Surface microstructure array with bacterial adhesion resistance and forming method of surface microstructure array

A microstructure array, anti-bacterial adhesion technology, applied in 3D object support structures, additive manufacturing, manufacturing tools, etc., can solve the problems of low antibacterial efficiency, difficult to form functional surface microstructures, etc., and achieve good self-cleaning performance. The effect of controllable microstructure morphology and size and improving molding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

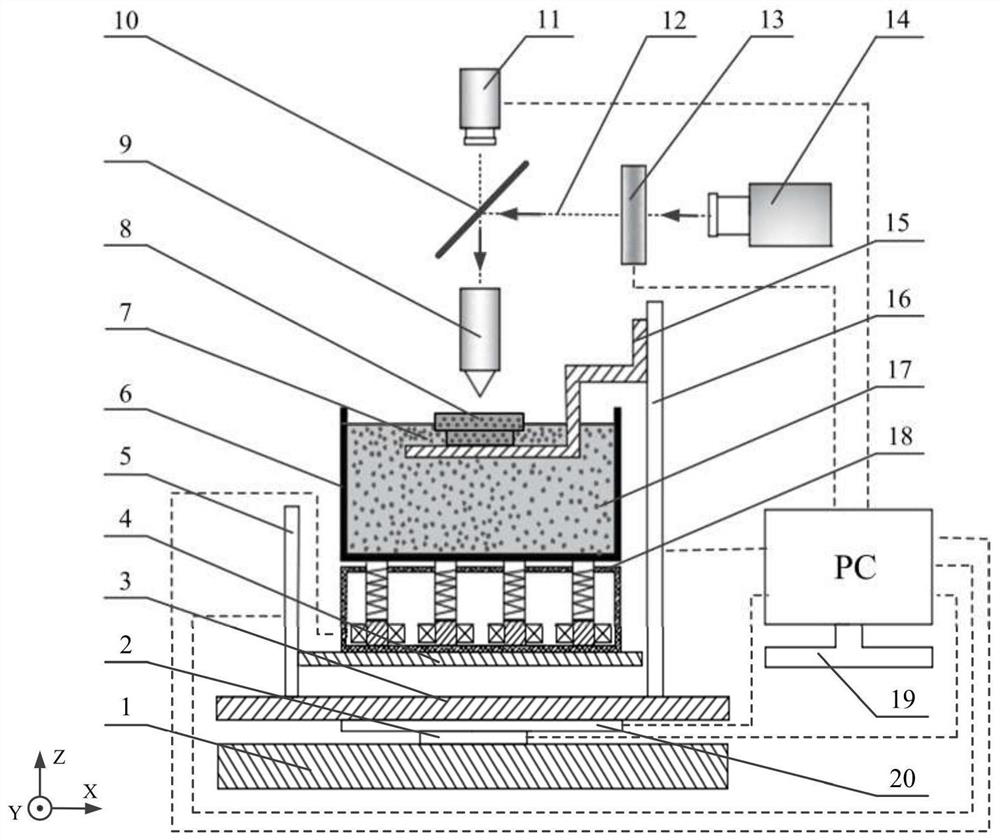

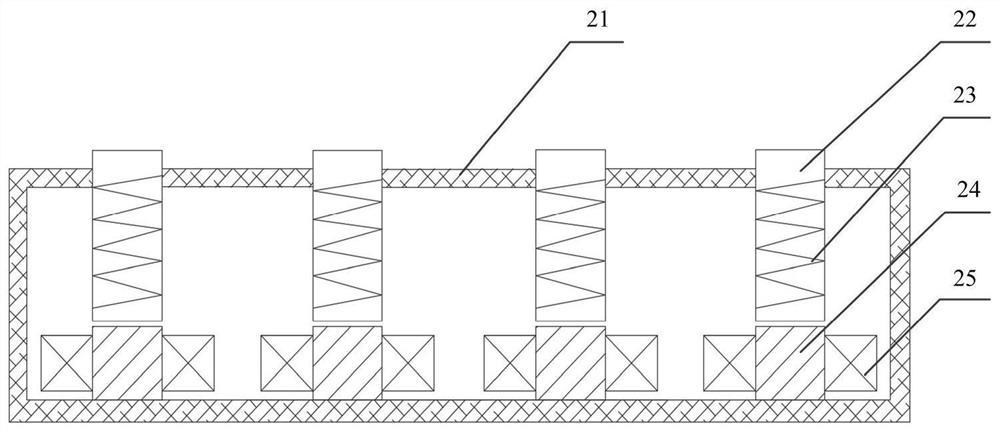

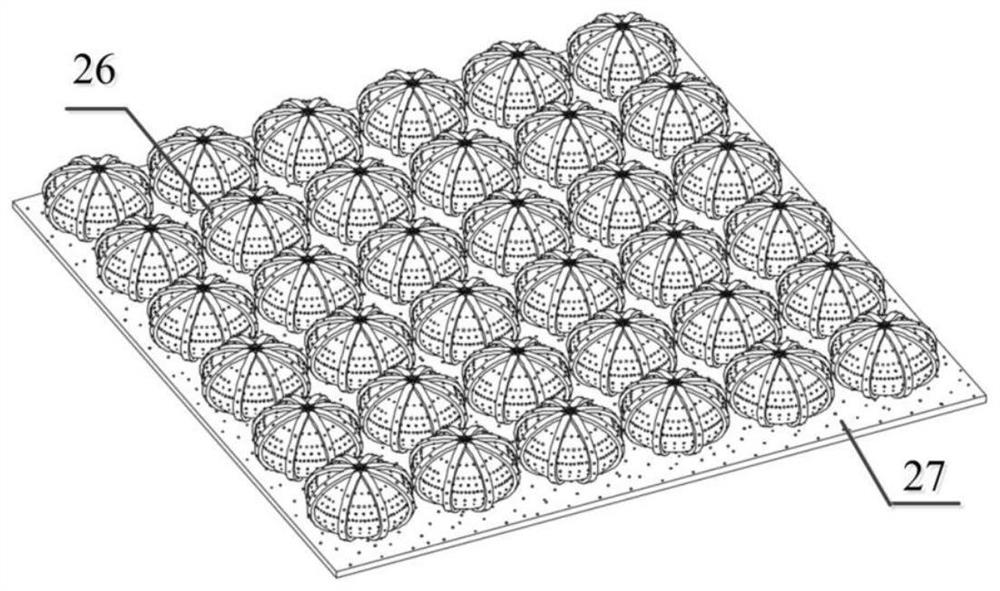

[0021] See attached Figure 1~4 , the single microstructure of the surface microstructure array with anti-bacterial adhesion performance is a sea urchin pavilion structure 28, the material is a photosensitive resin 7, and its horizontal size, vertical size and spacing are all in micron order; the sea urchin pavilion structure 28 is a regular ellipse Spherical, with a maximum diameter of 10µm and a pitch of 1µm; 8 reinforcing ribs are uniformly distributed along the ellipsoid ring, the width of which is 1µm, and the angle between each reinforcing rib is 45°; on the surface of the microstructure, nanoparticles are distributed 17, thereby forming a micro / nano composite structure with the sea urchin pavilion structure 28; a plurality of the above composite structures are evenly distributed on the target surface 27 of the molded part, that is, a surface microstructure array 26 is formed.

[0022] The method for forming the surface microstructure array 26 with anti-bacterial adhesion...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com