Instant nutritional freeze-dried noodles and preparation method thereof

A freeze-dried and nutritious technology, applied in the field of pasta, can solve the problems of easily destroying the nutrition and health of freeze-dried noodles, easy to cover up the freshness of quick-frozen noodles, and the taste of seasoning packets, etc., to enhance human immunity, increase natural pigments and vegetables and fruits Fragrance, effect of reducing growth rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0047] A method for preparing instant nutritious freeze-dried noodles comprises two parts: preparing quick-frozen cooked bread and preparing seasoning soup packets.

[0048] Described preparation quick-frozen cooked bread, comprises the following steps:

[0049] 1.1) Prepare mixed flour

[0050] Weigh wheat flour, corn flour, black sesame powder, fish bone meal, modified protein, sodium stearoyl lactylate, sodium starch phosphate and sodium tripolyphosphate according to a certain mass ratio, add them to the mixer, and stir for 30 to 60 minutes Afterwards, make mixed flour;

[0051] 1.2) Preparation of fruit and vegetable juice

[0052] Weigh kale, tomatoes, cranberries, spinach, kelp and carrots according to a certain mass ratio, wash them separately, peel and remove the core, then put them into a juicer, and add 1 / 5 times the mass of Pure water is used to squeeze the juice, and then the squeezed juice is filtered through a non-woven fabric to obtain fruit and vegetable jui...

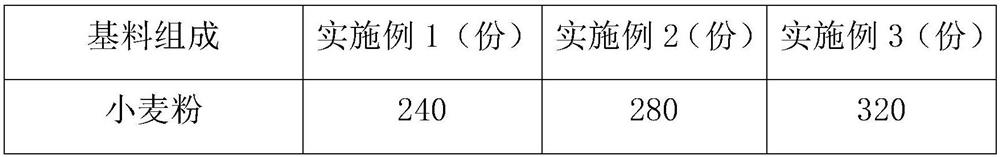

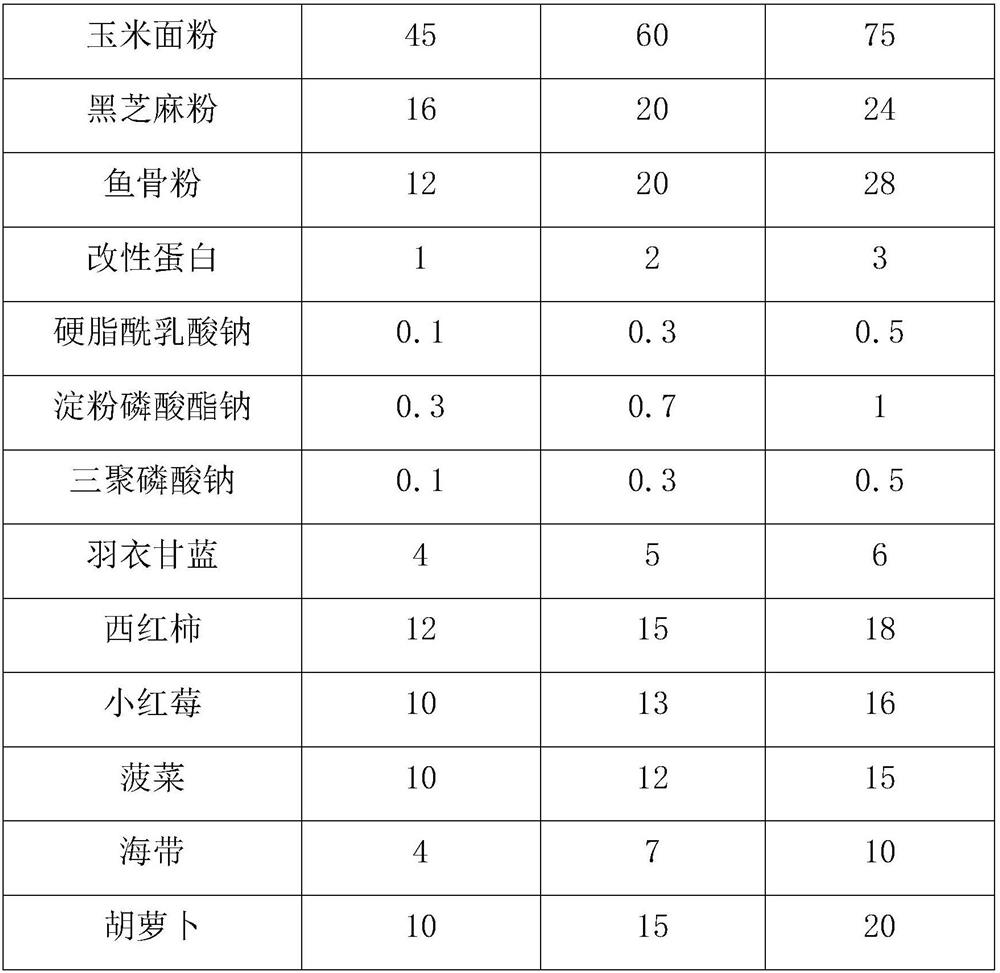

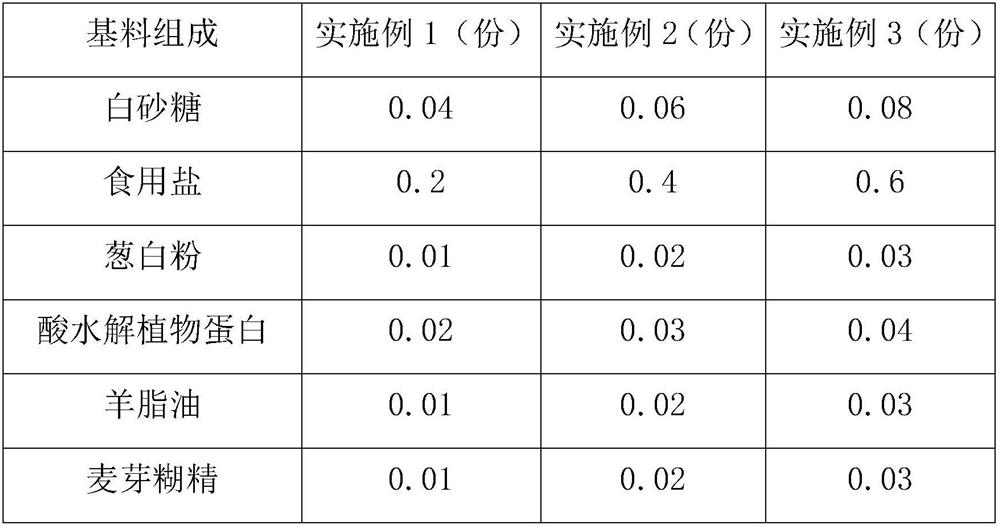

Embodiment 1

[0073] A kind of instant nutritious freeze-dried noodles, including quick-frozen cooked bread and seasoning soup bag;

[0074] The formula of quick-frozen cooked bread according to mass components is as follows: 240 parts of wheat flour, 45 parts of corn flour, 16 parts of black sesame powder, 12 parts of fish bone meal, 1 part of modified protein, 0.1 part of sodium stearoyl lactylate, 0.3 parts of sodium starch phosphate 0.1 parts of sodium tripolyphosphate, 4 parts of kale, 12 parts of tomatoes, 10 parts of cranberries, 10 parts of spinach, 4 parts of kelp and 10 parts of carrots.

[0075] Among them, the fineness of wheat flour, corn flour, black sesame powder and fish bone meal is 90 mesh, and the modified protein is modified zein alcohol protein. Put it in a 60% ethanol solution, then place it in a shaker, heat it to keep the temperature in the shaker at 50°C, shake it for 30 minutes, then carry out suction filtration, and then use the modified solution for salting-out t...

Embodiment 2

[0091] A kind of instant nutritious freeze-dried noodles, including quick-frozen cooked bread and seasoning soup bag;

[0092] The formula of quick-frozen cooked bread according to mass components is as follows: 280 parts of wheat flour, 60 parts of corn flour, 20 parts of black sesame powder, 20 parts of fish bone meal, 2 parts of modified protein, 0.3 part of sodium stearoyl lactylate, 0.7 part of sodium starch phosphate 0.3 parts of sodium tripolyphosphate, 5 parts of kale, 15 parts of tomatoes, 13 parts of cranberries, 12 parts of spinach, 7 parts of kelp and 15 parts of carrots.

[0093] Among them, the fineness of wheat flour, corn flour, black sesame powder and fish bone meal is 95 mesh, and the modified protein is modified zein alcohol protein. The preparation method is as follows: adding corn flour to the volume fraction of 8 times its total mass Put it in a 60% ethanol solution, then place it in a shaker, heat it to keep the temperature in the shaker at 55°C, shake i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com