly aimed at the research field of pyrolysis and combustion of certain materials, and particle flow, and particularly relates to the design method of biomass powder, coal powder, and particulate matter supply devices.

[0032] Take the experimental study of rapid and flash pyrolysis of biomass as an example: the heating rate in the pyrolysis reactor is fast, which requires small particle size and small amount of materials entering the furnace. Therefore, the continuous and stable feeding of the material supply device to the pyrolysis reaction zone plays an important role in the smooth progress of the pyrolysis experiment. At present, when scientific research units conduct pyrolysis reaction experiments on experimental platforms such as fixed bed reactors, f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com