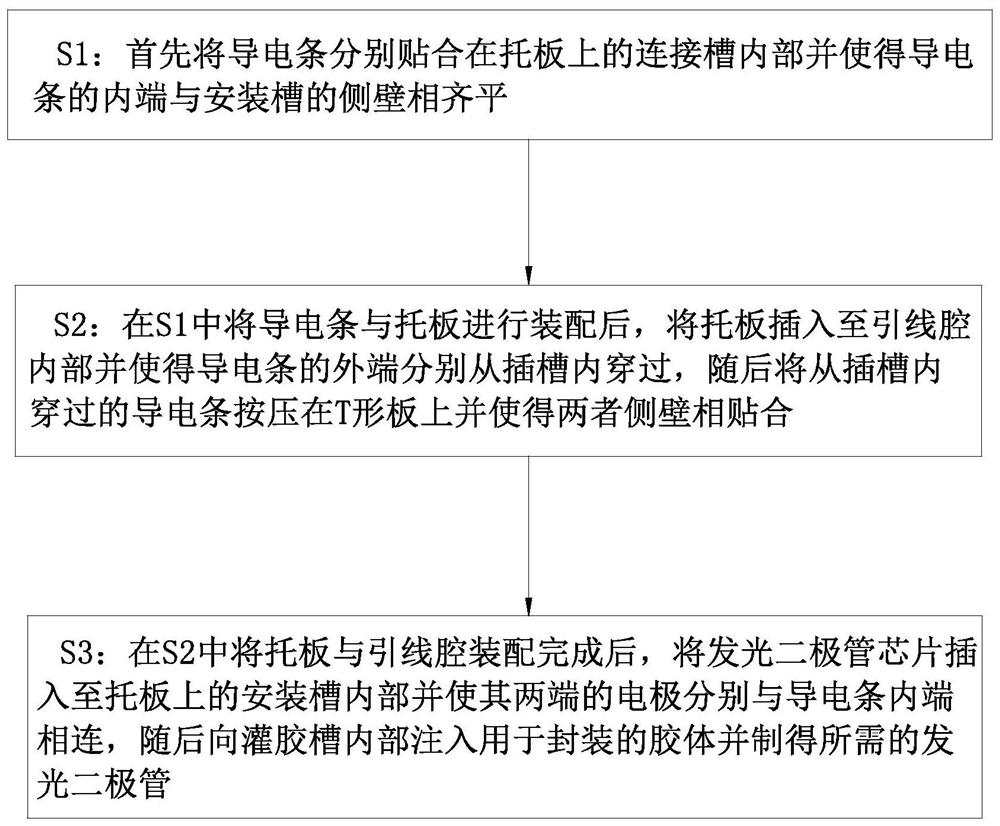

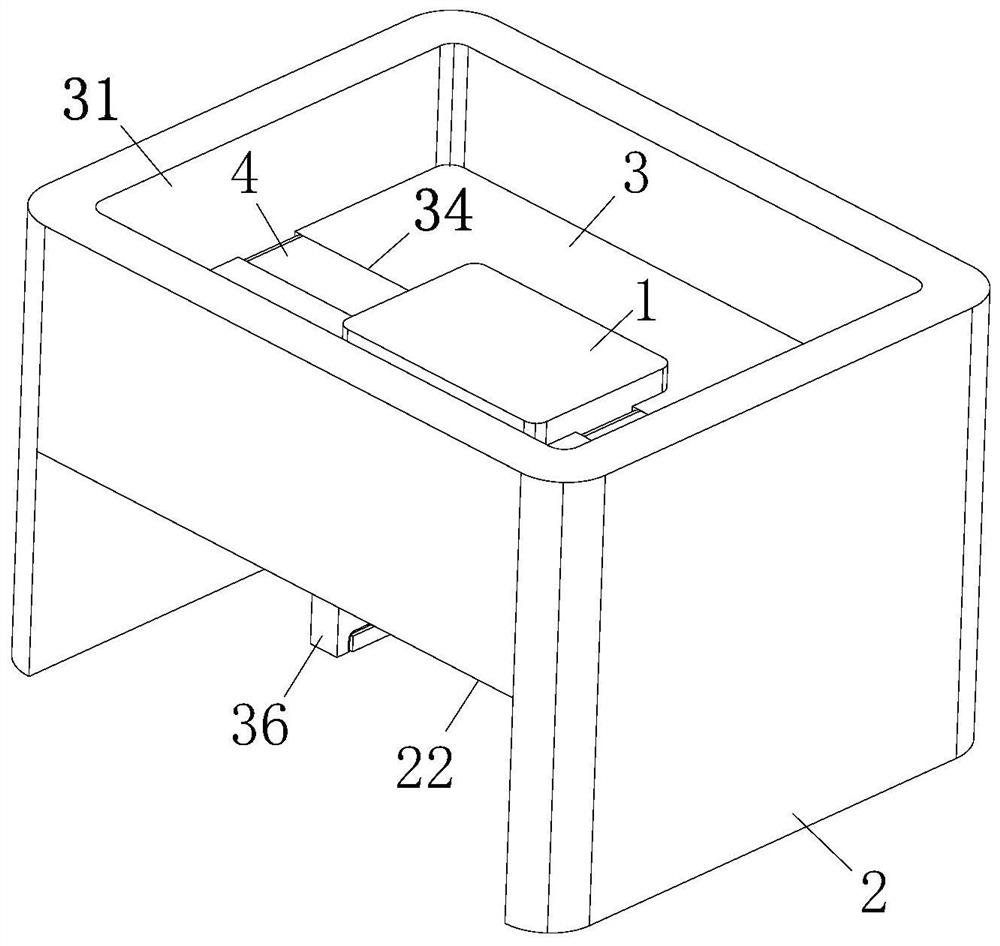

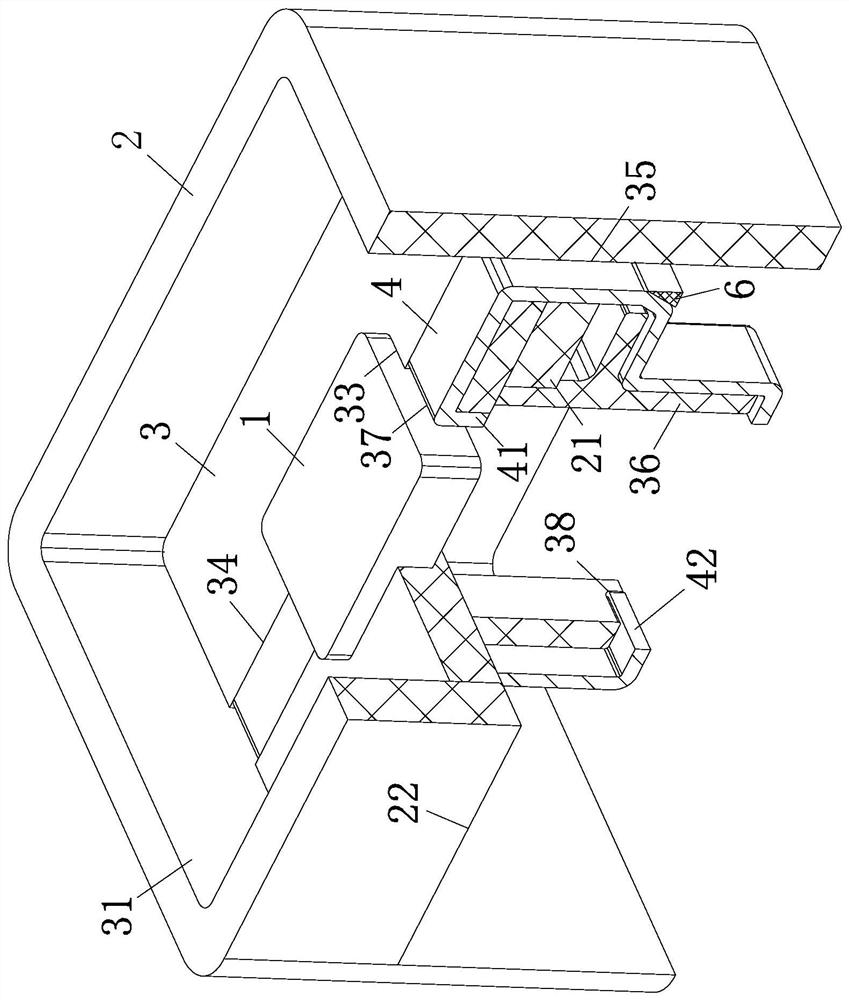

[0007] The technical solution adopted by the present invention to solve its technical problems is: a light-emitting diode according to the present invention includes a light-emitting diode chip; the outside of the light-emitting diode chip is provided with a lead cavity matched with it, and the upper and lower sides of the lead cavity The two ends are connected, and the two inner walls corresponding to the lead cavity along the length direction are symmetrically provided with support plates, and the inside of the lead cavity is installed with a supporting plate capable of sealing the opening of the cavity, and the supporting plate and A glue filling groove is formed between the side walls of the lead cavity, and the inside of the glue filling groove is filled with

colloid; the middle part of the top surface of the supporting plate is provided with a mounting groove matching with the light-emitting diode chip, and the top surface of the supporting plate is symmetrical There is a connection groove connected with the end of the supporting plate and the side wall of the installation groove. A long strip-shaped conductive strip that can be bent freely is bonded inside the connection groove. The inner end of the conductive strip is connected to the side wall of the installation groove. The connecting groove and the outer end of the support plate are respectively provided with through-type slots, the outer end of the conductive strip passes through the slot and is located under the supporting plate, and the bottom surface of the supporting plate is symmetrically provided with T-shaped plate, the outer end side wall of the conductive strip is attached to the T-shaped plate side wall, and the outer end of the conductive strip, the bottom end of the vertical side wall at the T-shaped plate and the bottom of the lead cavity The end faces are flush with each other; the bottom of the lead cavity is provided with a connecting plate that matches it, and a

welding port that can weld the conductive strip and the connecting plate is opened on the side wall of the lead cavity; when working, the light-emitting diode There are problems of large

package volume, cumbersome process and unstable

package when the pin-insert

package is used, while the finished product of the surface

mount package is small in size, but the production cost is high and the production is difficult; and the above two All packaging methods need to pre-connect the light-emitting diode chip and the metal wire, which not only reduces the production efficiency of the light-emitting diode, but also easily causes problems such as poor contact caused by the weak connection between the two; and the light-emitting diode in the present invention is in production , first attach the conductive strips to the inside of the connection grooves on the supporting plate and make the inner ends of the conductive strips flush with the side walls of the installation grooves, then insert the supporting plates into the lead cavity and support them on both sides Cooperate under the action of the board and form a glue filling groove. At this time, the outer ends of the conductive strips are respectively passed through the through-type slots set on the supporting plate and the support plate, and then the conductive strips passing through the slots are pressed on the The T-shaped plate and the side walls of the two are attached together. At this time, the conductive strips and the supporting plate are pre-fixed in the lead cavity by the conductive strips that are attached to the horizontal side walls on the T-shaped plate and are bent. The loosening and detachment of the conductive strip and the supporting plate during the relative movement with the lead cavity in the subsequent packaging process effectively increases the stability of the conductive strip, the supporting plate and the lead cavity during

assembly, and at the same time presses the conductive strip Behind the side wall of the T-shaped plate, the bottom end of the conductive strip is flush with the bottom end face of the lead cavity, so that the conductive strip and the corresponding

electrode end on the connecting plate are welded and connected through the

welding port; After the

assembly is completed, insert the light-emitting diode chip into the installation groove on the support plate and connect the electrodes at both ends to the inner ends of the conductive strips, so that the two poles of the light-emitting diode chip can be easily and quickly connected by contacting the end of the conductive strip. It is connected to the outside, and at the same time, the two ends of the light-emitting diode chip located in the installation groove can be stably connected to the conductive strip, and then the glue is injected into the glue filling groove to complete the packaging of the light-emitting diode, and no other injection molding is required. Or the step of mold forming, which effectively improves the production efficiency and

production quality of light-emitting diodes

Login to View More

Login to View More  Login to View More

Login to View More