Magnetic sensing chip, closed-loop feedback current sensor and preparation method of closed-loop feedback current sensor

A current sensor and closed-loop feedback technology, applied in the field of sensing and measurement, can solve the problems of increasing the volume and weight of the current sensor and failing to meet the application requirements of miniaturization, so as to reduce the volume and weight, reduce the volume, and control the production cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

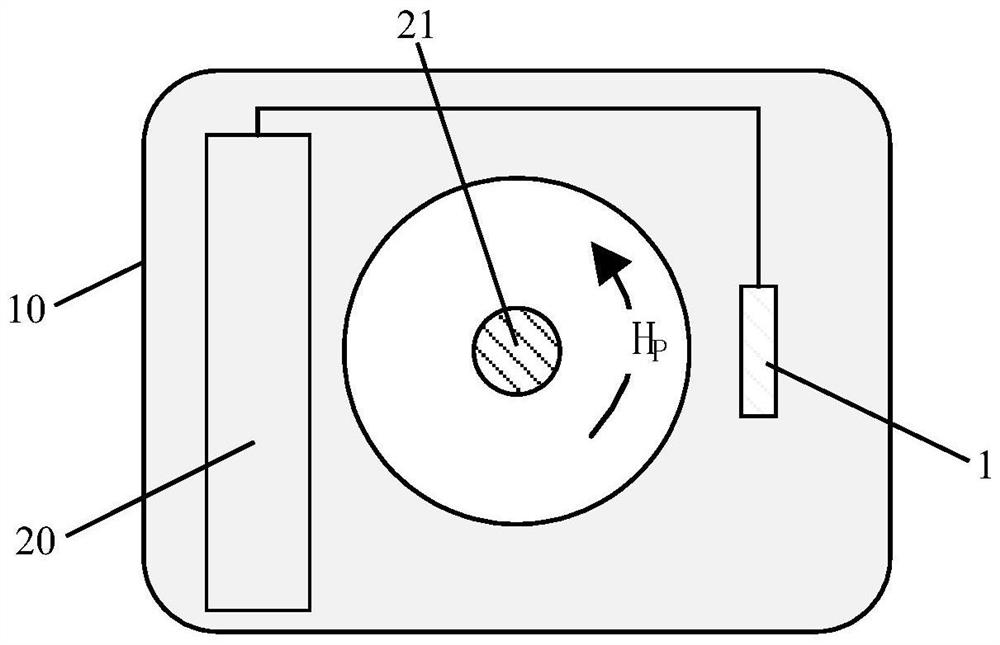

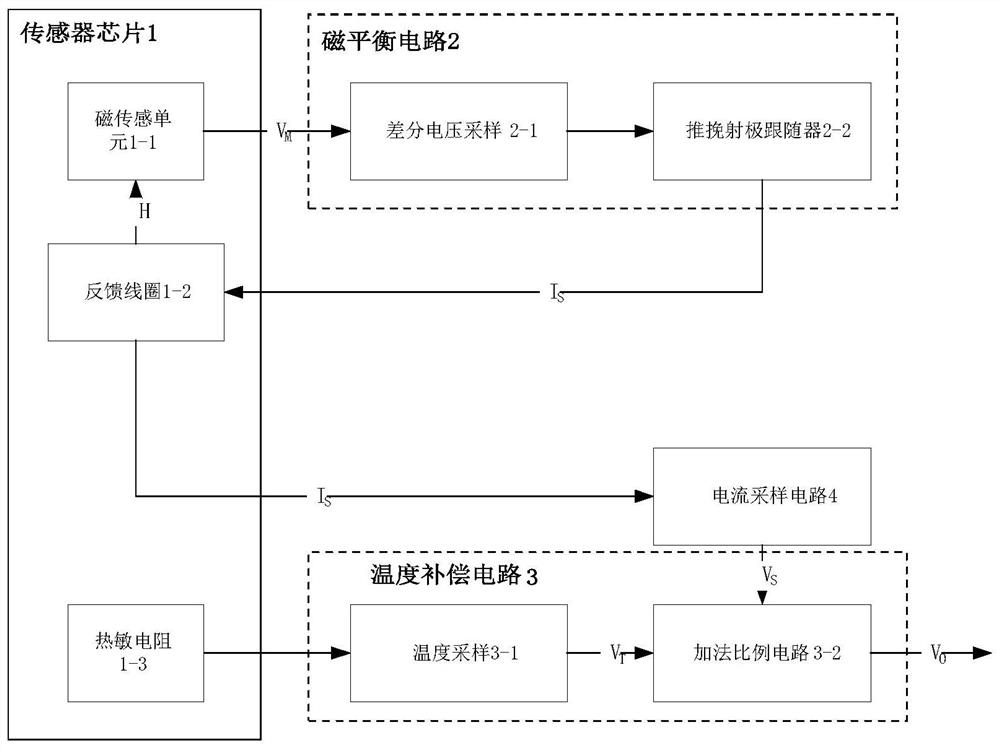

[0040] refer to figure 1 with figure 2 The closed-loop feedback current sensor of this embodiment includes a housing 10, a magnetic sensor chip 1 and a signal processing circuit 20 disposed in the housing 10, wherein the signal processing circuit includes a magnetic balance circuit 2, a temperature compensation circuit 3 and a current sampling circuit 4 . In this embodiment, there is a circular opening in the center of the housing 10, through which the conductor 21 to be tested can pass. The magnetic sensor chip 1 and the signal processing circuit 20 are arranged on the circuit board respectively, the magnetic sensitivity direction of the magnetic sensor chip 1 (magnetic sensor unit) is perpendicular to the conductor 21 to be tested, and the signal processing circuit 20 is connected to the magnetic sensor through pins or wires. The sensor chip 1 is electrically connected. In other embodiments, no opening may be provided on the housing. In this embodiment, an opening is pro...

Embodiment 2

[0057] The difference between this embodiment and Embodiment 1 lies in that in this embodiment, the circuit with the integration link in the signal processing circuit is replaced by digital signal processing, so as to reduce the temperature drift caused by the integration circuit. The signal processing circuit 20 of this embodiment includes a first analog-to-digital converter 2-1, a push-pull emitter follower 2-2, a digital-to-analog converter 2-3, a current sampling circuit 4, a second analog-to-digital converter 2- 5. A temperature sampling circuit 2-6, a third analog-to-digital converter 2-7, and a microcontroller processor 2-8. Wherein, the push-pull emitter follower 2-2 constitutes a magnetic balance circuit, and the temperature sampling circuit 2-6 constitutes a temperature compensation circuit. The first analog-to-digital converter 2-1 is connected with the magnetic sensing unit 1-1, and collects the voltage signal V output by the magnetic sensing unit 1-1 M , and conv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com