Sheet metal machining method for automatically polishing hole based on punching potential energy

A processing method and punching technology, which is applied in the field of sheet metal processing, can solve the problems of reducing the efficiency of sheet metal processing and the inability to grind the inner wall of the hole, so as to achieve the effects of improving efficiency, ensuring tightness, and avoiding environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

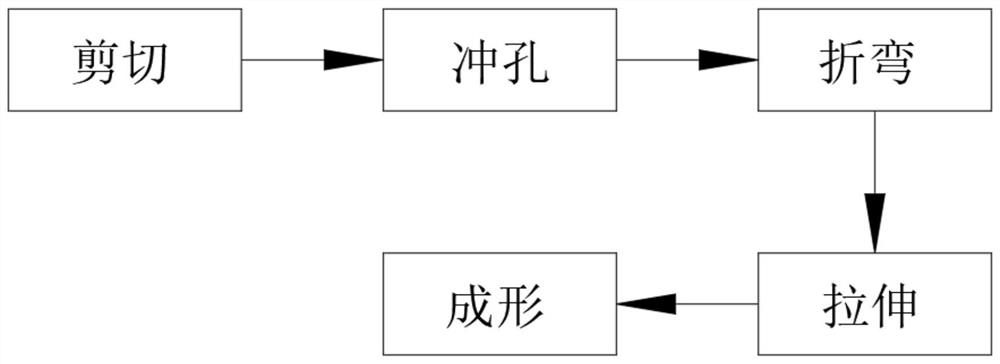

[0032] Such as Figure 1-5 As shown, a sheet metal processing method for automatically grinding holes based on punching potential energy mainly includes the following steps:

[0033] S1 cutting, cutting the metal sheet to the required size through the shearing machine;

[0034] S2 punching, through the punching equipment to punch out the required holes on the plate obtained in S1;

[0035] S3 bending, bending the plate punched by S2 through a bending machine to obtain the plate that needs to be bent;

[0036] S4 stretching, stretching the plate obtained in S3 into the desired shape through stretching equipment;

[0037] S5 forming, placing the plate obtained in S4 on the punching machine, and shaping it into the desired product through the mold;

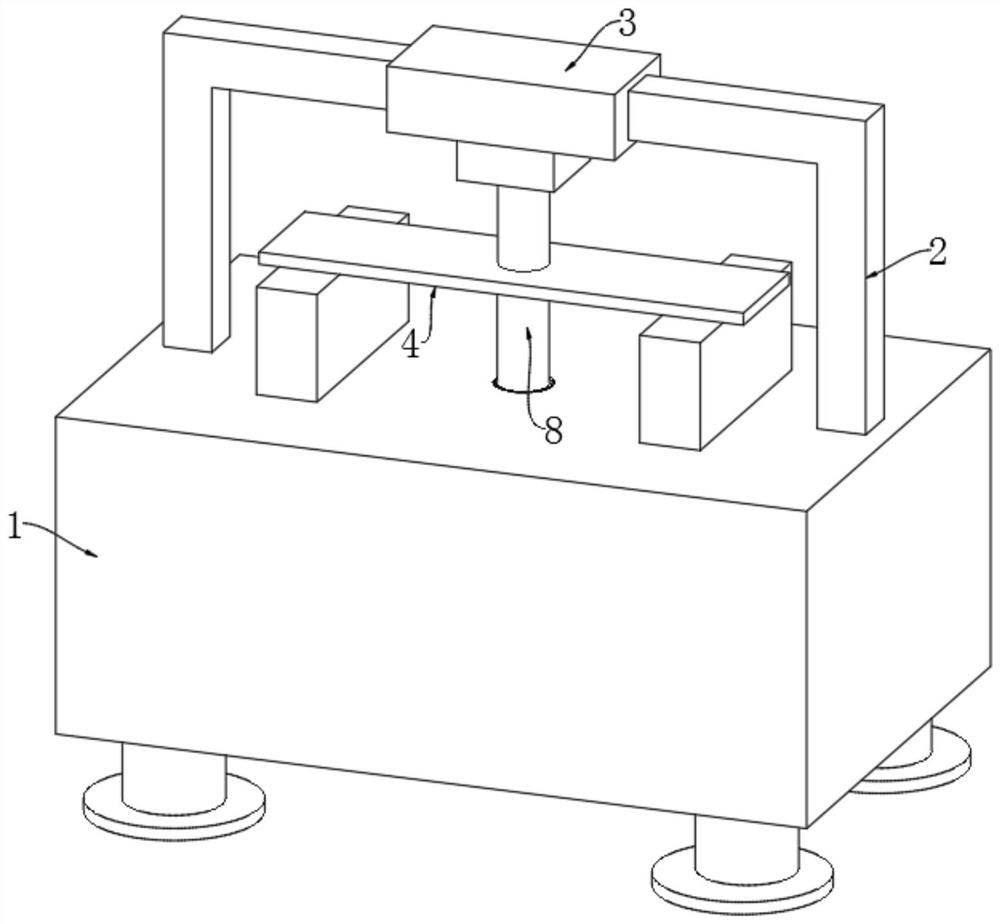

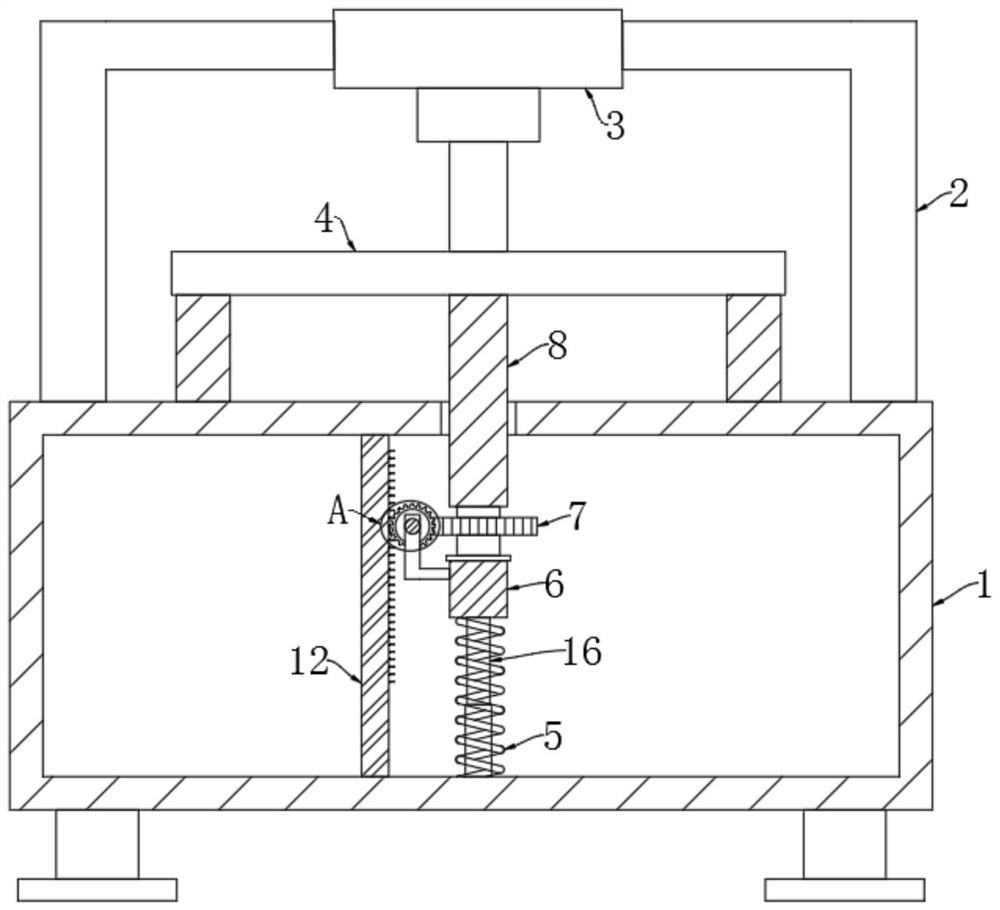

[0038] The punching equipment used in the above sheet metal processing process includes a box body 1, a bracket 2 is fixedly connected to the box body 1, and a puncher 3 is arranged on the bracket 2, a metal sheet 4 is placed on t...

Embodiment 2

[0043] Such as Image 6 As shown, the difference between this embodiment and Embodiment 1 is that: a piston chamber 17 is provided in the box body 1, and a piston 18 is slidably connected to the piston chamber 17, a magnetic rod 19 is fixedly connected to the support block 6, and the magnetic The end of the rod 19 away from the support block 6 is slidingly connected to the side wall of the piston chamber 17, the magnetic rod 19 is attracted to the sliding end on one side of the piston 18, the piston chamber 17 is connected with a suction pipe 20, and the suction pipe 20 is arranged through the casing 1, The piston chamber 17 is fixedly connected with a filter screen 21, and the filter screen 21 is made of a magnetic material. The feed inlet of the suction pipe 20 is a tapered design, and the suction pipe 20 is provided with a one-way valve 22. The cone of the suction pipe 20 feed inlet Shaped design can enhance the airflow pressure during the suction process and improve the me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com