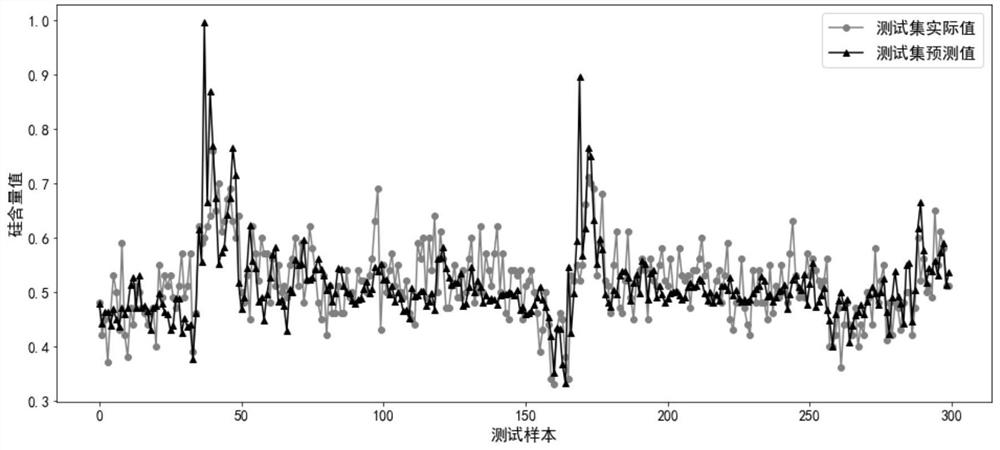

Blast furnace molten iron silicon content prediction method and device based on LSTM & DNN

A technology of silicon content and blast furnace, which is applied in the field of blast furnace molten iron silicon content prediction based on LSTM&DNN, which can solve the problem that a single model cannot take both of them into consideration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The present invention will be further described below in conjunction with accompanying drawings and examples.

[0055] In this embodiment, the 2650m of a domestic iron and steel plant 3 For a blast furnace, the actual blast furnace production data collected from 0:00 on January 1, 2017 to 11:00 on October 13, 2017 is used as an example.

[0056] Such as figure 2 As shown, a method for predicting the silicon content of blast furnace hot metal based on LSTM&DNN model, the specific implementation steps are as follows:

[0057] Step 1: Divide the attributes of the blast furnace data samples, which refers to dividing the lagging influence time of each blast furnace attribute on the silicon content. The specific process is as follows:

[0058] The blast furnace data sample mentioned in step 1) contains the following attributes: record time (c 0 ), oxygen enrichment rate (c 1 ), air permeability index (c 2 ), carbon monoxide (c 3 ), hydrogen (c 4 ), carbon dioxide (c ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com