Hydrophilic antigen and/or hydrophobic antigen vaccine delivery system and preparation method thereof

A delivery system and a hydrophobic technology, applied in the field of vaccine delivery system and its preparation, can solve the problems of poor lymph node targeted delivery effect and the like, and achieve the effect of a simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

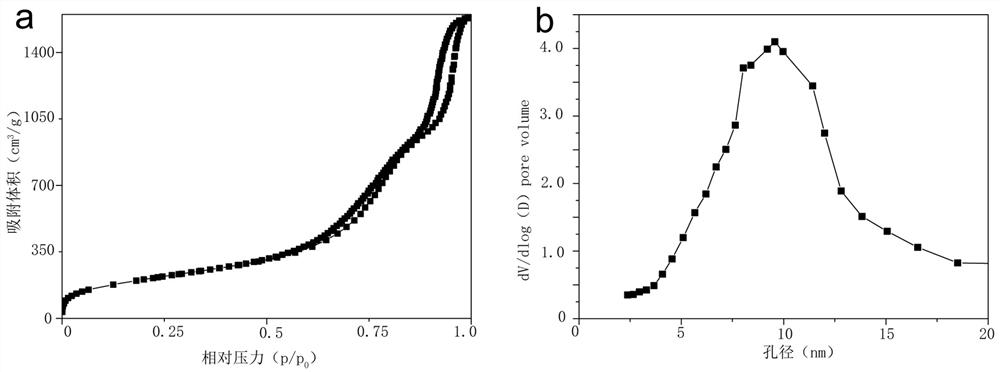

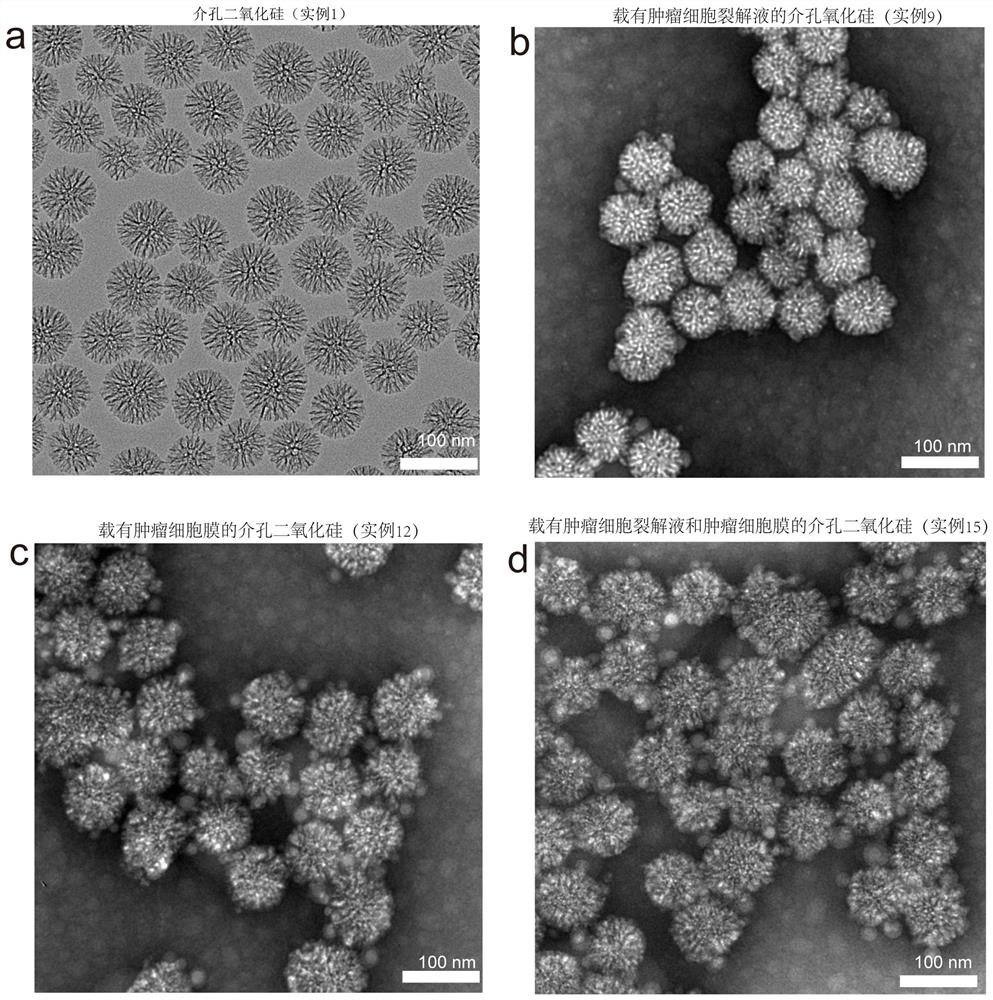

Embodiment 1

[0052] Dissolve 6 g of cetyltrimethylammonium chloride and 0.18 g of triethanolamine in sterile water, heat and stir for 1 h, add 20 ml of tetraethyl orthosilicate / cyclohexane solution (v / v, 5%), Adjust the stirring speed to 180rpm, react for 24 h, the product is generated in the water phase, the water phase is diluted with ethanol, centrifuged, and the precipitate is collected, the precipitate is washed twice with absolute ethanol, and resuspended with 40 ml of ammonium nitrate / ethanol solution (w / v, 0.6%), heated and stirred to reflux for 6 h to remove the template agent cetyltrimethylammonium chloride; the refluxed mesoporous silica was collected by centrifugation and freeze-dried.

Embodiment 2

[0054] Dissolve 6 g of cetyltrimethylammonium chloride and 0.8 g of triethanolamine in sterile water, heat and stir for 1 h, add 20 ml of tetraethylorthosilicate / naphthalene solution (v / v, 20%), and dissolve Adjust the stirring speed to 300rpm, react for 12 hours, the product is formed in the water phase, the water phase is diluted with ethanol, centrifuged, and the precipitate is collected, the precipitate is washed twice with absolute ethanol, and resuspended with 40 ml of ammonium nitrate / ethanol solution (w / v, 0.6%), heated and stirred to reflux for 6 h to remove the template agent cetyltrimethylammonium chloride; the refluxed mesoporous silica was collected by centrifugation and freeze-dried.

Embodiment 3

[0056] Dissolve 6 g of cetyltrimethylammonium chloride and 0.05 g of triethanolamine in sterile water, heat and stir for 1 h, add 20 ml of tetraethylorthosilicate / naphthalene solution (v / v, 40%), and dissolve The stirring speed was adjusted to 100 rpm, and the reaction was carried out for 1 h. The product was formed in the water phase. The water phase was diluted with ethanol, centrifuged, and the precipitate was collected. The precipitate was washed twice with absolute ethanol, and resuspended with 40 ml of ammonium nitrate / ethanol solution (w / v, 0.6%), heated and stirred to reflux for 6 h to remove the template agent cetyltrimethylammonium chloride; the refluxed mesoporous silica was collected by centrifugation and freeze-dried.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com