A fiber insulation riser material for casting

A technology for thermal insulation risers and fibers, which is applied to casting molding equipment, molds, mold components, etc., can solve the problems of decreased thermal insulation effect, loss of thermal insulation effect, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

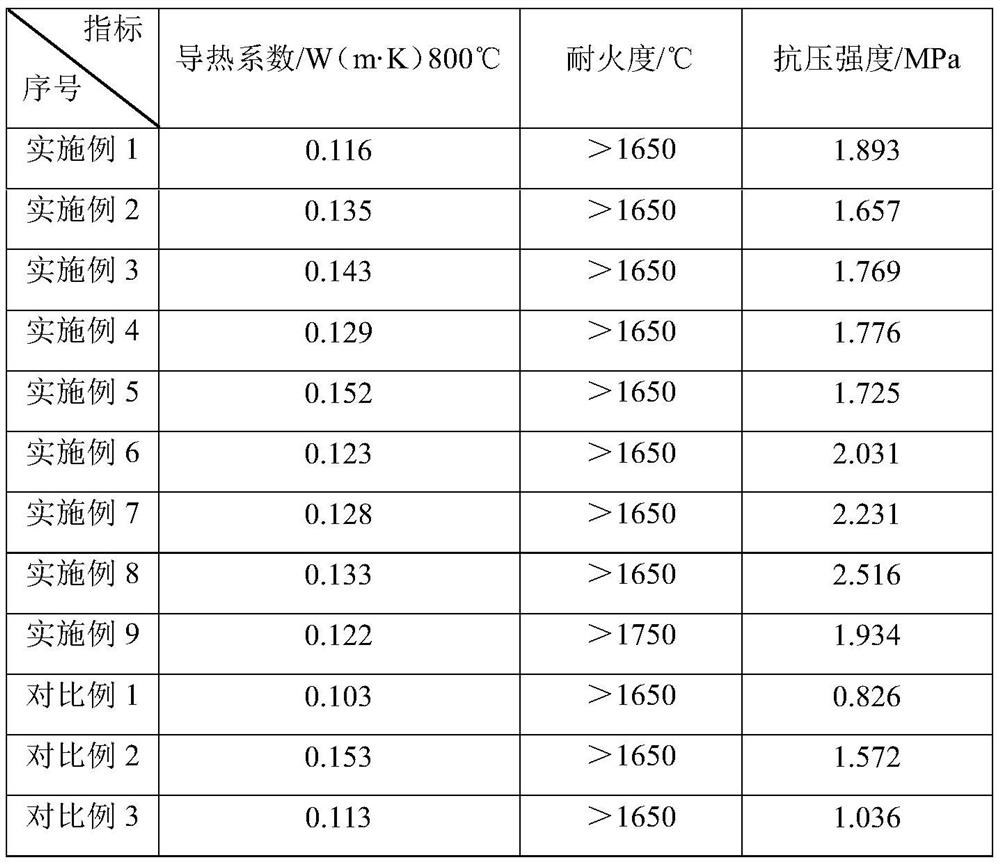

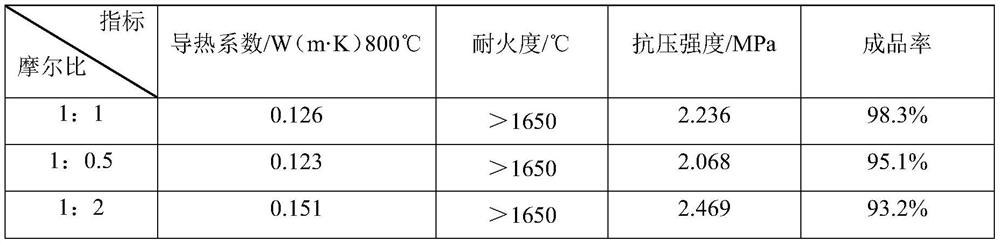

Examples

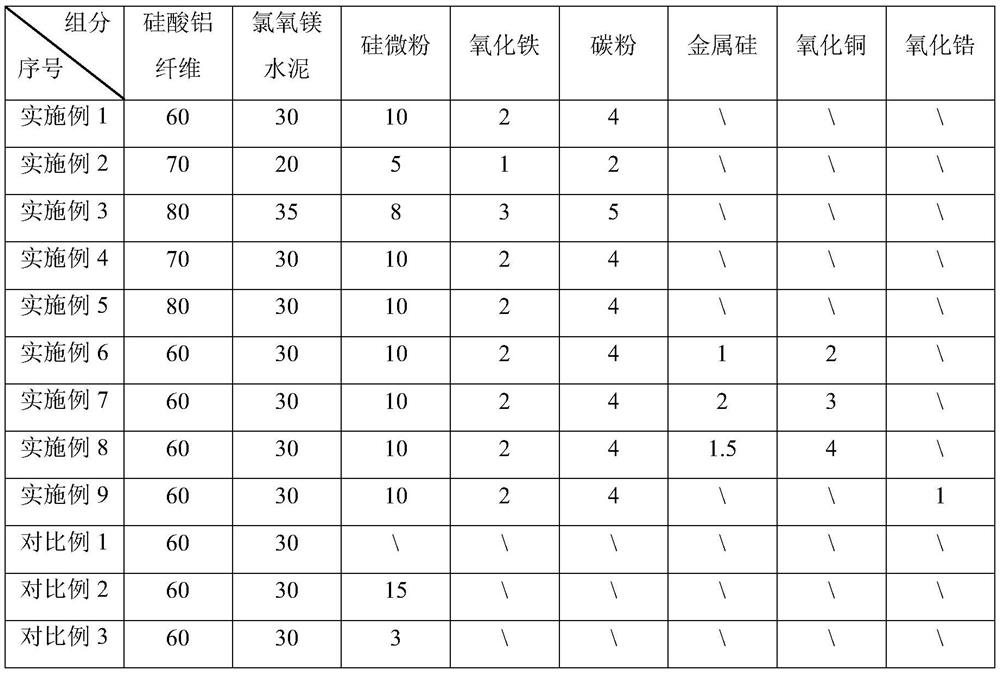

Embodiment 1

[0024] The fiber insulation riser material for casting of the present embodiment comprises the following components in parts by weight:

[0025] 60 parts of aluminum silicate fiber, 30 parts of magnesium oxychloride cement containing calcium oxide, 10 parts of silicon micropowder, 2 parts of iron oxide, and 4 parts of carbon powder.

[0026] Among them, magnesium oxychloride cement containing calcium oxide, commonly known as Sorel cement, has good fire resistance and low thermal conductivity. The main raw materials are light-burned magnesium and magnesium chloride, which form MgO-MgCl in aqueous solution. 2 -H 2 O ternary reaction system. The main product has four crystal phases: 2MgO MgCl 2 ·8H 2 O, 3MgO MgCl 2 ·8H 2 O, 5MgO MgCl 2 ·8H 2 O and 9MgO·MgCl 2 ·8H 2 O.

[0027] The lightly burned magnesia of the present embodiment adopts magnesite, and the 120-mesh sieve is taken as the material (not limited to 120 mesh, as long as the fineness of magnesite is greater th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com