Metal nanocrystalline interface carbon base material super assembly controllable growth method

A technology of metal nanocrystals and noble metal nanocrystals, applied in metal material coating technology, nano-carbon, electrolytic coatings, etc., to achieve the effects of strong operability, high yield, and strong universality of the method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Embodiment 1 (Au sphere synthesis)

[0036] 10mL HAuCl 4 (2.5ⅹ10 -4 M) and CTAB (0.1M) mixed solution is placed in a 50mL conical flask, take the existing 10 -2 M NaBH 4 Add 600 μL of the brown solution to the above mixture quickly, place it in a constant temperature shaker at 300 rpm for 2 minutes, and then let it stand at 27°C for 3 hours to make NaBH 4 After fully reacting, the CTAB-coated gold cluster solution was obtained.

[0037] Take 50 μL of the above-prepared gold cluster solution, 2 mL of CTAC (0.2M) solution, 1.5 mL of ascorbic acid AA (0.1 M) solution, mix them in a 20 mL glass reagent bottle, mix well, and add 2 mL of HAuCl at one time 4 (5ⅹ10 -4 M) The solution was reacted at 27° C. for 15 minutes. The product was enriched by centrifugation at 8000rpm for 30 minutes, washed 3 times with deionized water, and finally dispersed in 1 mL of CTAC (2ⅹ10 -2 M) A 10nm gold seed solution was obtained in the solution for later use.

[0038] Take 10 μL of the...

Embodiment 2

[0040] Embodiment 2 (interfacial assembly of Au monolayer film)

[0041] Take 1 mL of the 50 nm CTAC-gold nanosphere solution prepared above and dilute it to 10 mL with water, centrifuge at 8000 rpm for 15 minutes to enrich, remove the supernatant until the volume is less than 200 μL, add 1 mL of 1% PVP / ethanol solution (PVP, Mw=55000) and shake for 30 seconds, keep standing and mix overnight.

[0042] The above mixed solution was centrifuged at 7500rpm for 15 minutes for enrichment, the supernatant was removed, and finally dispersed in 1 mL of ethanol solution to obtain a gold nanosphere solution replaced by PVP on the surface.

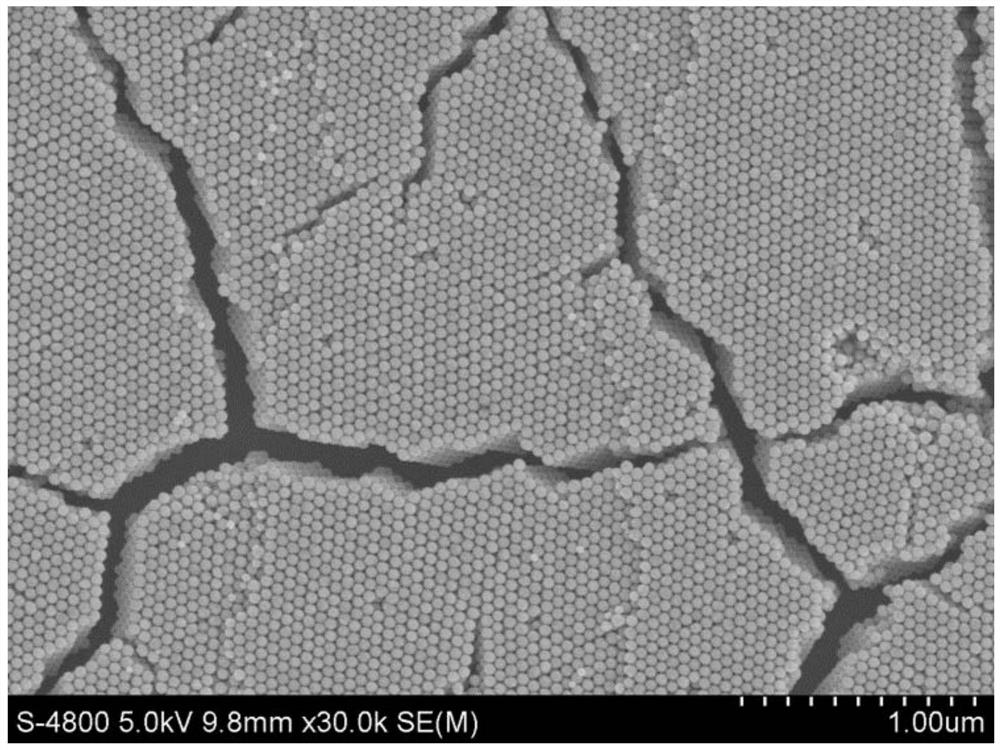

[0043] Take 200 μL of the 50 nm PVP-gold nanosphere solution prepared above, mix it with 800 μL of dichloromethane and 2 mL of deionized water in a centrifuge tube and shake evenly. The solution is in the middle dichloromethane layer, then slowly add n-hexane to the inclined liquid surface until the Au balls form a bright film and let it stand for 2...

Embodiment 3

[0044] Example 3 (AAO@Au interface superassembly)

[0045] Firstly, the prepared AAO porous template was cut into a 1ⅹ1 cm square, the array was ultrasonically cleaned in acetone, ethanol, and aqueous solution for 10 minutes and dried with nitrogen, and soaked in 30% hydrogen peroxide for 2 hours to make the AAO surface Hydroxyl and hydrophilic, wash with water and ethanol to remove the residue and dry.

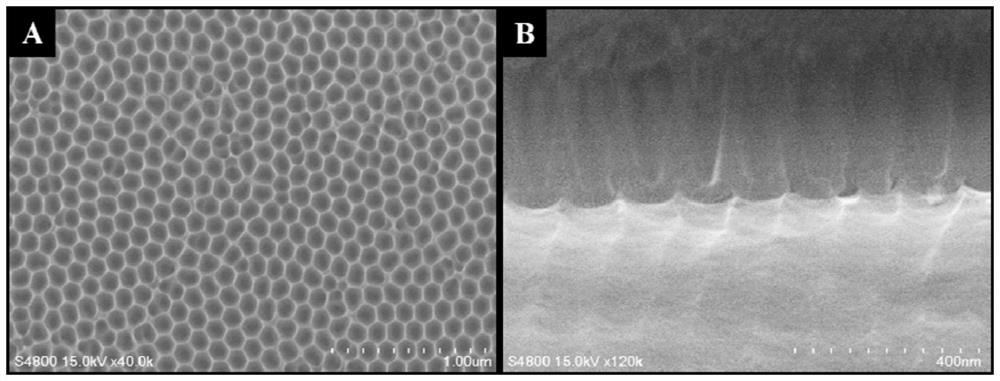

[0046] figure 2 It is the top view and side view of the pre-prepared AAO array structure. It can be seen from the figure that the pore structure presents a uniform V-shaped structure, which is arranged periodically and has good repeatability. Structure, effectively prepared three-dimensional porous array template.

[0047] Hold both sides of the AAO porous template with tweezers so that the front faces up, put the assembled LS gold single-layer film at the edge under the liquid surface and carefully lift it up horizontally, dry it at 50°C and save it for later use, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com