Multilayer stacked adsorption type microalgae biological membrane photobioreactor based on light guide carrier

A technology of photobioreactor and multi-layer stacking, which is applied in the direction of photobioreactor, special-purpose bioreactor/fermenter, microorganism-based method, etc., can solve the difficult problem of microalgae biofilm receiving light, and the Low biomass production, large footprint and other issues, to achieve excellent light transmission performance, increase microalgae biomass production, and low power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

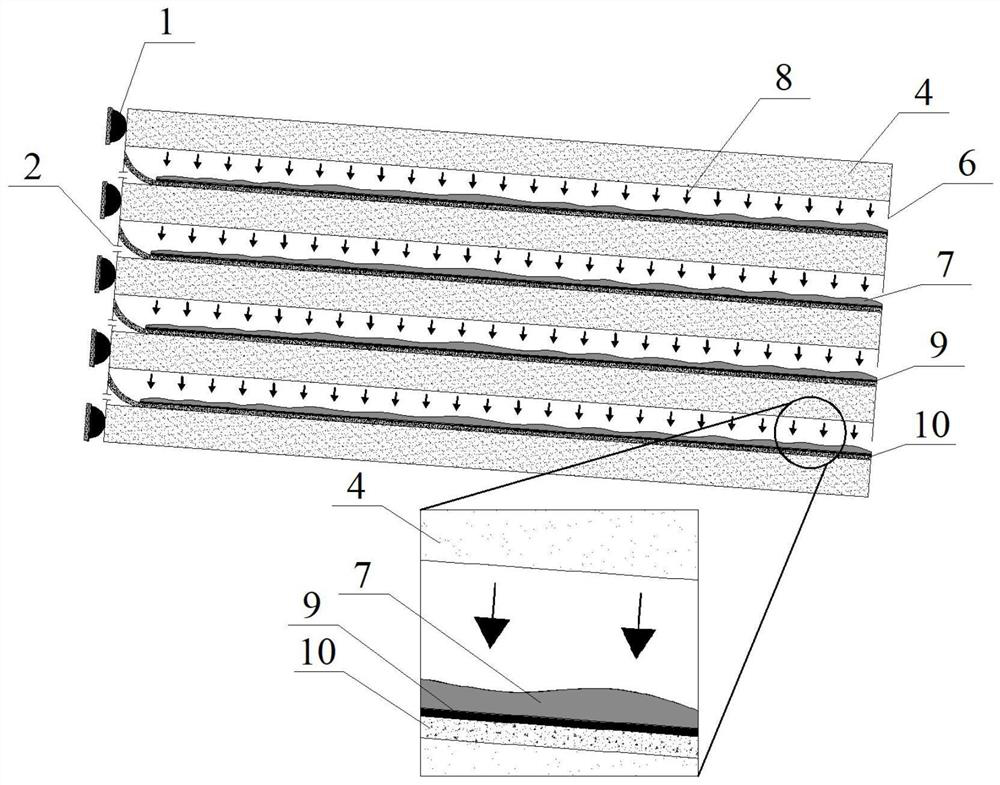

Embodiment 1

[0025] A multi-layer stacked adsorption microalgae biofilm photobioreactor based on a light guide carrier, the reactor bracket 3 is processed by 304 stainless steel angle steel, the angle between the solid light guide plate 4 and the horizontal plane is 5°; LED light bar 1 The 2835 type white LED light bar is selected, and the LED light bar is driven by a 24V DC power supply, so that the average light intensity of the light emitted from the lower surface of the solid light guide plate 4 is 100 μmolm -2 the s -1, and the LED light bar is continuously working 24 hours a day, providing continuous and constant light conditions for the growth of algae cells; the solid light guide plate 4 uses a PMMA / PS nano light guide plate with a thickness of 4 mm, except for the incident end surface of the LED light bar and the light guide plate. Except for the lower surface of the light plate, the rest of the surface is pasted with a reflective film with a thickness of 0.1 mm and a light refle...

Embodiment 2

[0027] A multi-layer stacked adsorption microalgae biofilm photobioreactor based on a light guide carrier, the solid light guide plate 4 is a PMMA laser engraved light guide plate with a thickness of 6 mm, the porous material liquid culture medium source layer 10 is filter cloth, and the microporous The filter membrane 9 is a nylon membrane with an average pore size of 0.22 μm, and the other parts are the same as in Example 1.

Embodiment 3

[0029] A multi-layer stacked adsorption microalgae biofilm photobioreactor based on a light guide carrier, the solid light guide plate 4 is a PS screen printing light guide plate with a thickness of 4 mm, the porous material liquid culture medium source layer 10 is filter paper, and the microporous The filter membrane 9 is a polyvinylidene fluoride membrane with an average pore size of 1.2 μm, and the other parts are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com