Production method of ultra-high strength toughness ductile iron crankshaft with pearlite matrix

A technology of ultra-high-strength, ductile iron, applied in the direction of casting mold, casting mold composition, casting molding equipment, etc., can solve the problems of material cost, inability to achieve organization and performance, uniformity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0071] Embodiment 1: Production of J4200 crankshaft

[0072] The weight of the part is 70Kg, the basic wall thickness is 25mm, and the external dimension is 800*250*250mm.

[0073] (1) The ratio of the main charge of the original molten iron is: Q10 low-sulfur and low-titanium pig iron 20%, carbon steel scrap 55%, pearlite ductile iron 25%, and the composition of molten iron is adjusted to C: 3.83%, Si: 0.74% , Mn: 0.44%, Cu: 0.48%, Ti: 0.036%, S: 0.012%.

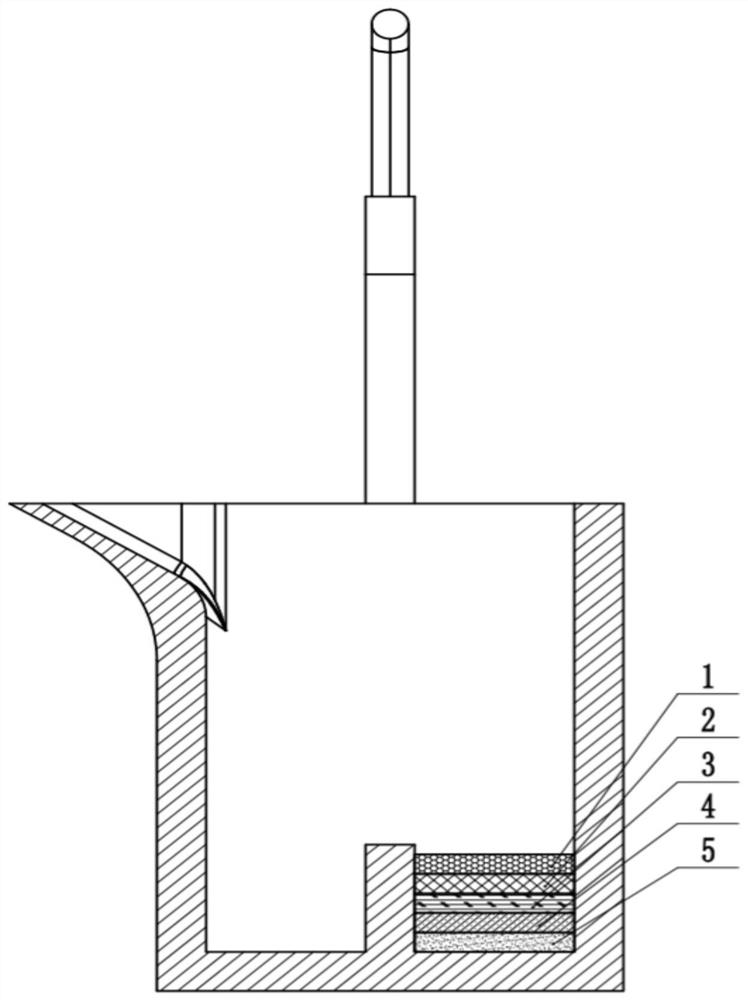

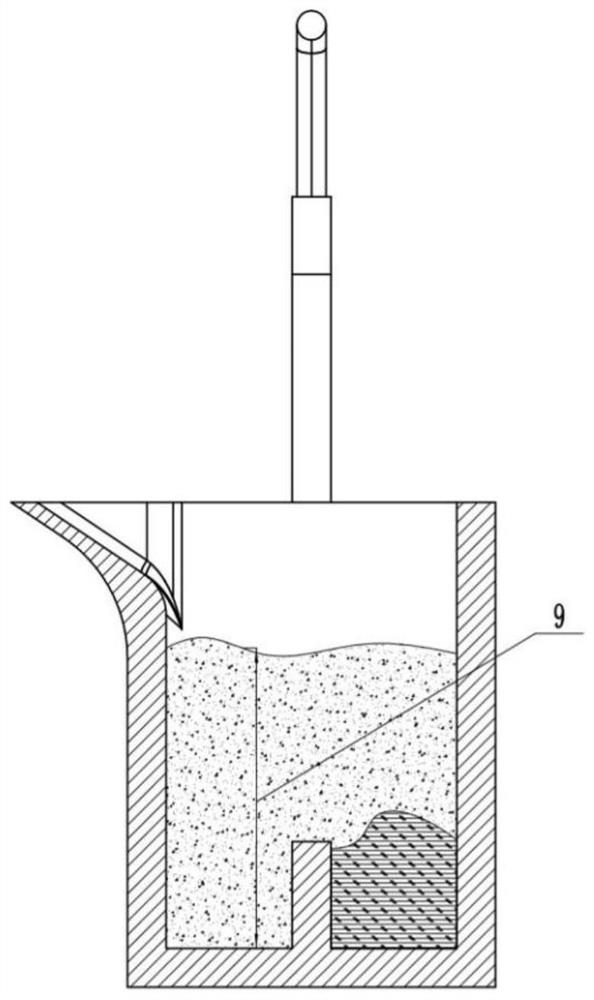

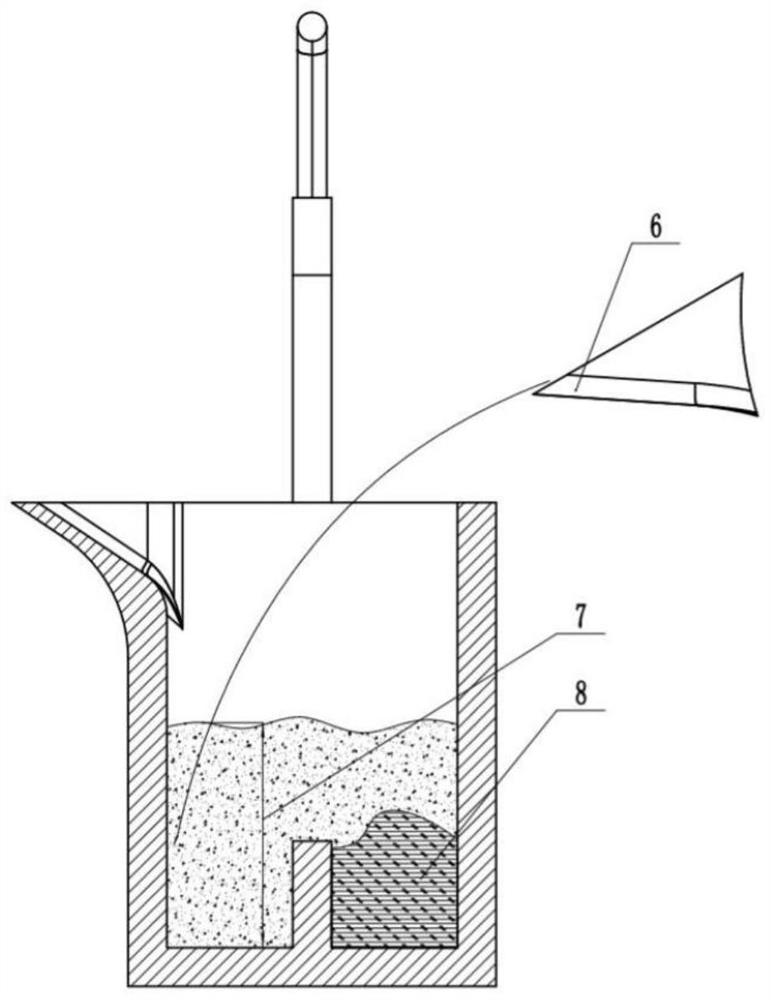

[0074] (2) The tapping weight is 550 kg, add 5.23 kg of 1-6 nodulizer (accounting for 0.95% of the weight of molten iron), 0.29% of BS-1A inoculant and 0.23% of BS-1Sb inoculant in the nodulizing bag , 0.08% SiCaMn deoxidizer and 0.4% 75 ferrosilicon, according to figure 1 According to the order of packing, according to the iron tapping speed of 500 kg / 10 seconds, pour into the spheroidizing bag, and obtain the final molten iron residual magnesium as 0.037%, rare earth: 0.007% (rare earth / magnesium=1 / 5.3).

[0075] (3) T...

Embodiment 2

[0080] Example 2: Production of JX400 crankshaft

[0081] The weight of the part is 45Kg, the basic wall thickness is 25mm, and the external dimension is 680*250*250mm.

[0082] (1) The ratio of the main charge of the original molten iron is: Q10 low-sulfur and low-titanium pig iron 20%, carbon steel scrap 55%, pearlite ductile iron 25%. The composition of molten iron is adjusted as C: 3.86%, Si: 0.70%, Mn: 0.42%, Cu: 0.5%, Ti: 0.035%, S: 0.012%.

[0083] (2) The tapping weight is 500 kg, add 4.75 kg of 1-6 nodulizer (accounting for 0.95% of the weight of molten iron), 0.28% of BS-1A inoculant and 0.22% of BS-1Sb inoculant in the nodulizing bag , 0.08% SiCaMn deoxidizer and 0.4% 75 ferrosilicon, according to iron tapping speed 500 kg / 10 seconds, pour into the spheroidizing bag, obtain final molten iron residual magnesium is 0.038%, rare earth: 0.007% (rare earth / magnesium=1 / 5.4).

[0084] (3) The spheroidized molten iron is poured into the JX400 crankshaft mold, and a 0.15...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com