Steel bar splicing sleeve screwing pipe wrench

A continuous connection and sleeve technology, applied in the direction of wrench, structural elements, building components, etc., can solve the problems of small rotation angle of the wrench, high technical proficiency requirements, and high physical strength, so as to achieve convenient clamping and loosening of workpieces. Fast, overcoming the effect of small operation space and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

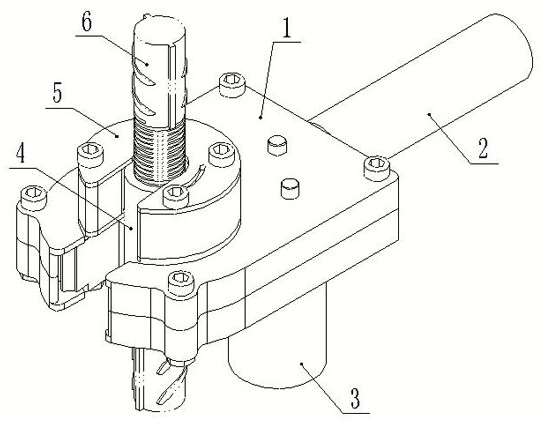

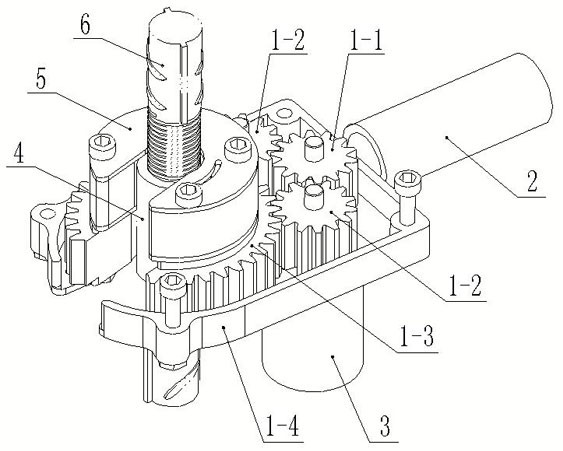

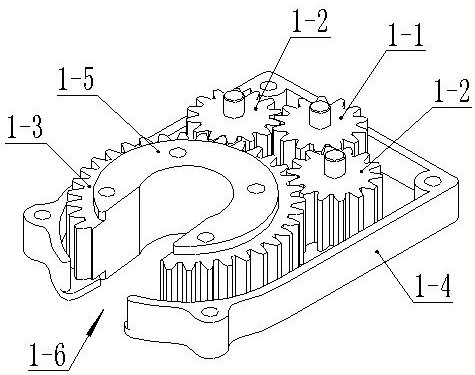

[0022] Such as Figure 1-5 As shown: the gear reducer 1 is composed of a driving gear 1-1 installed in the gear box, two idler gears 1-2 which are installed in the gear box and mesh with the driving gear, are located in the installation gear box and are connected to the gear box. The split gear 1-3 is composed of two idler gears meshing; the two ends of the split gear have bosses 1-5 in a C-shaped structure, and the outer cylindrical surfaces of the two bosses 1-5 are the same as the axis of the split gear 1-3. Shaft, and the diameter of the outer cylindrical surface of the two bosses 1-5 is smaller than the diameter of the open gear 1-3. The gear box is formed by combining and fixing the box body 1-4 and the box cover 1-8, and the corresponding positions of the box body 1-4 and the box cover 1-8 are provided with positioning round holes 1-7 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com