Positive additive and preparation method and application thereof

An additive and positive electrode technology, applied in the field of positive electrode additives and its preparation, can solve the problems of inapplicability to large-scale industrial production, complex preparation process, complex synthesis process, etc., and achieve the effects of increasing irreversible capacity, simplifying the preparation process, and high charging capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

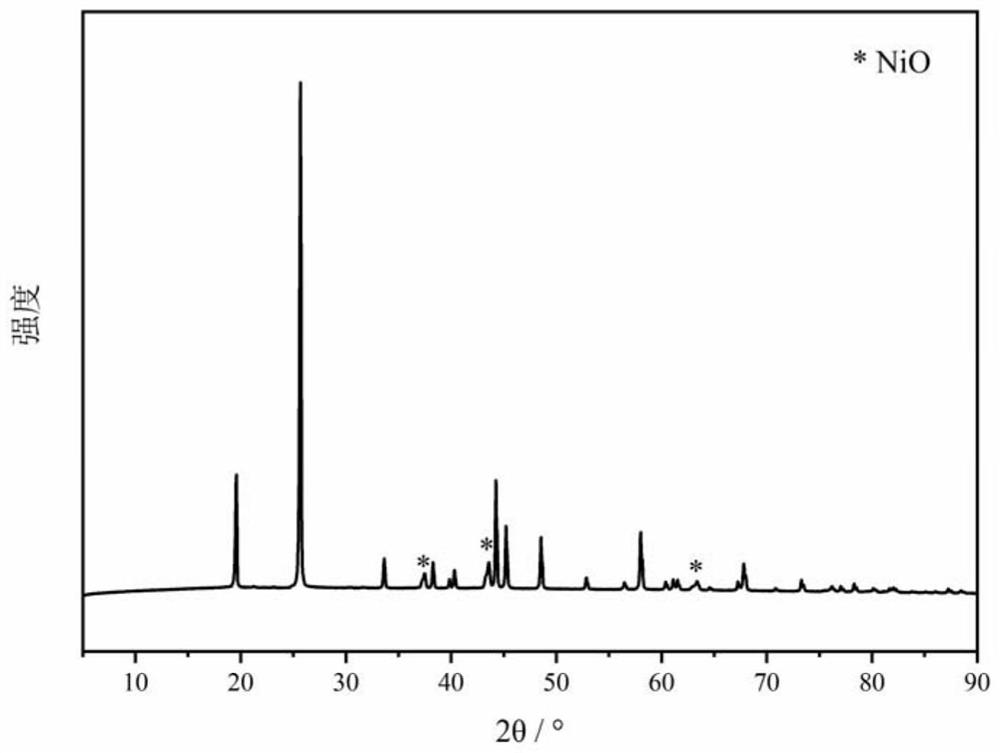

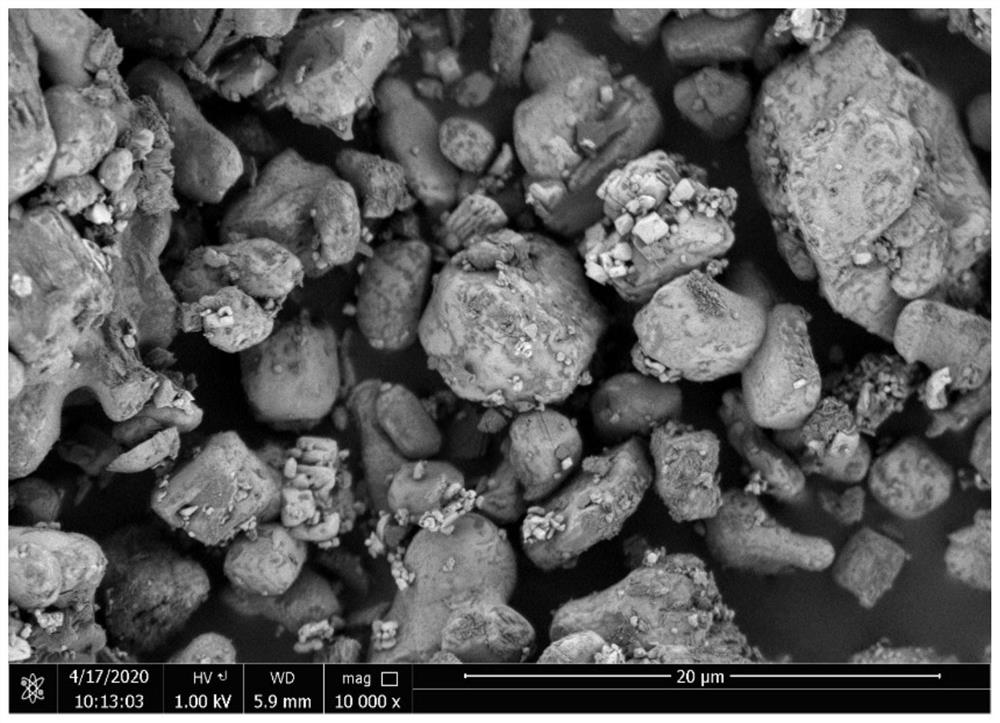

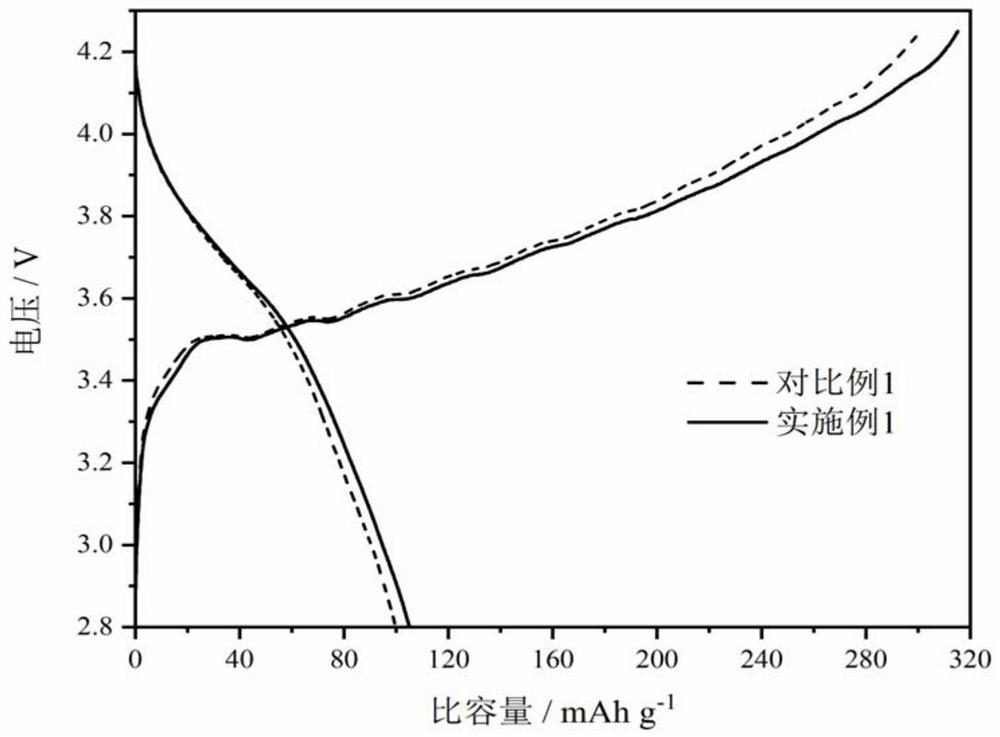

[0039] The chemical formula of the positive electrode additive of the present embodiment is Li 2 NiO 2, the particle size is D50=7.5μm, and the initial charge capacity is 332mAh / g.

[0040] The preparation method of the positive electrode additive of the present embodiment, comprises the steps:

[0041] (1) The nickel-based precursor Ni(OH) synthesized by co-precipitation method 2 ;

[0042] (2) The precursor Ni(OH) 2 and lithium salt LiOH·H 2 O is mixed by ball milling at the ratio of Li / Ni=3:1 in molar ratio, the mixing time is 2h, and the rotating speed is 400rpm to obtain the mixed powder;

[0043] (3) The mixed powder is sintered at 300°C for 2h in a nitrogen atmosphere, sintered at 500°C for 2h, and then sintered at 700°C at a heating rate of 1°C / min for 20h to obtain Li 2 NiO 2 .

[0044] A method for preparing a positive electrode sheet, comprising the following steps:

[0045] (1) Will Li 2 NiO 2 Mix it with nickel-cobalt lithium manganese oxide ternary pos...

Embodiment 2

[0049] The chemical formula of the positive electrode additive of the present embodiment is Li 2 Ni 0.5 Cu 0.5 o 2 , the particle size is D50=4.5μm, and the initial charging capacity is 308mAh / g.

[0050] The preparation method of the positive electrode additive of the present embodiment, comprises the steps:

[0051] (1) The nickel-based precursor Ni synthesized by co-precipitation method 0.5 Cu 0.5 (OH) 2 ;

[0052] (2) The precursor Ni 0.5 Cu 0.5 (OH) 2 and lithium salt LiOH·H 2 O is mixed by ball milling at the ratio of Li / Ni=2.5:1 in molar ratio, the mixing time is 4h, and the rotating speed is 200rpm to obtain the mixed powder;

[0053] (3) The mixed powder was sintered at 200°C for 5h in a nitrogen atmosphere, sintered at 400°C for 4h, and then sintered at a heating rate of 5°C / min to 650°C for 10h to obtain Li 2 Ni 0.5 Cu 0.5 o 2 .

[0054] A method for preparing a positive electrode sheet, comprising the following steps:

[0055] (1) Will Li 2 Ni 0....

Embodiment 3

[0059] The chemical formula of the positive electrode additive of the present embodiment is Li 2 Ni 0.5 mn 0.5 o 2 , the particle size is D50=5.6μm, and the initial charging capacity is 305mAh / g.

[0060] The preparation method of the positive electrode additive of the present embodiment, comprises the steps:

[0061] (1) The nickel-based precursor Ni synthesized by co-precipitation method 0.5 mn 0.5 (OH) 2 ;

[0062] (2) The precursor Ni 0.5 mn 0.5 (OH) 2 and lithium salt LiOH·H 2 O is mixed by ball milling at the ratio of Li / Ni=2.5:1 in molar ratio, the mixing time is 4h, and the rotating speed is 200rpm to obtain the mixed powder;

[0063] (3) The mixed powder was sintered at 200°C for 5h in a nitrogen atmosphere, sintered at 400°C for 4h, and then sintered at a heating rate of 5°C / min to 650°C for 10h to obtain Li 2 Ni 0.5 mn 0.5 o 2 .

[0064] A method for preparing a positive electrode sheet, comprising the following steps:

[0065] (1) Will Li 2 Ni 0....

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com