Clamp device for processing brake cylinder of high-speed rail train

A fixture device and brake technology, applied in positioning devices, manufacturing tools, metal processing equipment, etc., can solve the problems of high cost, high processing cost, low efficiency, etc., and achieve the effect of improving efficiency, reducing cost and improving product qualification rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

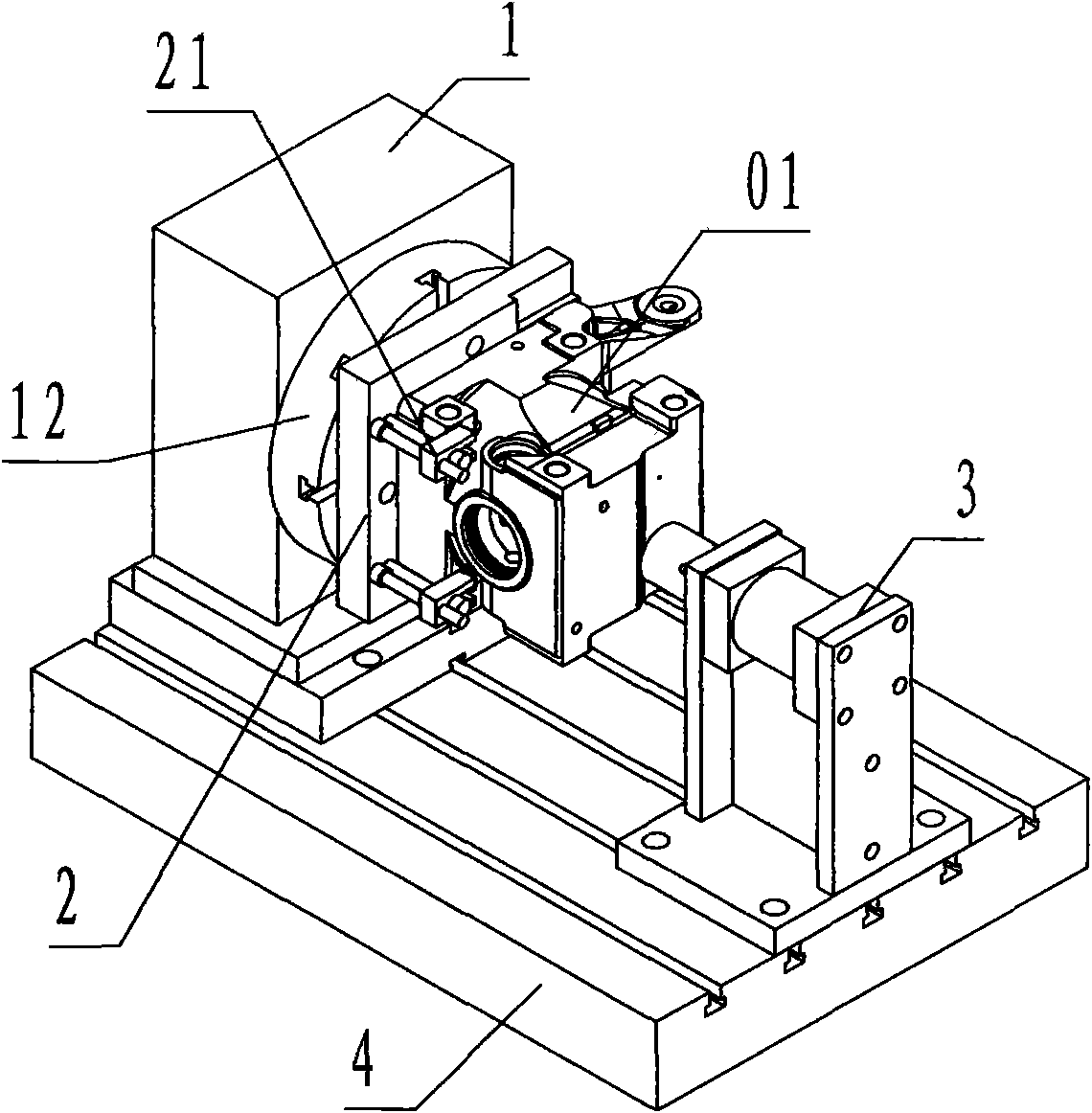

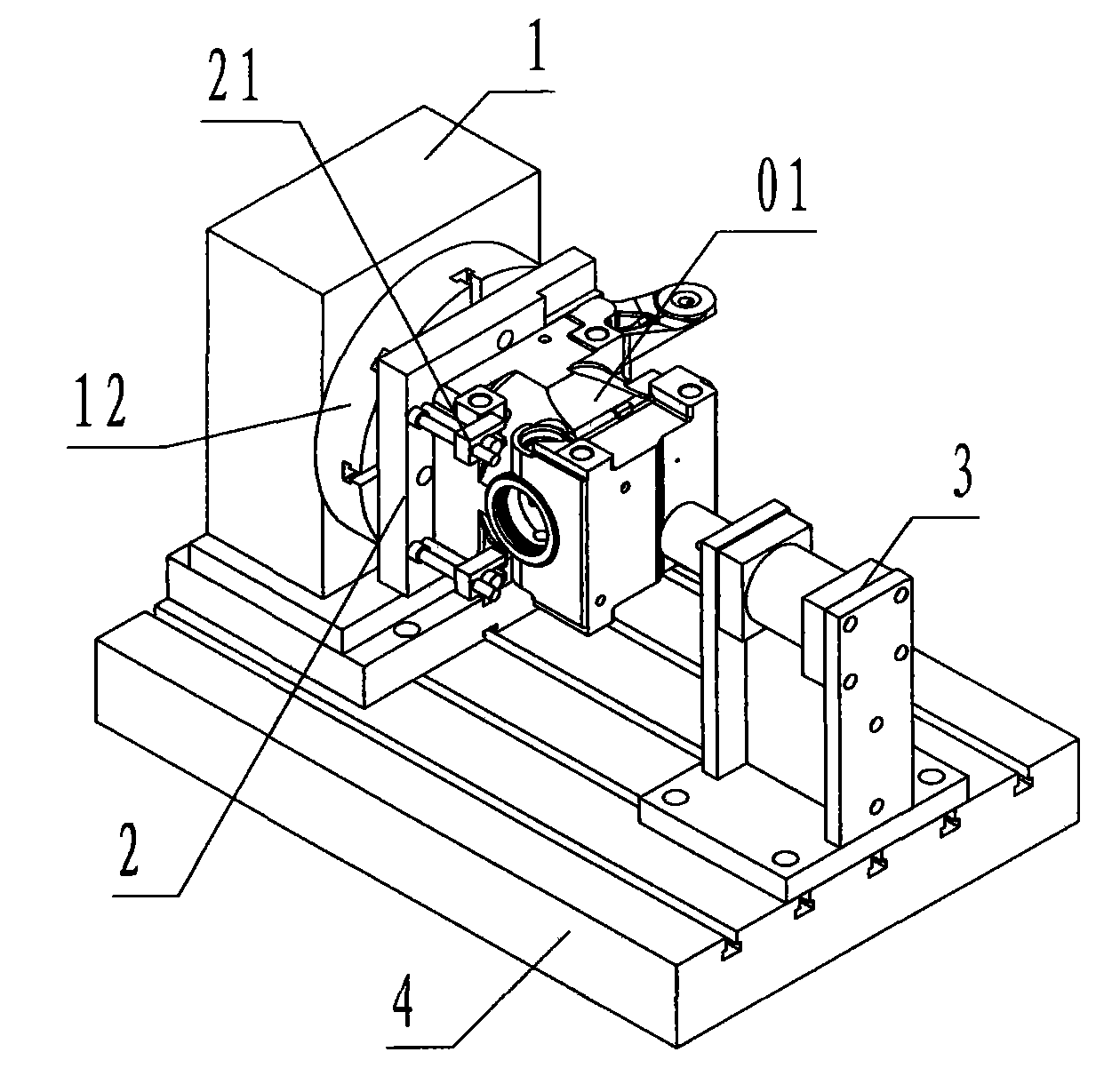

[0016] refer to figure 1 , a fixture device for processing high-speed rail brake cylinders according to the present invention includes an indexing head 1, a positioning fixture 2, a cylinder tail top 3, and a pedestal 4, wherein: the indexing head 1 is driven by a hydraulic valve and controlled For the quartering rotary indexing device of the controller of the CNC milling machine, the output end of the indexing head 1 is provided with an indexing head chuck 12;

[0017] The positioning fixture 2 is a device for clamping the workpiece 01 made of a rectangular steel plate. The back side of the positioning fixture 2 is a plane that cooperates with the indexing head chuck 12. The profiled surface and positioning pins and positioning holes, the periphery of the profiled surface is provided with a number of jaws 21 composed of bolts and pressure plates;

[0018] The tail top 3 of the cylinder is a device that fixes a pneumatic cylinder on a steel support, the cylinder body of the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com