Method for preparing nano zirconium oxide by internal gel method

A nano-zirconia and zirconium oxychloride technology, applied in the field of material science, can solve the problems of easy agglomeration of zirconia powder and narrow particle size distribution, and achieve the effects of easy reaction, uniform size and good dispersion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

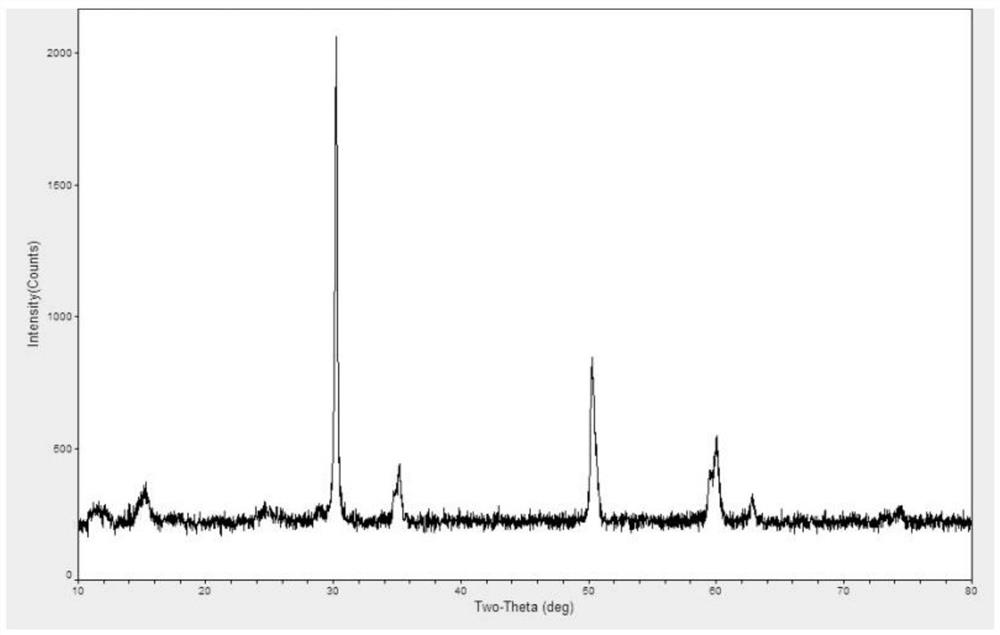

Embodiment 1

[0038] Weigh 171.2g of zirconium oxychloride (containing crystal water) and 11.85g of yttrium nitrate hexahydrate in the ratio of 3Y, and dissolve them in 250ml of deionized water; weigh 33g of urea and dissolve them in the zirconium solution; weigh 70g of organic monomer : acrylamide, and 3g of cross-linking agent: N, N'-methylenebisacrylamide, dissolved in the above mixed solution; take 5g ammonium persulfate, 2ml tetramethylethylenediamine, add to the solution, stir Evenly and heat to 80°C, wait for 30min, after it is completely gelled, take it out and cut it into small squares of about 0.5mm; soak the small gel pieces in distilled water to wash-filter, repeat several times until the filtrate The chloride ion content is less than 20ppm, and then the colloidal particles are filtered and dried (90°C—110°C); the dried colloid is calcined at a high temperature of 800°C for 4 hours to obtain nano-zirconia powder with good dispersion; The specific surface area of the powder mea...

Embodiment 2

[0040] Weigh 171.2g of zirconium oxychloride (containing crystal water), 5.2g of magnesium chloride, and dissolve them in 250ml of deionized water; weigh 33g of urea and dissolve them in the zirconium solution; weigh 70g of organic monomers: acrylamide, and 3g of Cross-linking agent: N, N'-methylenebisacrylamide, dissolved in the above mixed solution; take 5g of ammonium persulfate and 2ml of tetramethylethylenediamine, add them to the solution, stir evenly and heat to 80°C, Wait for 30 minutes, after it is completely gelled, take it out and cut it into small squares of about 0.5mm; soak the small gel pieces in distilled water to clean-filter, repeat several times until the chloride ion content of the filtrate is less than 20ppm, Then filter and dry the colloidal particles (90°C—110°C); place the dried colloid at a high temperature of 800°C for 4 hours to obtain nano-zirconia powder with good dispersion; measure the powder with a specific surface area meter The specific surfac...

Embodiment 3

[0042] A kind of method for preparing nano zirconia by inner gel technology, is characterized in that, comprises the following steps:

[0043] Step 1: Mix soluble zirconium source and soluble yttrium source, mix with deionized water, and prepare solution A of 0.5-2.0mol / L, the total weight of zirconium source and yttrium source is M1, and the molar ratio zirconium: urea is 1: 1.1 Weigh urea and add it to solution A to obtain solution B; the soluble yttrium source is any one or two of yttrium chloride, yttrium oxalate, yttrium nitrate, and yttrium acetate; the soluble zirconium source is oxychloride Any one or both of zirconium oxide and zirconium acetate; the molar ratio of zirconium and yttrium in the reaction solution A is 97:6;

[0044] Step 2: Weigh acrylamide with a weight of M2 and N, N'-methylenebisacrylamide with a weight of M3, and put them into solution A for dissolution to obtain solution C, wherein M2:M1 is 1:4-1:3 , M3:M2 is 1:30-1:15;

[0045] Step 3: adding am...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com