Cutter damage real-time monitoring method based on spindle vibration feature fusion

A technology of real-time monitoring and feature fusion, applied in the direction of manufacturing tools, measuring/indicating equipment, instruments, etc., can solve a lot of time and cost, lack of physical modeling, indirect monitoring methods can not determine the cutting load and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0115] The present invention will be described in detail below with reference to the drawings and embodiments.

[0116] A real-time monitoring method for tool damage based on spindle vibration feature fusion, including the following steps:

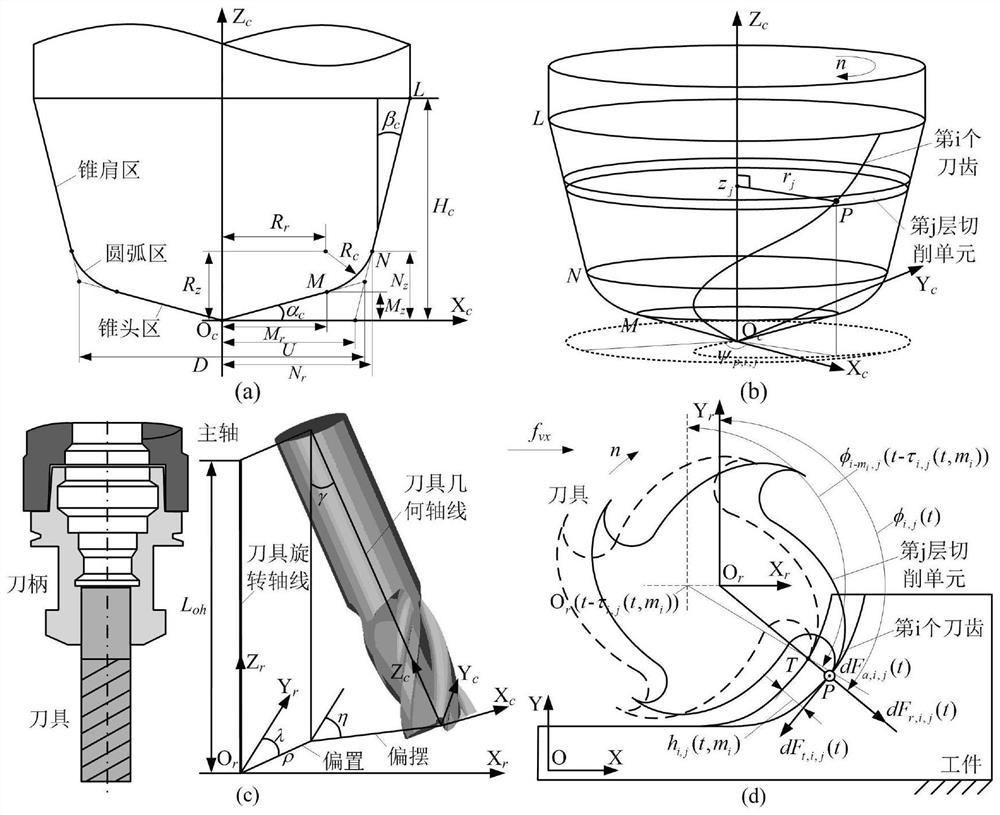

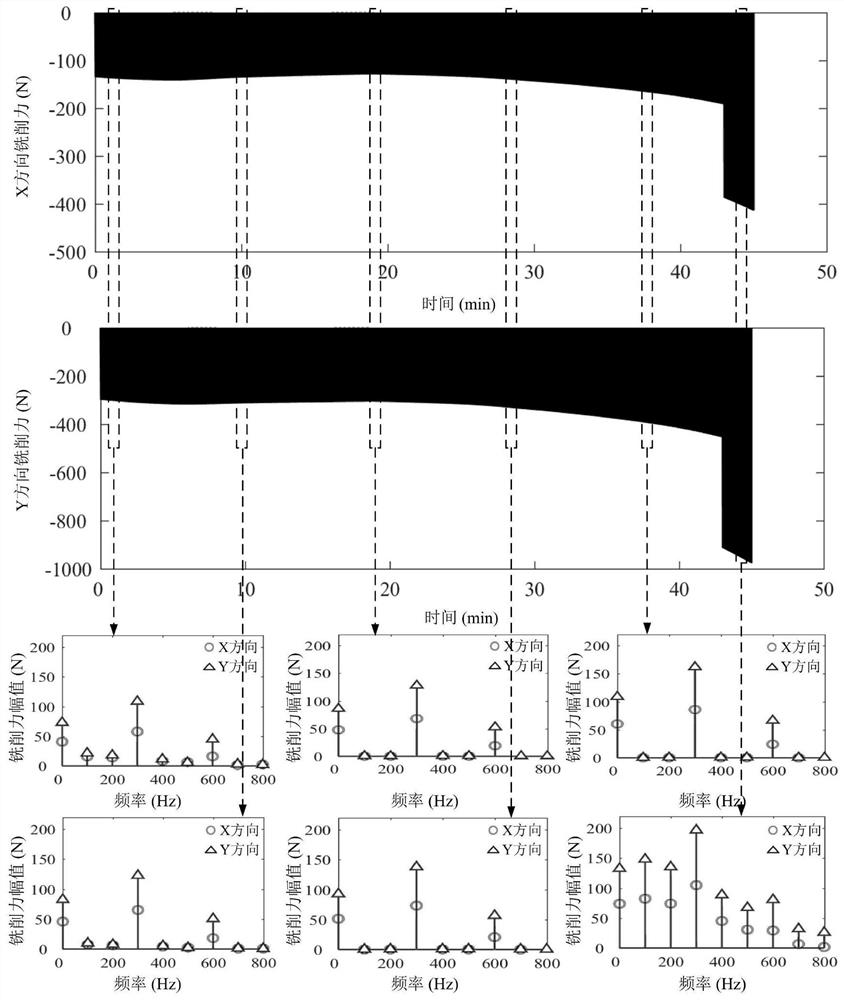

[0117] Step 1) For the milling process, analyze the tool damage process, establish a calculation model of the cutting layer thickness considering the tool eccentricity and damage, calculate the milling force, and analyze the time domain and frequency domain characteristics of the milling force;

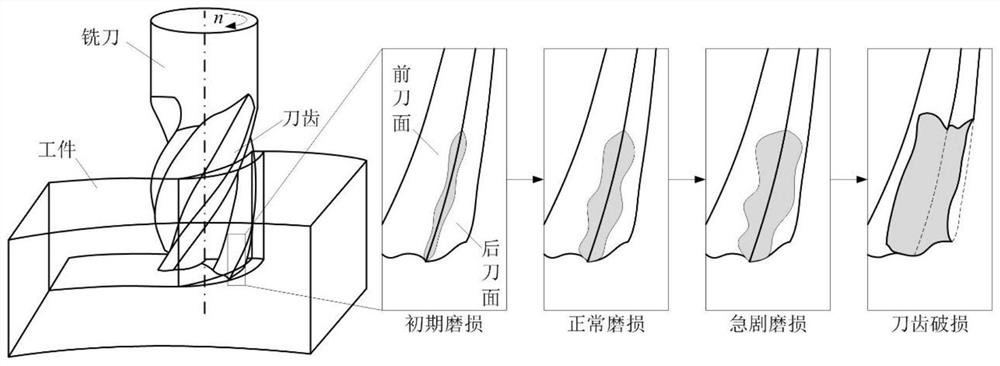

[0118] 1.1) The damage process of the tool in the milling process:

[0119] Such as figure 1 As shown, during the machining process, the cutting force and cutting heat will be generated when the tool and the workpiece are in contact, which will cause the front and rear face of the tool teeth to wear under the effect of thermal coupling. After the tool wears, it will cause the increase of the cutting force, especially It is the alternating force, friction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com