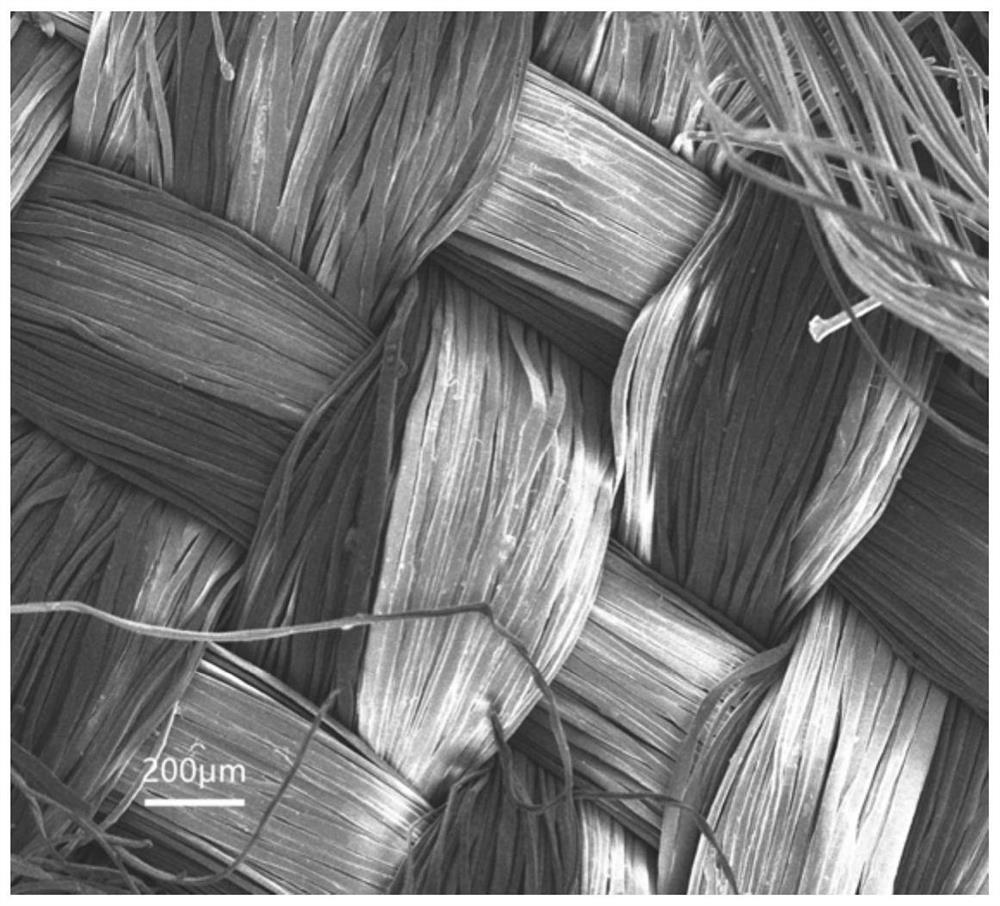

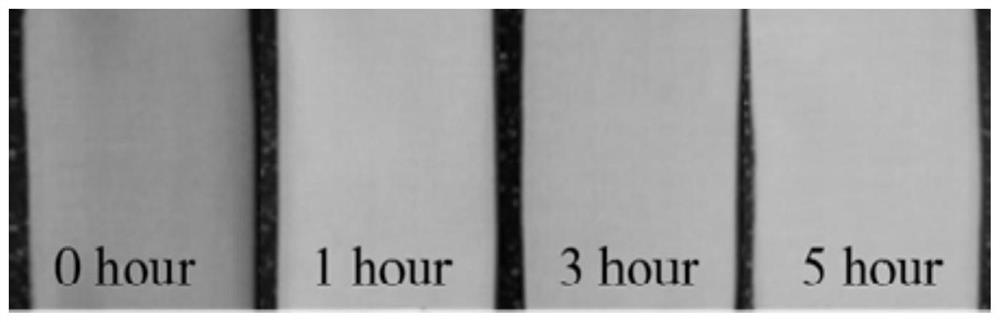

Protective clothing fabric and preparation method thereof

A technology for protective clothing and fabrics, applied in plant fibers, fiber processing, textiles and papermaking, etc., can solve problems such as limited self-cleaning effect, reduced fabric air permeability, human health hazards, etc., to achieve excellent self-cleaning performance, small size, The effect of mild processing conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] TiO 2 -SiO 2 -The preparation method of ZnO hybrid nano-sol, comprises the steps:

[0042] ①At room temperature, mix titanium tetraisopropoxide with isopropanol and stir for 5 minutes to form an isopropanol solution of titanium tetraisopropoxide;

[0043] ②At room temperature, mix tetraethyl orthosilicate and isopropanol, and stir for 5 minutes to form an isopropanol solution of tetraethyl orthosilicate;

[0044] ③Under room temperature, mix zinc nitrate and citric acid aqueous solution, stir for 5 minutes to form zinc nitrate, citric acid aqueous solution;

[0045] The isopropanol solution of the tetraisopropoxytitanium obtained in step 1, the isopropanol solution of tetraethyl orthosilicate obtained in step 2 and the aqueous solution of zinc nitrate citric acid obtained in step 3 are mixed, and then continue Stir for 10 minutes to obtain the TiO 2 -SiO 2 -ZnO hybrid nano sol;

[0046] In step 1., the volume ratio of titanium tetraisopropoxide and isopropanol is ...

Embodiment 2

[0059] TiO 2 -SiO 2 -The preparation method of ZnO hybrid nano-sol, comprises the steps:

[0060] ①At room temperature, mix titanium tetraisopropoxide with isopropanol and stir for 8 minutes to form an isopropanol solution of titanium tetraisopropoxide;

[0061] ②At room temperature, mix tetraethyl orthosilicate and isopropanol, and stir for 8 minutes to form an isopropanol solution of tetraethyl orthosilicate;

[0062] ③Under room temperature, zinc nitrate and citric acid aqueous solution were mixed, stirred for 8 minutes to form an aqueous solution of zinc nitrate and citric acid;

[0063] The isopropanol solution of the tetraisopropoxytitanium obtained in step 1, the isopropanol solution of tetraethyl orthosilicate obtained in step 2 and the aqueous solution of zinc nitrate citric acid obtained in step 3 are mixed, and then continue Stir for 60 minutes to obtain the TiO 2 -SiO 2 -ZnO hybrid nano sol;

[0064] In step 1., the volume ratio of titanium tetraisopropoxide ...

Embodiment 3

[0078] TiO 2 -SiO 2 -The preparation method of ZnO hybrid nano-sol, comprises the steps:

[0079] ①At room temperature, mix titanium tetraisopropoxide with isopropanol and stir for 6 minutes to form an isopropanol solution of titanium tetraisopropoxide;

[0080] ②At room temperature, mix tetraethyl orthosilicate and isopropanol, and stir for 6 minutes to form an isopropanol solution of tetraethyl orthosilicate;

[0081] ③At room temperature, mix zinc nitrate and citric acid aqueous solution, and stir for 6 minutes to form an aqueous solution of zinc nitrate and citric acid;

[0082] The isopropanol solution of the tetraisopropoxytitanium obtained in step 1, the isopropanol solution of tetraethyl orthosilicate obtained in step 2 and the aqueous solution of zinc nitrate citric acid obtained in step 3 are mixed, and then continue Stir for 30 minutes to obtain the TiO 2 -SiO 2 -ZnO hybrid nano sol;

[0083] In step 1., the volume ratio of titanium tetraisopropoxide and isopr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Water contact angle | aaaaa | aaaaa |

| Water contact angle | aaaaa | aaaaa |

| Water contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com