Semi-solid lithium anode suspension based on lithium nickel cobalt manganate carbon nanotube composite material

A technology of nickel-cobalt lithium manganese oxide and carbon nanotubes, which is applied in positive electrodes, fuel cells, battery electrodes, etc., can solve problems such as increased viscosity and reduced energy efficiency of battery systems, and achieve the effect of improving contradictions and improving electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

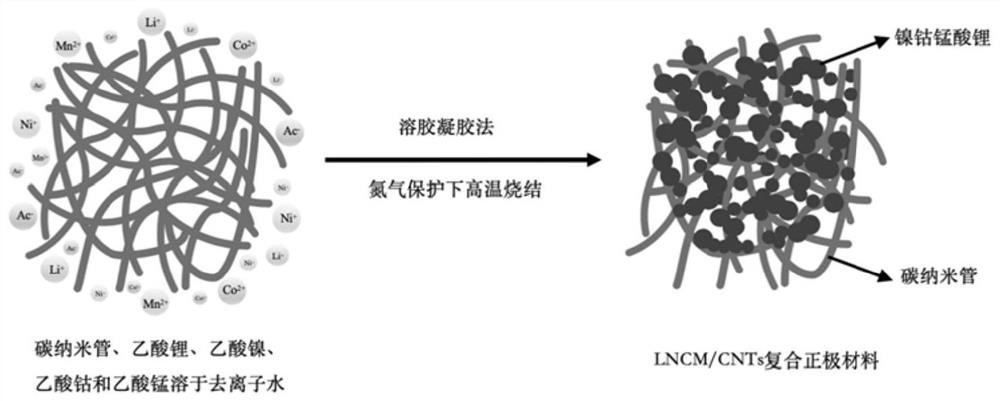

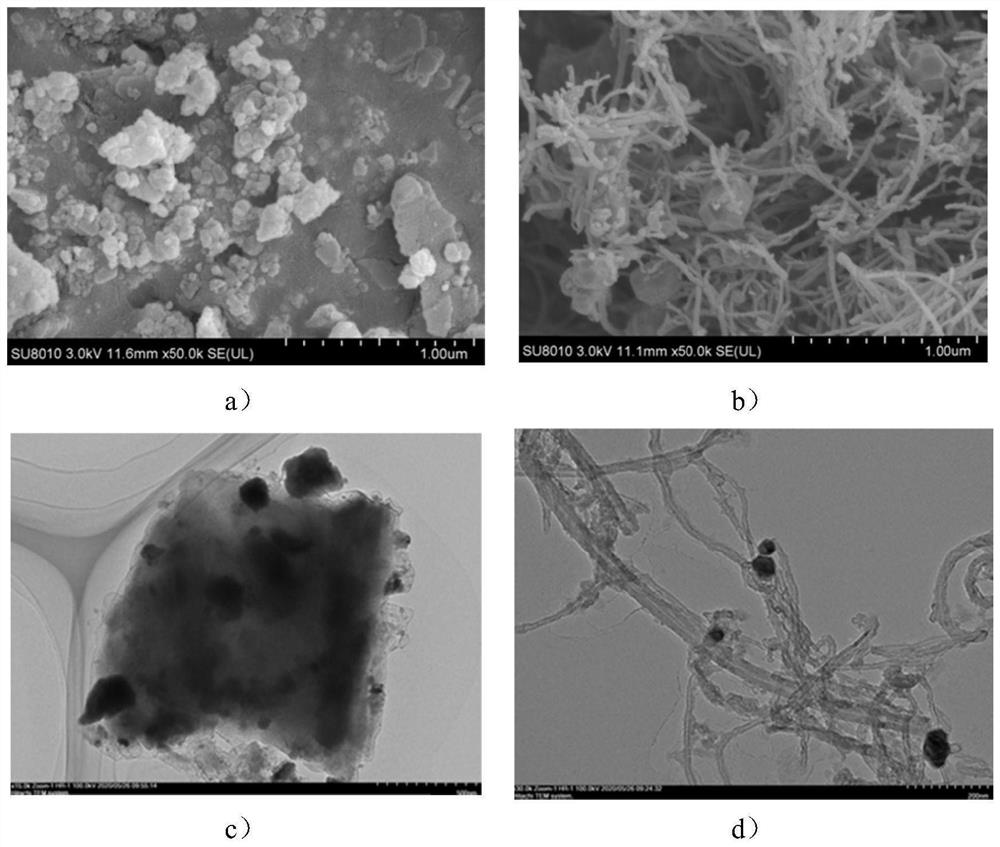

[0041] In this example, two materials, LNCM and LNCM / CNTs, were prepared respectively to compare the differences in their specific technical effects.

[0042] Firstly, the nickel-cobalt lithium manganese oxide / carbon nanotube composite material LNCM / CNTs is prepared, and the basic steps of its preparation are as follows:

[0043] Raw materials include analytically pure CH without any purification treatment 3 COOLi·2H 2 O(≥99.0%), Ni(CH 3 COO) 2 4H 2 O (≥98.0%), Co (CH 3 COO) 2 4H 2 O(≥99.5%) and Mn(CH 3 COO) 2 4H 2 O (≥99.0%).

[0044] 1) The raw materials were dissolved in distilled water to form a brown metal slurry with a Li:Ni:Co:Mn stoichiometric ratio of 3.3:1:1:1, and the excess lithium was used to compensate for the loss during the preparation process.

[0045] 2) Add carbon nanotubes to the brown metal slurry and mix evenly. The amount of carbon nanotubes added should ensure that the mass ratio of carbon nanotubes in the finally prepared LNCM / CNTs is 25%, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com