Desulfurization process of high-sulfur petroleum coke

A desulfurization process and petroleum coke technology, which is applied in the coking field, can solve the problems of high desulfurization cost, complex process, and many equipment, and achieve the effects of reducing environmental pollution, simple preparation and low price.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

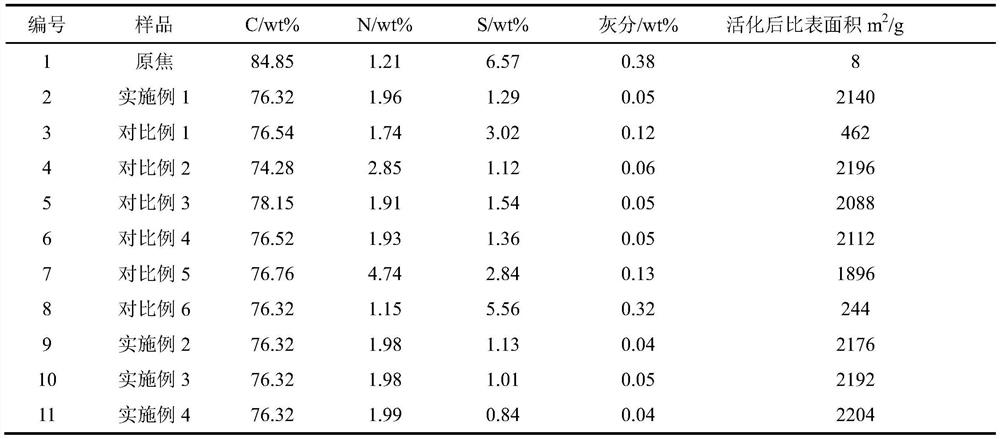

Examples

Embodiment 1

[0047] The improved high-sulfur petroleum coke desulfurization process is used to achieve the purpose of producing low-sulfur petroleum coke. The specific steps are as follows:

[0048] The preparation mass fraction is 2% Ca(OH) 2 solution, the Ca(OH) 2 The solution and high-sulfur petroleum coke were added into the autoclave according to the liquid-solid ratio of 5:1, the temperature was kept at 90°C, the activation time was 4h, and the pressure in the autoclave was 40MPa. After the activation process, the solution was suction-filtered, and the activated Petroleum coke was dried at 110°C for 10 hours.

[0049] Prepare 8mol / L HNO 3 with 2mol / L H 2 o 2 The mixed solution is used as an oxidant, and then NiO, CrCO 3 The mixed solid with CaO mass ratio=1:0.3:3 is used as catalyst.

[0050] The oxidant and the activated high-sulfur petroleum coke are mixed according to the liquid-solid ratio of 10:1, and the catalyst and the activated high-sulfur petroleum coke are mixed acco...

Embodiment 2

[0082] The improved high-sulfur petroleum coke desulfurization process is used to achieve the purpose of producing low-sulfur petroleum coke. The specific steps are as follows:

[0083] The preparation mass fraction is 2% Ca(OH) 2 solution, the Ca(OH) 2 The solution and high-sulfur petroleum coke were added into the autoclave according to the liquid-solid ratio of 5:1, the temperature was kept at 90°C, the activation time was 4h, and the pressure in the autoclave was 40MPa. After the activation process, the solution was suction-filtered, and the activated Petroleum coke was dried at 110°C for 10 hours.

[0084] Prepare 9mol / L HNO 3 with 3mol / L H 2 o 2 The mixed solution is used as an oxidant, and then NiO, CrCO 3 The mixed solid with CaO mass ratio=1:0.3:3 is used as catalyst.

[0085] The oxidant and the activated high-sulfur petroleum coke are mixed according to the liquid-solid ratio of 10:1, and the catalyst and the activated high-sulfur petroleum coke are mixed acco...

Embodiment 3

[0088] The improved high-sulfur petroleum coke desulfurization process is used to achieve the purpose of producing low-sulfur petroleum coke. The specific steps are as follows:

[0089] The preparation mass fraction is 2% Ca(OH) 2 solution, the Ca(OH) 2 The solution and high-sulfur petroleum coke were added into the autoclave according to the liquid-solid ratio of 5:1, the temperature was kept at 90°C, the activation time was 4h, and the pressure in the autoclave was 40MPa. After the activation process, the solution was suction-filtered, and the activated Petroleum coke was dried at 110°C for 10 hours.

[0090] Prepare 9mol / L HNO 3 with 3mol / L H 2 o 2 The mixed solution is used as an oxidant, and then NiO, CrCO 3 The mixed solid with CaO mass ratio=1:0.25:2.5 is used as catalyst.

[0091] The oxidant and the activated high-sulfur petroleum coke are mixed according to the liquid-solid ratio of 10:1, and the catalyst and the activated high-sulfur petroleum coke are mixed a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com