Positive plate for high-capacity battery, preparation method and high-capacity battery

A positive plate and large-capacity technology, which is applied in the direction of battery electrodes, lead-acid battery electrodes, electrode carriers/collectors, etc., can solve the problems that are difficult to achieve deep discharge capacity, rapid recovery ability, high-strength starting ability, and general performance. Improve charge acceptance and discharge capacity, excellent performance, and uniform internal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

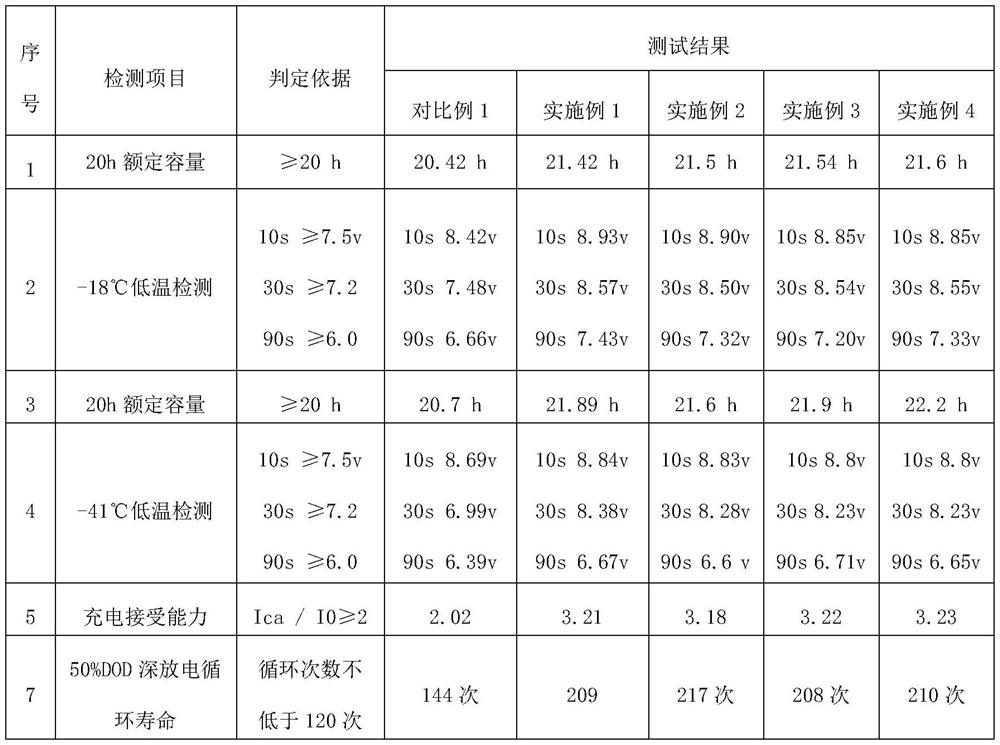

Embodiment 1

[0046] 1. Positive grid production:

[0047] The content of each component of the positive grid is: 1.2wt% tin; 0.05wt% calcium; 0.01wt% aluminum; 0.3wt% antimony; 0.03wt% iridium; The grid adopts punched plate or cast plate.

[0048] Negative grid production:

[0049] The content of each component of the negative grid is 1.2wt% tin Sn; 0.03wt% calcium Ca, and the balance is lead. The negative grid adopts stamped or cast pole plates.

[0050] 2. Production of positive lead paste:

[0051] The content of each component of the positive lead paste: magnesium lead acid 0.1kg; stannous sulfate 0.1kg; poly-1-butene 0.1kg; 4BS seed crystal 0.1kg; dilute sulfuric acid) 9kg (density 1.4g / cm 3 ); 10kg of pure water; the balance is lead powder with an oxidation degree of 71-73%.

[0052] And paste process:

[0053] (1) Mix the formula polyolefin and sodium perborate and stir, keep the temperature, and stir at a high speed of 2500r / min for 60min, then cool to normal temperature for us...

Embodiment 2

[0078] Only the differences from the above-mentioned embodiment 1 will be described below.

[0079] In this embodiment, the components of the positive grid are: 1.5wt% tin; 0.07wt% calcium; 0.02wt% aluminum; 0.5wt% antimony; 0.05wt% iridium;

[0080] The content of each component of the positive lead paste: magnesium lead acid 0.1kg; stannous sulfate 0.1kg; polybutene 0.1kg; 4BS seed crystal 0.1kg; sodium perborate 0.01kg; Density 1.4g / cm 3 ); 10kg of pure water; the balance is lead powder with an oxidation degree of 71-73%.

[0081] In this embodiment, the thickness of the tabs and the grid of the positive plate is 0.7 mm, the thickness of the positive plate is 1.2 mm; the thickness of the thick glass fiber layer is 0.3 mm, the thickness of the fine glass fiber layer is 0.3 mm, and the thickness of the PE layer is 0.2 mm. The thickness is 0.8mm, and the compression ratio is 20%.

Embodiment 3

[0083] Only the differences from the above-mentioned embodiment 1 will be described below.

[0084] In this embodiment, the contents of each component of the positive grid are: 1.2wt% tin; 0.05wt% calcium; 0.01wt% aluminum; 0.3wt% antimony; 0.03wt% iridium;

[0085] The content of each component of the positive lead paste: magnesium lead acid 0.3kg; stannous sulfate 0.3kg; polybutene 0.3kg; 4BS seed crystal 0.3kg; sodium perborate 0.03kg; Density 1.4g / cm 3 ); 12kg of pure water; the balance is lead powder with an oxidation degree of 71-73%.

[0086] In this embodiment, the thickness of the tabs and the grid of the positive plate is 0.75 mm, the thickness of the positive plate is 1.2 mm; the thickness of the thick glass fiber layer is 0.3 mm, the thickness of the fine glass fiber layer is 0.2 mm, and the thickness of the PE layer is 0.2 mm. The thickness is 0.7mm, and the compression ratio is 20%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com