Battery module, power battery pack and vehicle

A battery module and module technology, applied in the field of vehicles, can solve the problems of small exhaust aperture of the exhaust pipe 100, thermal runaway of a single battery, long exhaust path of the exhaust pipe 100, etc., to reduce the probability of fire and explosion , to avoid the effect of further temperature rise and further increase of internal pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] Specific embodiments of the present disclosure will be described in detail below in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to illustrate and explain the present disclosure, and are not intended to limit the present disclosure.

[0047] In this disclosure, unless stated to the contrary, the used orientation words such as "upper and lower" generally have the same meaning as upper and lower when the vehicle is running normally, and "inner and outer" are the outlines of related parts inside and outside.

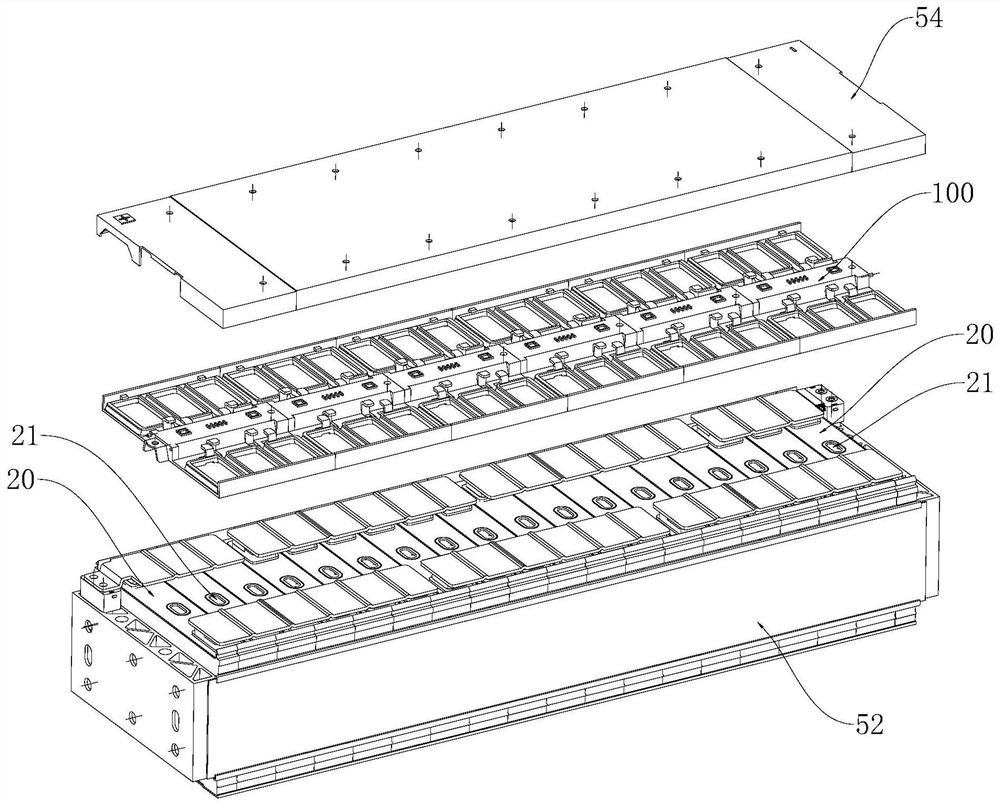

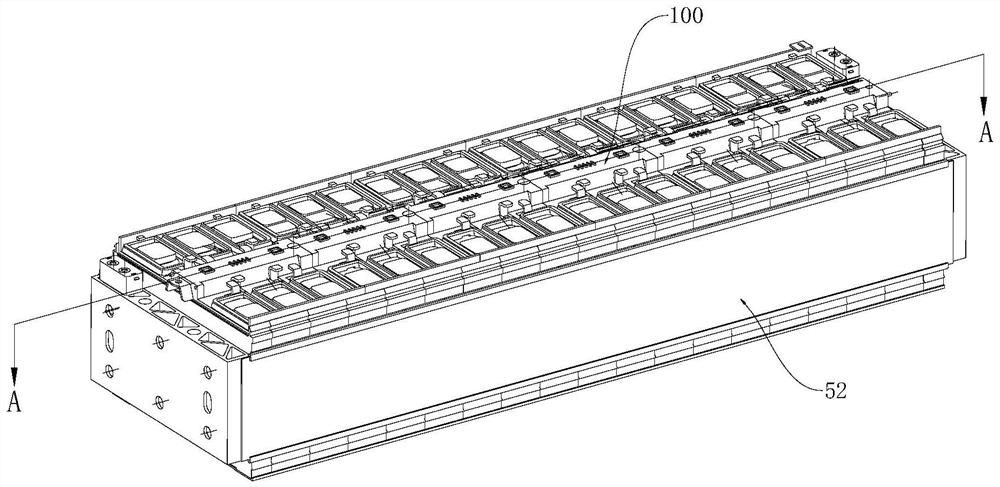

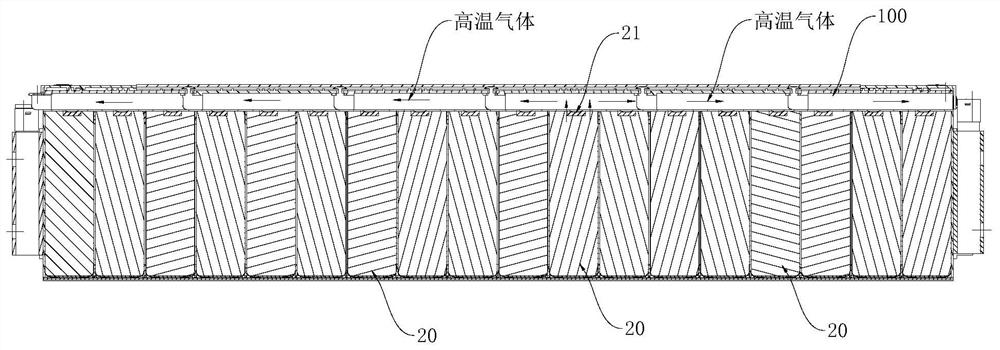

[0048] like Figure 4 to Figure 8 As shown, according to one aspect of the present disclosure, a battery module is provided. The battery module includes a module end cover, a plurality of single cells 20 and a cell protection cover 10. The holes 30 and the vent holes 30 are arranged opposite to the explosion-proof valve 21 on the single battery 20 and correspond to each other. The air...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com