High-performance power accumulator and preparation method thereof

A power type, battery technology, applied in lead-acid batteries, lead-acid battery electrodes, battery electrodes, etc., can solve the problems of low-temperature and high-current discharge of batteries, shedding of positive active materials, and low utilization of active materials, etc., to prolong life. , the effect of improving electrical conductivity and improving utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

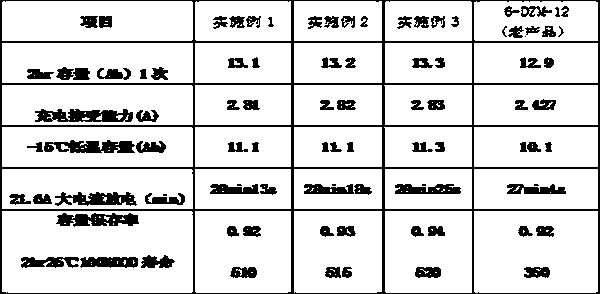

Examples

Embodiment 1

[0020] A high-performance power storage battery, including a positive plate and a negative plate,

[0021] The positive plate lead paste is prepared from the following components by weight: 1000 parts of lead powder, 100 parts of deionized water, 70 parts of sulfuric acid solution with a mass percentage concentration of 50%, 0.6 parts of polyester fiber, 4 parts of polyaniline, four alkali 8 parts of formula lead sulfate, 1 part of stannous sulfate;

[0022] The negative plate lead paste is prepared from the following components by weight: 1000 parts of lead powder, 90 parts of deionized water, 70 parts of sulfuric acid solution with a mass percent concentration of 50%, 0.6 parts of polyester fiber, 8 parts of barium sulfate, and 1 part of lignin , 0.5 parts of super carbon black.

Embodiment 2

[0024] A high-performance power storage battery, including a positive plate and a negative plate,

[0025] The positive plate lead paste is prepared from the following components by weight: 1000 parts of lead powder, 110 parts of deionized water, 90 parts of sulfuric acid solution with a concentration of 50% by mass, 0.8 parts of polyester fiber, 8 parts of polyaniline, four Basic lead sulfate 15 parts, stannous sulfate 2.3 parts;

[0026] The negative plate lead paste is prepared from the following components by weight: 1000 parts of lead powder, 110 parts of deionized water, 100 parts of sulfuric acid solution with a mass percent concentration of 50%, 0.8 parts of polyester fiber, 10 parts of barium sulfate, 2.5 parts of lignin, super Carbon black 2.2.

Embodiment 3

[0028] A high-performance power storage battery, including a positive plate and a negative plate,

[0029] The positive plate lead paste is prepared from the following components by weight: 1000 parts of lead powder, 120 parts of deionized water, 100 parts of sulfuric acid solution with a concentration of 50% by mass, 0.6-0.9 parts of polyester fiber, 4-10 parts of polyaniline 8-20 parts of tetrabasic lead sulfate, 1-3 parts of stannous sulfate;

[0030] The negative plate lead paste is prepared from the following components by weight: 1000 parts of lead powder, 95 parts of deionized water, 90 parts of sulfuric acid solution with a mass percent concentration of 50%, 0.9 parts of polyester fiber, 12 parts of barium sulfate, 3 parts of lignin, super carbon black3.

[0031] The positive and negative plate lead pastes of the above-mentioned embodiments are prepared according to the following steps respectively:

[0032] Positive plate lead paste production steps, according to th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com