Preparation method of aluminum phosphite

A technology of aluminum phosphite and phosphorous acid, applied in the field of flame retardant, can solve the problems of inability to adapt to large-scale industrial production, long production time, damage to equipment, etc., and achieve the effects of low cost, high production efficiency and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

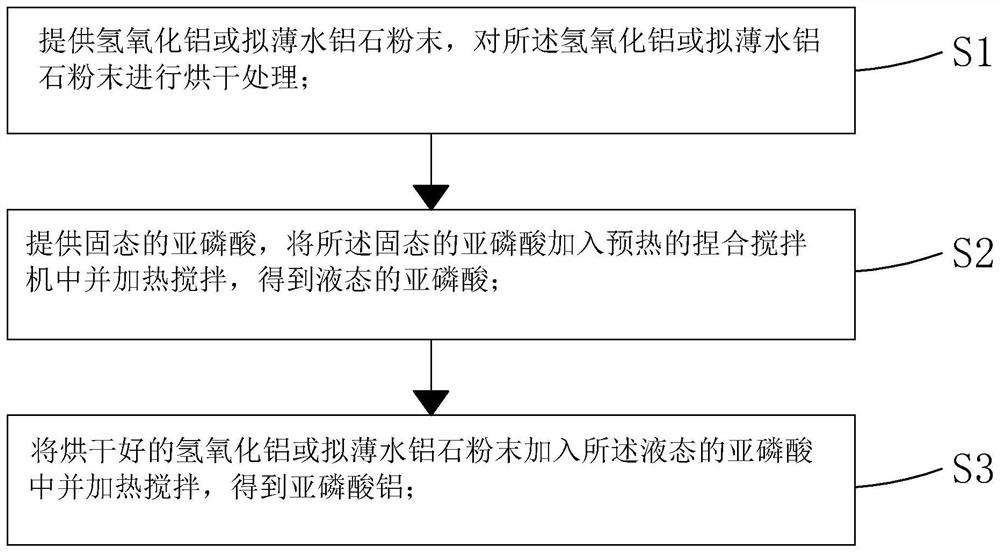

[0035] see figure 1 , the invention provides a kind of preparation method of aluminum phosphite, comprises the steps:

[0036] Step S1, providing aluminum hydroxide or pseudo-boehmite powder, and drying the aluminum hydroxide or pseudo-boehmite powder.

[0037] Specifically, the step S1 specifically includes: drying the aluminum hydroxide or pseudo-boehmite powder in an oven at 110-130° C. for 4-8 hours.

[0038] Further, in the step S1, the moisture content of the dried aluminum hydroxide or pseudo-boehmite powder is controlled at 0.5%-1%.

[0039] Step S2, providing solid phosphorous acid, adding the solid phosphorous acid into a preheated kneading mixer and heating and stirring to obtain liquid phosphorous acid.

[0040] Specifically, the step S2 specifically includes: adding the solid phosphorous acid into a preheated kneading mixer, heating and stirring to melt the solid phosphorous acid, continuing to heat and stir to raise the temperature to 100-120°C, and Stirring w...

Embodiment 1

[0058] Weigh 1600g of aluminum hydroxide and place it in an oven at 180° C. for drying for 6 hours. The moisture content of aluminum hydroxide is 0.8%, and it is ready for use after cooling.

[0059] Weigh 2600g of solid phosphorous acid into the preheated kneading mixer, heat and stir to melt the phosphorous acid, continue stirring to raise the temperature to 130°C, and pass nitrogen protection during the heating and stirring process to prevent oxidation.

[0060] Slowly add the dried aluminum hydroxide into phosphorous acid in batches, and heat to 150°C while stirring. After 3 hours of reaction, after obtaining a powdery product, raise the temperature to 200°C and continue stirring for 2 hours. After the reaction is complete, To generate powdered aluminum phosphite, the stirring speed needs to be controlled in a slow-fast-slow rhythm during the feeding process.

[0061] The aluminum phosphite powder formed by the reaction was slowly stirred and cooled to room temperature.

...

Embodiment 2

[0064] Weigh 1200 g of pseudo-boehmite powder and place it in an oven at 120° C. for 7 hours to dry. The moisture content of the pseudo-boehmite powder is 0.7%, and it is cooled for later use.

[0065] Weigh 2000g of solid phosphorous acid into the kneading mixer, heat and stir to melt the phosphorous acid, continue to stir and raise the temperature to 130°C, and pass nitrogen protection during the heating and stirring process to prevent oxidation.

[0066] Slowly add the dried pseudo-boehmite powder into phosphorous acid in batches, heat to 140°C while stirring, and react for 4 hours. After obtaining the powdery product, raise the temperature to 185°C and continue to stir and react for 3 hours. After completion, powdered aluminum phosphite is generated, and the stirring speed needs to be controlled in a slow-fast-slow rhythm during the feeding process.

[0067] The aluminum phosphite powder formed by the reaction was slowly stirred and cooled to room temperature.

[0068] Pu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com