Forming mold for casting of integrated floating plate

A technology for forming molds and floating plates, which is applied to forming tools, manufacturing tools, metal processing equipment, etc., can solve the problems of easy shaking and affect the forming effect of sheets, and achieve the effect of ensuring the positioning effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

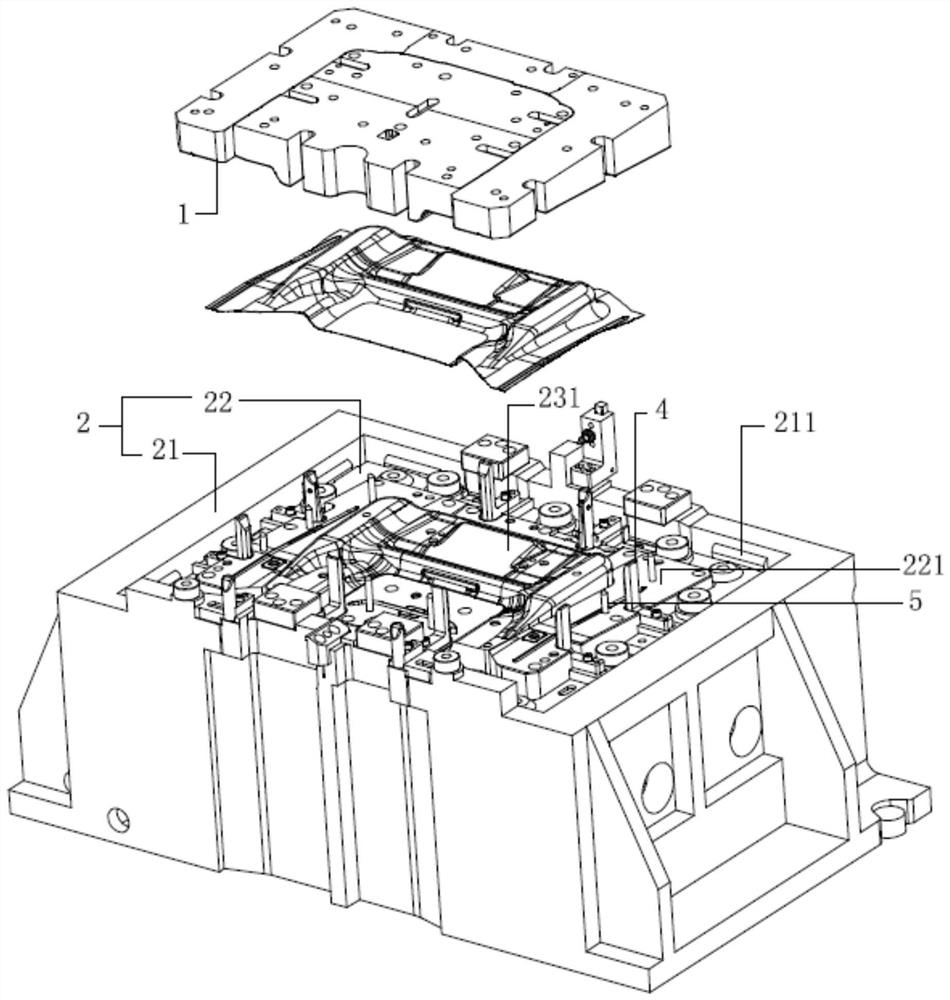

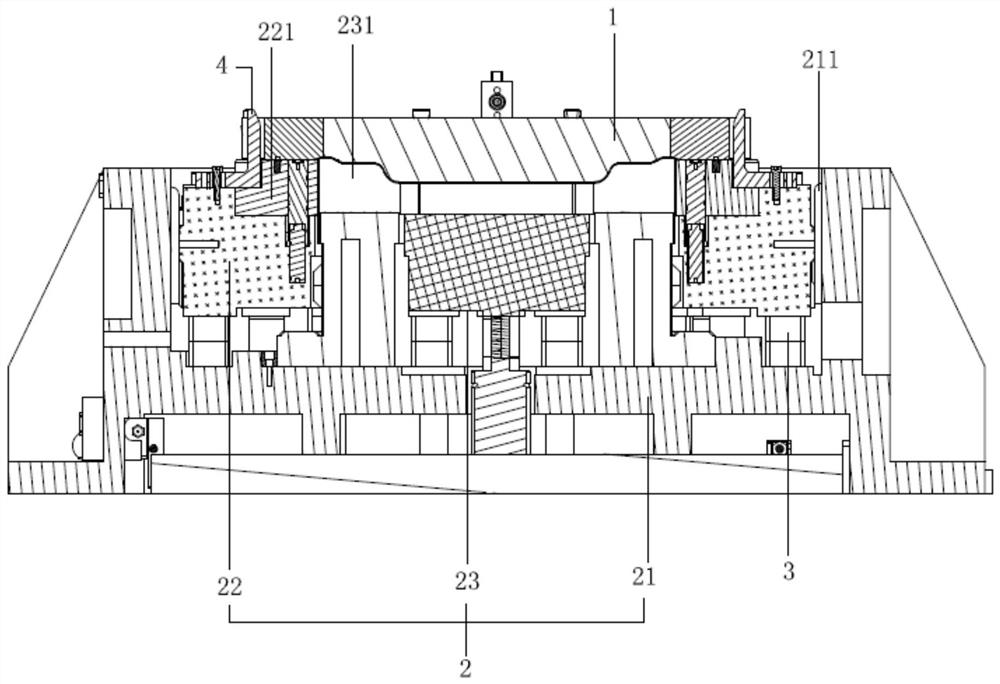

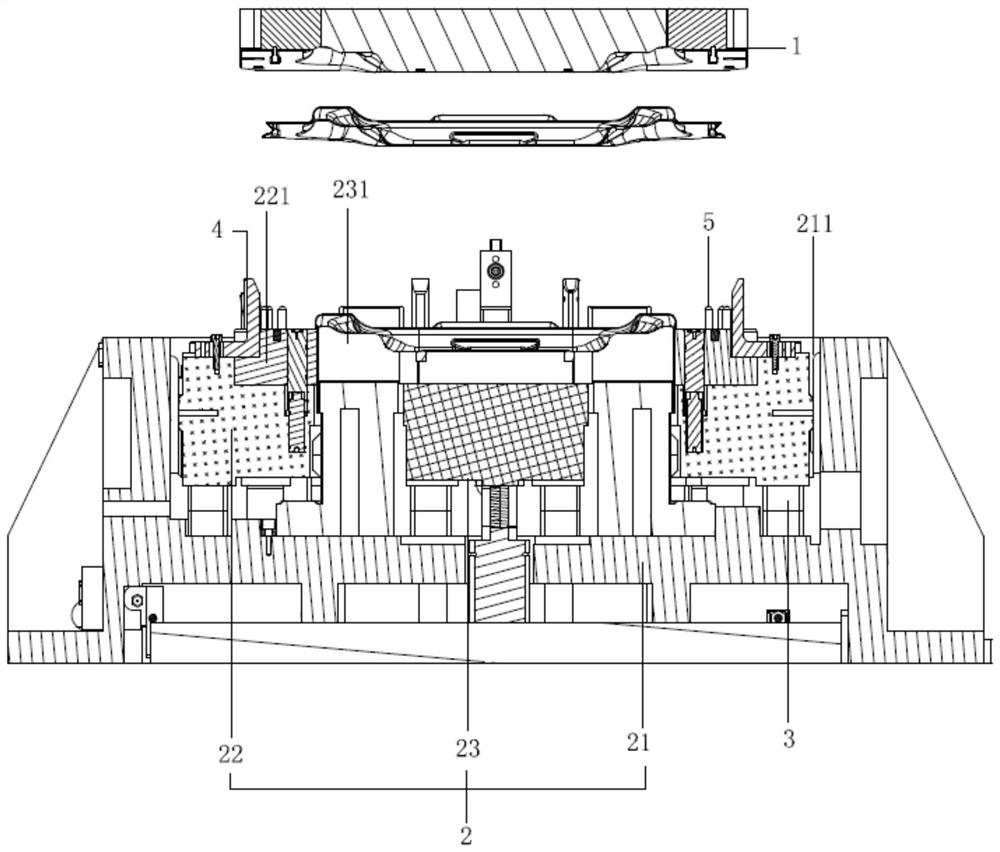

[0024] see Figure 1 to Figure 4 , the figure shows a casting overall floating plate forming die provided by Embodiment 1 of the present invention, including:

[0025] The upper mold mechanism includes an upper forming plate 1, and the bottom of the upper forming plate 1 is provided with an upper forming surface;

[0026] The lower mold mechanism 2 includes a lower mold base 21 and an integral floating plate 22, the lower mold base 21 is provided with a mounting seat 23, the top of the mounting base 23 is provided with a lower forming plate 231, and the bottom of the integral floating plate 22 is fixed by a floating member 3 Installed in the lower mold base 21 , and the integral floating plate 22 is sheathed on the mounting base 21 , the integral floating plate 22 is provided with second forming plates 221 symmetrically arranged on both sides of the lower forming plate 231 .

[0027] Specifically, see Figure 1 to Figure 4 , The floating part 3 is an oil pressure buffer.

...

Embodiment 2

[0033] see Figure 1 to Figure 4 , the figure shows an integral floating plate forming mold for castings provided by Embodiment 2 of the present invention. On the basis of the above embodiments, this embodiment further makes the following technical solutions as improvements: the limit block 4 The structure is L-shaped, and the limit block 4 includes a fixed rod 41 and a limit rod 42. One end of the fixed rod 41 is fixedly installed on the integral floating plate 22, and the other end is clamped in the groove on the second forming plate 221. The position rod 42 is perpendicular to the fixed rod 41 ; the end of the limit rod 42 is provided with a slope; the fixed rod 41 is provided with a waist-shaped hole 411 and a circular hole 412 .

[0034] When the limit block is clamped by the upper mold mechanism and the lower mold mechanism, the limit rod is clamped in the corresponding groove on the upper forming plate to ensure the accuracy of mold clamping. The end of the limit rod i...

Embodiment 3

[0036] see Figure 1 to Figure 4 , the figure shows an integral floating plate molding die for castings provided by Embodiment 3 of the present invention. On the basis of the above embodiments, this embodiment further makes the following technical solutions as improvements: the lower mold base 21 Protruding blocks 211 are provided on the four inner sidewalls.

[0037] Protrusions are arranged on the four inner sidewalls of the lower mold base, and the positions of the protrusions on the opposite inner sidewalls are symmetrical, and when the integral floating plate moves up and down, its shaking is restricted.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com