Polyolefin gas pipe and performance detection device thereof

A technology of polyolefin and gas pipes, which is applied in measuring devices, liquid tightness measurement using liquid/vacuum degree, and chemical analysis using combustion, etc. It can solve the problems of difficult capture, easy stress, and easy scratching of gas pipes and other issues, to achieve the effect of improving sensitivity, increasing the scope of use, and facilitating transportation and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

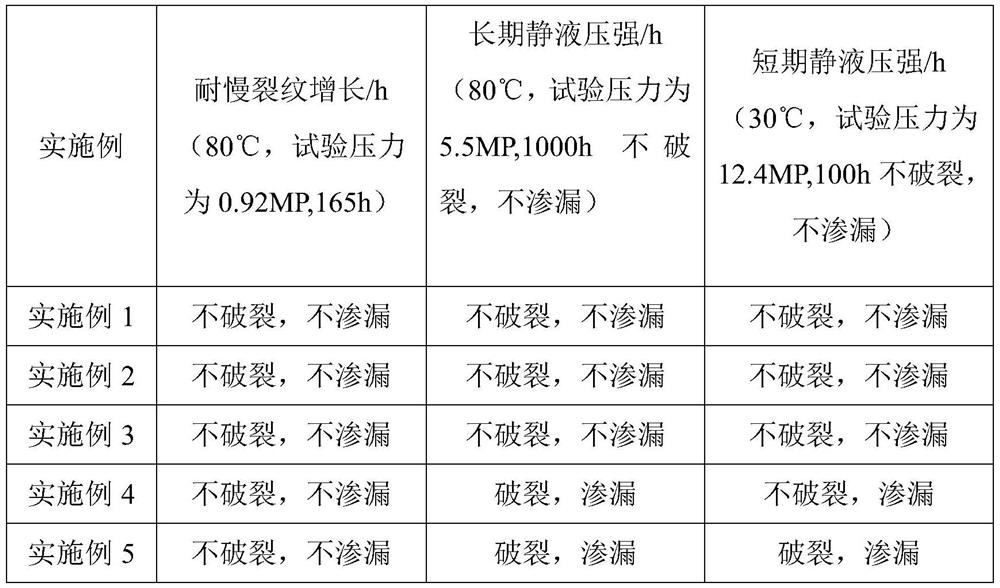

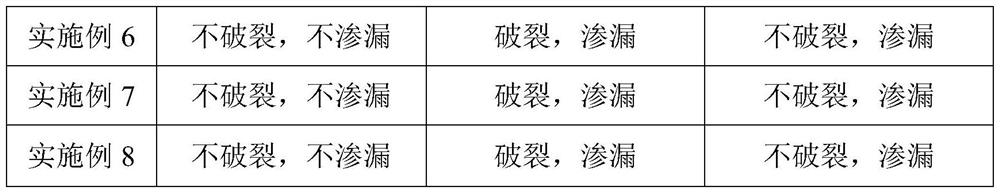

Examples

preparation example Construction

[0049] A second aspect of the present invention provides a method for preparing the polyolefin gas pipe, the steps at least comprising:

[0050] (1) Mixing: Mix the above raw materials to obtain a pipe premix; (2) Granulation: Granulate the pipe premix and cool to obtain a granular pipe mixture; (3) Forming: Extrude the granular pipe mixture Forming, traction, cooling, that is.

[0051] The preparation method of the polyolefin gas pipe described in the present invention is not particularly limited, and generally the preparation methods well known in the art are applicable to the preparation of the polyolefin gas pipe.

[0052] In some preferred embodiments, the steps of the preparation method of polyolefin gas pipes include at least: (1) mixing: mixing the above-mentioned raw materials into a kneader, setting the temperature at 80-90°C, and stirring Heating and mixing to obtain the pipe premix; (2) Granulation: put the pipe premix into a granulator for granulation, and cool t...

Embodiment 1

[0062] A polyolefin gas pipe, the raw materials include the following in parts by weight: 110 parts of polyolefin, 3 parts of polymer wax powder, 2 parts of vinyl silane compound, 0.8 part of composite flame retardant, and 0.3 part of antioxidant.

[0063] The polyolefin is a combination of HDPE and LLDPE, and the weight ratio between HDPE and LLDPE is 3:1. The density of the HDPE is 0.945g / cm 3 ; Melt flow index at 190° C. / 5.0 kg is 0.8 g / 10 min, purchased from HDPE (high density polyethylene) A 4062R 62429 / Saudi sabic. The melt flow index of the LLDPE at 190°C / 5.0kg is 2g / 10min; the density is 0.911g / cm 3 , purchased from LLDPE (Linear Low Density Polyethylene) LA-25 / Daelim, Korea.

[0064] Described polymer wax powder is PTFE modified polyethylene homopolymer wax powder, purchased from American Honeywell brand, model is 3405. The vinylsilane compound is vinyltris(2-methoxyethoxy)silane.

[0065] The vinyl silane compound also includes a grafting initiator and a tin-ba...

Embodiment 2

[0070] A polyolefin gas pipe, the raw materials include the following in parts by weight: 95 parts of polyolefin, 2 parts of polymer wax powder, 1 part of vinyl silane compound, 0.5 part of composite flame retardant, and 0.1 part of antioxidant.

[0071] The polyolefin is a combination of HDPE and LLDPE, and the weight ratio between HDPE and LLDPE is 2:1. The density of the HDPE is 0.947g / cm 3 ; Melt flow index at 190° C. / 5.0 kg is 0.7 g / 10 min, purchased from HDPE (High Density Polyethylene) XRT 70 / French Total. The melt flow index of the LLDPE at 190°C / 5.0kg is 0.5g / 10min; the density is 0.915g / cm 3 , purchased from LLDPE518N / SAABIC.

[0072] Described polymer wax powder is PTFE modified polyethylene homopolymer wax powder, purchased from American Honeywell brand, model is 3205B. The vinylsilane compound is vinyltrimethoxysilane.

[0073] The vinyl silane compound also includes a grafting initiator and a tin-based catalyst; the amount of the grafting initiator is 10% o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com