A fully automatic filling production line for cosmetics

A cosmetic, fully automatic technology, applied in the field of machinery and equipment, can solve problems such as wasting manpower and reducing work efficiency, and achieve the effects of reducing labor intensity, saving settings, and facilitating operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

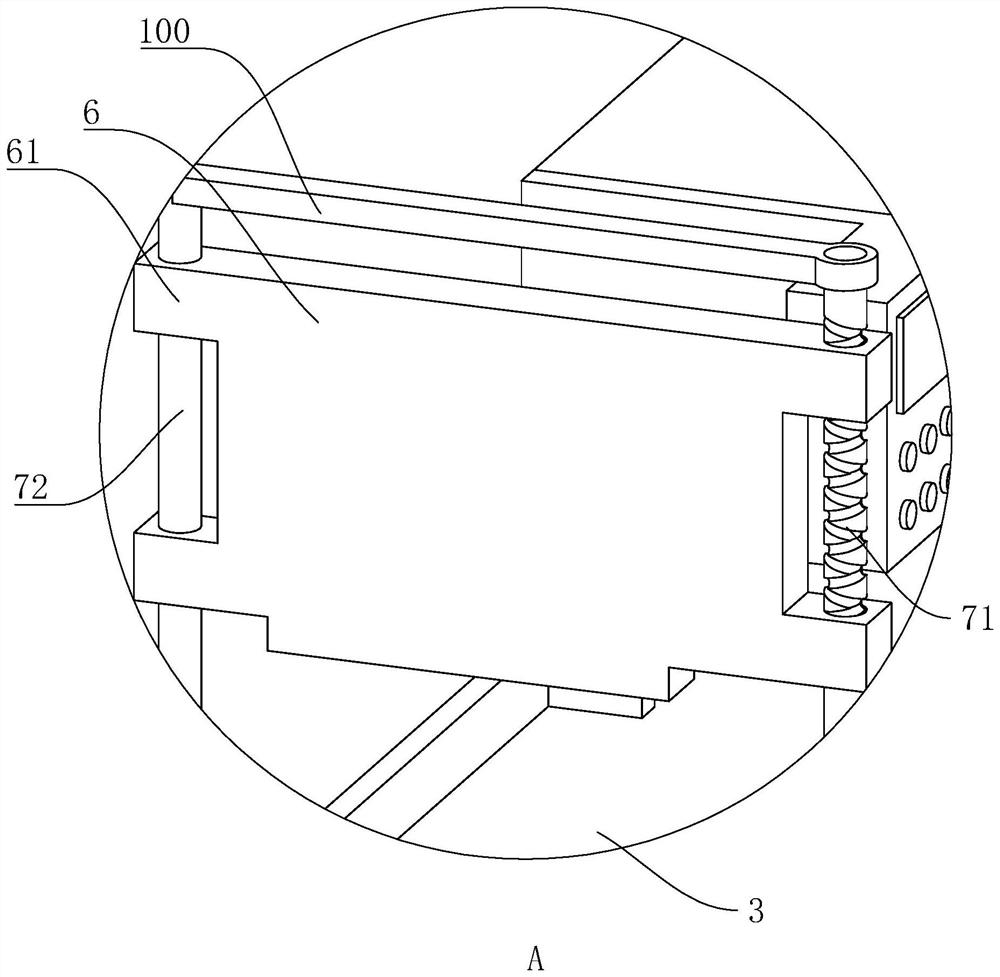

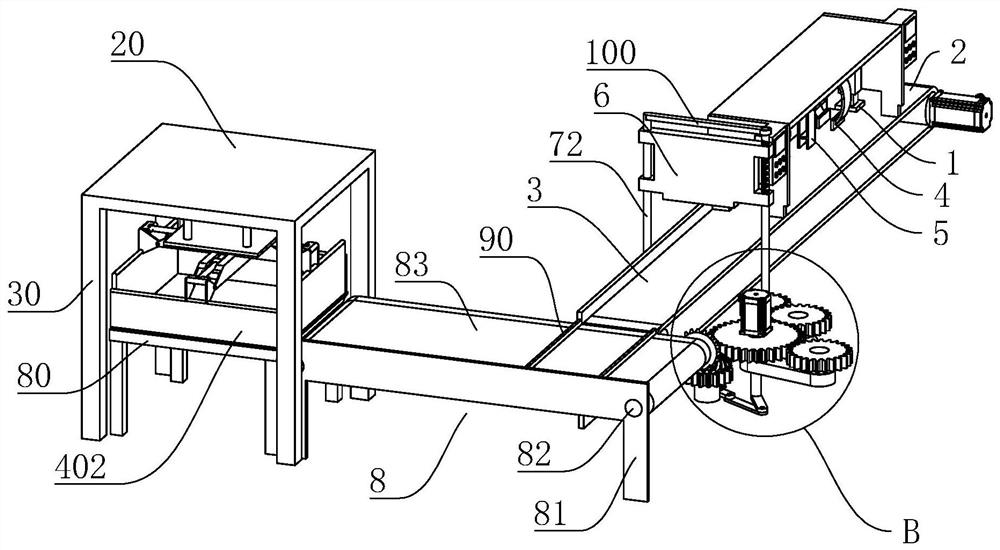

[0039] The application will be described in further detail below in conjunction with the accompanying drawings.

[0040] refer to figure 1 , is a fully automatic cosmetics filling production line disclosed in the present application, comprising a liquid filling device 1, one side of the liquid filling device 1 is provided with a bottle-inlet conveying device 2, and the other side is provided with a bottle-out conveying device 3, The conveying directions of the bottle conveying device 2 and the bottle conveying device 3 are in a straight line, and cap installation and pressing devices are arranged sequentially from the connecting end of the bottle conveying device 3 and the bottle entering conveying device 2 to the end of the bottle conveying device 3 4. The code sticking device 5, when in use, places the empty cosmetic bottles one by one on the inlet end of the bottle-in conveyor 2, the distance between the two sides of the bottle-in conveyor 2 and the two sides of the bottle-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com